DATA SHEET

TS1212 Precision Pinch Tube Valve

Willow House

20 Craigmore Ave

Milton Keynes, MK3 6HD

United Kingdom

Tel +44 (0) 845 652 0058

Fax +44 (0) 845 652 0059

info@adhesivedispensers.co.uk www.adhesivedispensers.co.ukAdhesive Dispensing Ltd

Sales & Service

Freephone 0800 094 9058

Registered in England & Wales

Reg. No 6048283

VAT No. 901 8594 21

Product Description

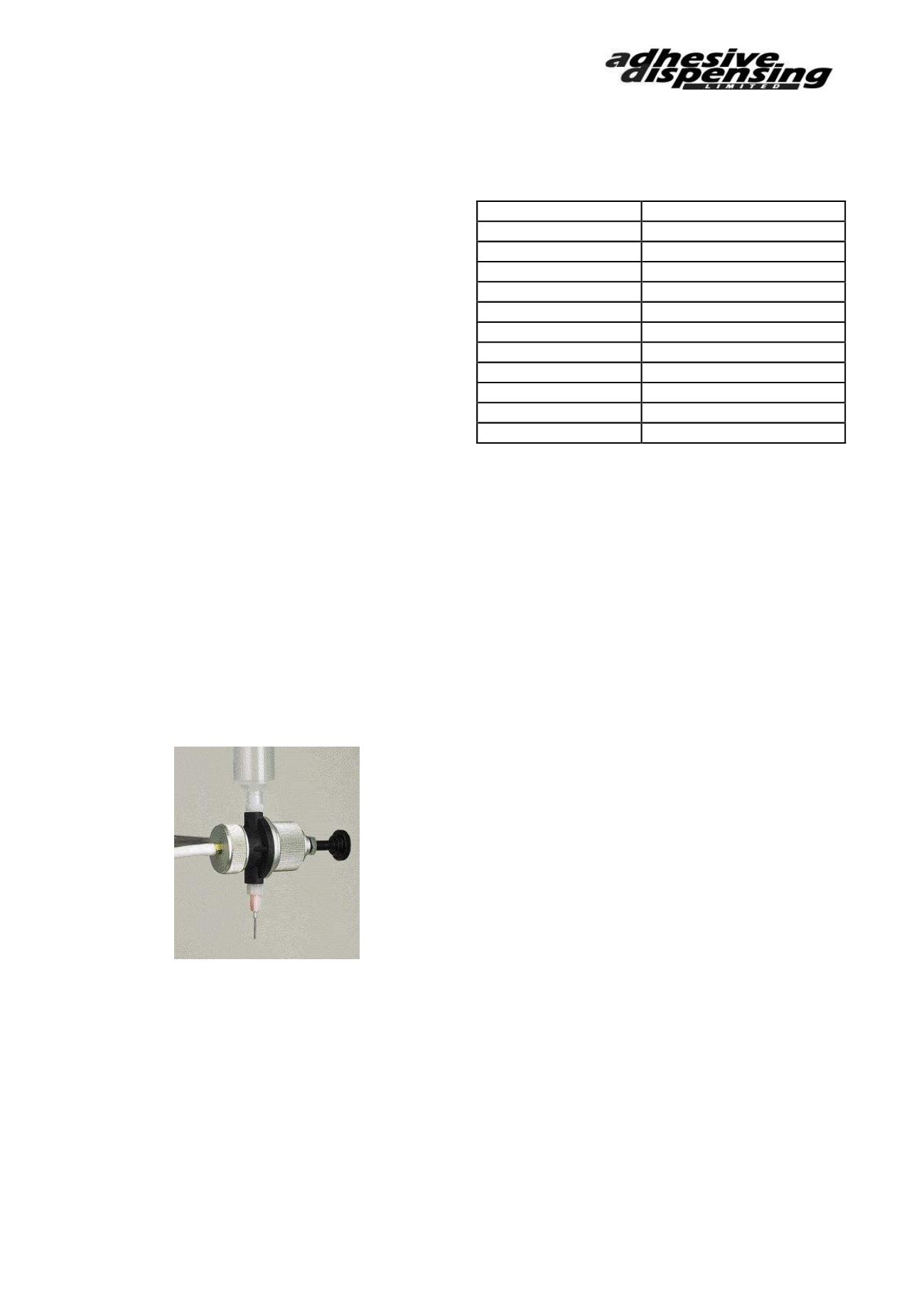

The TS1212 is a pneumatic controlled precision valve for

applying repeat deposits of most low to medium viscosity

liquids and adhesives. It accepts a feed of fluid direct from a

syringe, cartridge or pressure pot. The ‘wetted’ parts the

liquids touch are resistant to clogging and can be replaced

to prevent maintenance.

Typical Applications

The TS1212 will dispense most low to medium viscosity

adhesives, liquids, cyanoacrylates, UV, primers, activators,

epoxies, inks, solvents and chemicals. The TS1212 uses

pinch tubes which are low cost and take seconds to replace

making this valve maintenance free and ideal for curing

epoxies. The TS1212 is supplied with fittings, clear and

black fluid lines, pinch tubes and a selection of needle tips.

Instructions For Use

1. Attach a needle tip (supplied) to male luer end.

2. Attached a fluid line (supplied) to female luer input.

3. Connect the fluid line to a pressure pot, syringe or cartridge.

4. Set fluid pressure if regulated on your tank.

5. Connect TS1212 airline (supplied) to a pneumatic valve

controller, such as our TS250.

6. Purge fluid line for adhesive to flow to valve. Once TS1212 is

pulsed from pneumatic dispenser, deposit will be made.

7. Use smaller tips for finer control, larger tips for faster flow and

adjust the stroke control on the side of valve.

8. Use tip cap seal (supplied) when dispensing finished and to cap

off air tight.

Spare components are available to order from stock such as

fittings, pinch tubes, needle tips and fluid lines.

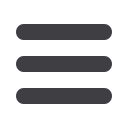

Technical Information

Size:

3.25” x 1.58”

Colour:

Black/ Silver

Weight:

82 gram

Flow Rate:

0.54 gal/min (Water) at 60 psi

Max Fluid Pressure:

60 psi (4 bar)

Repeatability:

±0.56%

Min Shot Size:

0.007cc or ml

Fluid Viscosity Range:

Up to 45,000 CPS

Material Inlet:

Female luer lock

Material Outlet:

Male luer lock

Actuation Air Pressure:

50 psi (3.4 bar) minimum

Wetted Parts:

Polyethylene

Options

The TS1212 is also available with our range of pressure

pots from 500 gram to 19 litre and our digital valve

controllers TS250, TS350 or TS500R.

Warranty

The TS1212 Valve is provided with a 12 month warranty

against product fault or defect.

Health & Safety in Use

The TS1212 is safe, reducing risk of operator contact with

the materials being dispensed and reducing fumes. This

valve can be hand held or bench/ machine mounted for use

over long periods of time which minimises the risk of

repetitive strain injury compared to manual dispensing.

Benefits

•

Zero maintenance pinch tube valve

•

Lightweight, compact, low cost

•

Handles many liquids including reactive adhesives

•

Adjustable stroke control

•

Robust material construction

•

Provides fast, repeat deposits up to 500/minute

•

Ideal for Cyanoacrylates

•

12 Month Warranty

The data, information and values contained in this Technical Data Sheet have been obtained by specific tests conducted in a controlled environment, and

should be used for guidance purposes only. Although we believe them to be reliable and accurate, users should always conduct their own tests in their specific

working conditions to ensure that the product is suitable and effective for use. It is the user’s sole responsibility to determine the suitability of the product for the

application. Adhesive Dispensing Ltd cannot be held responsible for the results of procedures undertaken elsewhere, nor for the safeguarding of personnel or

property, all of which is the duty of the user. Suitability of products or methods is discretionary. Therefore, warrantees or implied usage obligations should not

be attributed to, and are not the responsibility of, Adhesive Dispensing Ltd. Adhesive Dispensing Ltd are not liable for any financial loss or other damages

incurred by the user as a result of the use of this product. Product dimensions and design are approximate and can be subject to change, without notice.