March 2015

48

www.read-eurowire.comNews

Technology

I.LE.S. Industrial Furnaces in Pianengo, Italy, has introduced

a new range of unattended automatic lines for stabilisation,

tempering, structural hardening, ageing, pre-heating, and

stress-relieving heat treatments.

These lines are composed of the following main system

components:

•

Horizontal chamber electric furnace, with forced air

circulation and 700°C maximum working temperature,

with high thermal efficiency obtained by insulation with

the more advanced ecological ceramic fibres, assembled

in several layers with differentiated density, without

thermal bridges; heating with massless wire elements,

placed directly into the air circuit; using a patented

system of vitrification of the surfaces which are in

contact with the air; assembling specially shaped baffle

and fan for the air circulation. All of these elements

allow a temperature uniformity obtained spatially in the

treatment chamber, according to AMS 2750 E and CQI9

standards requirements

•

Storage system with two, four, six or eight positions

Main characteristics include:

•

Useful load for each position of the storage system from

500 to 3,000kg

•

Specific software for managing the line with no operator

•

Saving of up to 60 different thermal cycles

•

Supervisor system with advanced diagnostics, for

monitoring of the production as well as for detecting

anomalies

•

SMS telecommunication system, to send diagnostic

messages to different users, according to the occurred

event

•

Paperless recorder for product certification, arranged to

be linked to the company’s network

•

Air cleaner for smoke and smells

I.LE.S. Srl – Italy

Website

:

www.iles.itNew range of

unattended

automatic lines

▼

▼

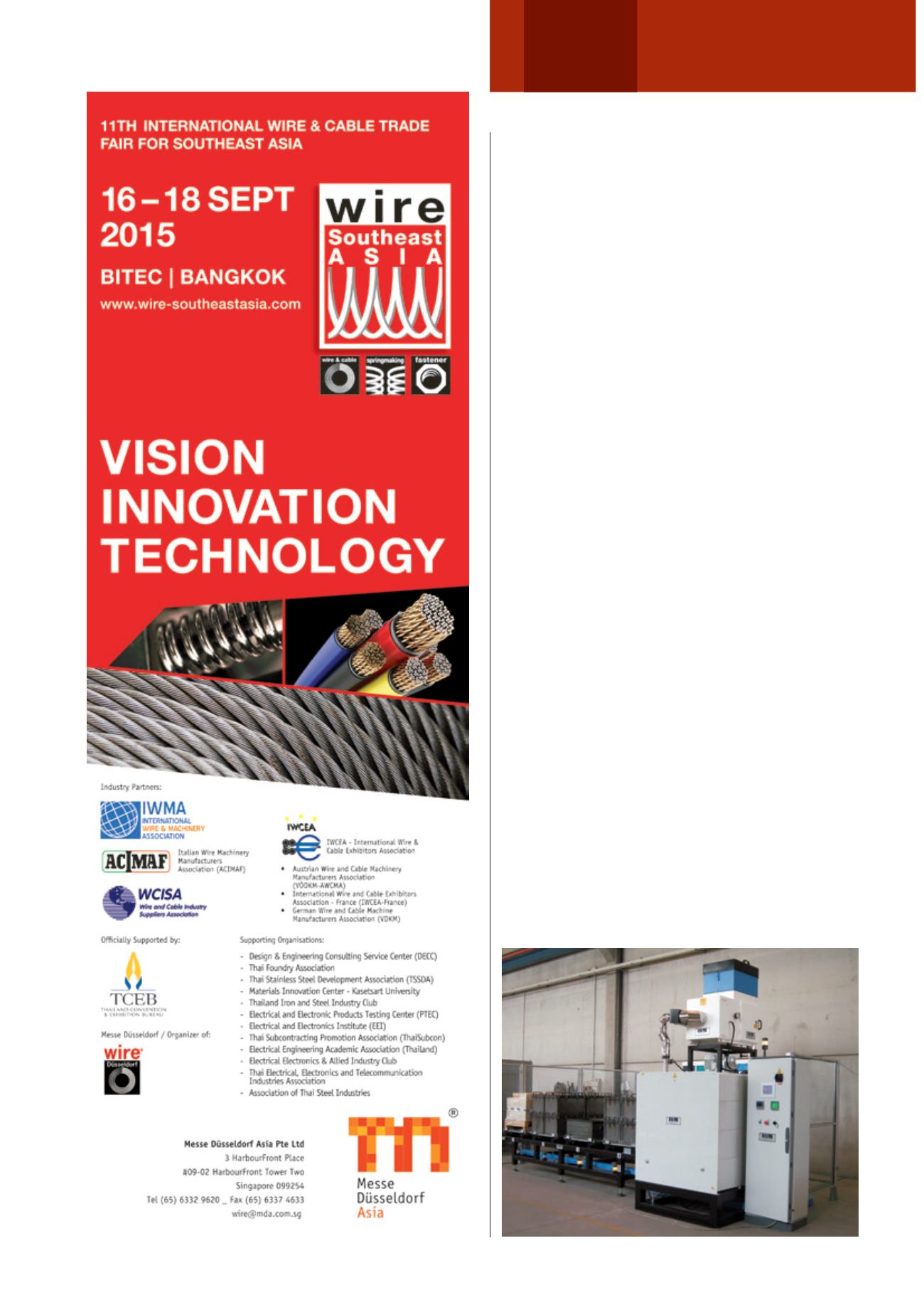

Part of the range on offer from I.LE.S.