CAPITAL EQUIPMENT NEWS

MAY 2016

4

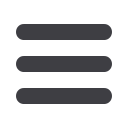

O

ver the past few years Volvo CE has

launched a number of state-of-the-

art road building and construction

machines that offer reduced noise and emis-

sions, greater fuel and operational efficiency

and unparalleled operator comfort.

Dating back to the 1950s, Volvo CE has had an

illustrious history in the wheel loader sector. De-

fined by innovation, this legacy is set to continue

as the company enters a new era of construc-

tion machinery and road building excellence.

In the next few years, Volvo CE plans to add

to its already extensive portfolio of road

building products with its most advanced

and energy efficient range yet.

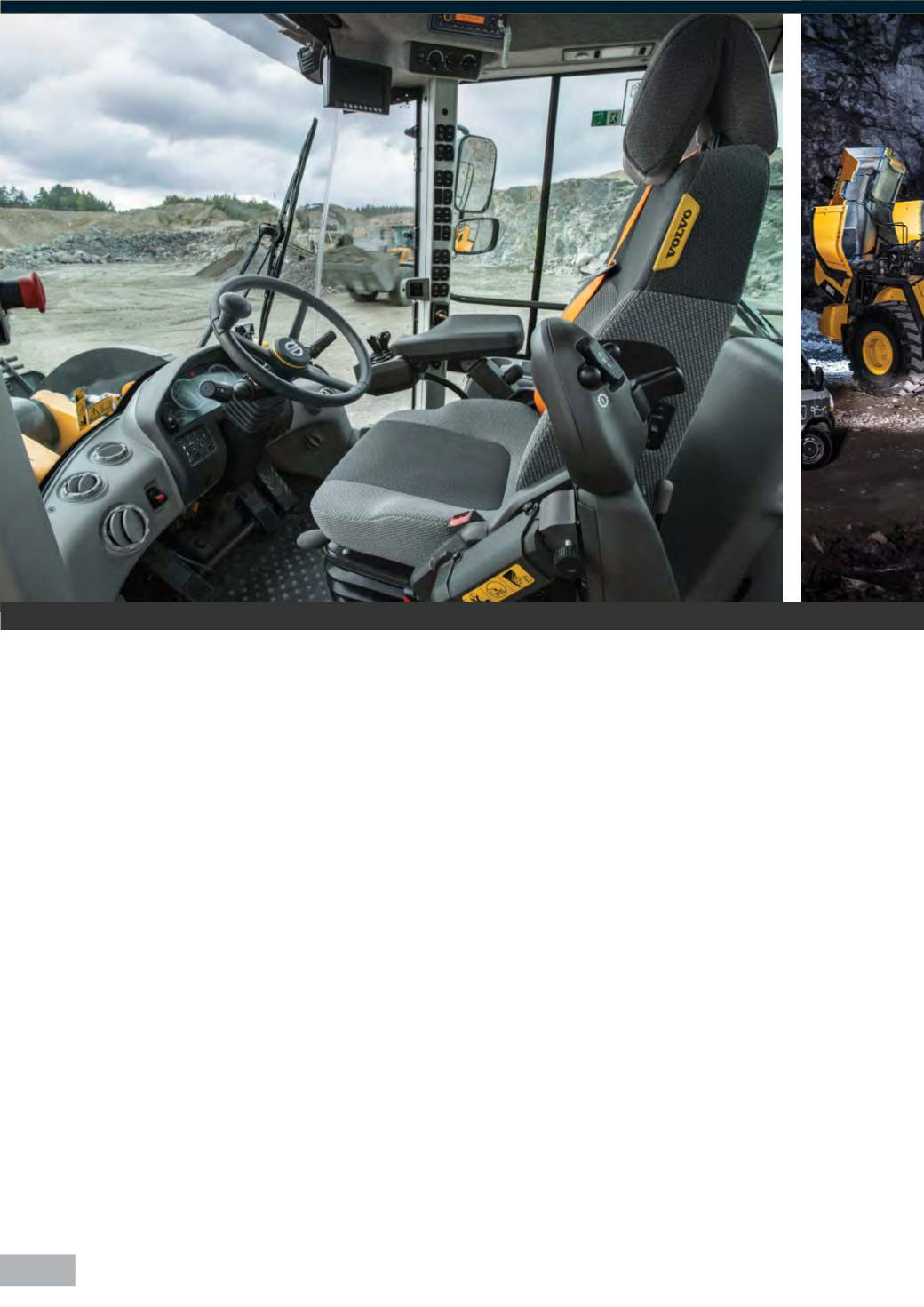

Coinciding with bauma 2016 in Munich,

Volvo CE launched no less than sixteen new

models, the plethora of which had Volvo’s

machinery designers and engineers firing

on all cylinders. And, the introduction of the

L150H, L180H and L220H series of wheel

loaders will place Volvo CE at the heart of the

construction sect or.

Innovations in this range have been closely

linked to lower life-cycle costs; low energy

consumption, ease of use and durability.

The legendary reputation of these produc-

tive, fuel efficient machines is evident in

the H-Series wheel loaders with their state-

of-the-art technology such as OptiShift – a

technological advancement which reduces

fuel consumption and increases machine

performance.

Volvo’s OptiShift technology combines the

company’s patented Reverse By Braking

(RBB) technology, with lock-up available from

first to fourth gear, to boost productivity and

efficiency in all applications. Lock-up creates

a direct drive between engine and transmis-

sion, eliminating power loss in the torque

convertor and reducing fuel consumption by

18%. RBB senses the loader’s direction and

slows the machine by applying the service

brakes automatically.

The driving force of the H-Series is the ideally

matched, all-Volvo powertrain which has

been designed to work together in harmony.

The Volvo design has been rigorously

tested to deliver optimised performance,

high productivity, low fuel consumption and

superior reliability. This long-established and

proven technology has been built by Volvo for

40 years, including all in-house components

and parts.

Power for the H-Series is the Volvo advanced

technology D13 engine, a 13 litre, six

cylinder, turbocharged unit with outputs of

between 300 kW and 373 kW depending

on the model concerned. The torque range

extends between 1 960 Nm and 2 220 Nm.

Engine regeneration is automatic and does

not interrupt operation performance or

productivity.

Productivity is key when assessing the

H-Series wheel loader range. For any

operation there is the combination of Boom

Suspension System (BSS) and attachment

selection. The optional BSS boosts

productivity by almost 20% by absorbing

shock and reducing bouncing and bucket

spillage that occurs when operating on

rough ground. This enables faster and more

comfortable work cycles and increases

machine life. Combining the right tyres, BSS

and additional counterweight, increase in

bucket size is possible, resulting in increased

productivity in rehandling applications.

VOLVO H-SERIES WHEEL LOADERS

CONTINUE THE HERITAGE

By Pierre Sanson