Controlled and resource efficient production

IN BRIEF

STRATEGY

BUSINESSES

STAKEHOLDERS

GOVERNANCE

ACCOUNTS

UPMhas certified all its European pulp and

paper mills, the UPMFray Bentos pulp mill in

Uruguay, and the UPMChangshu paper mill in

China in accordance with the EU Eco-Manage-

ment and Audit Scheme (EMAS). EMAS

requires participants to have an Environmental

Management System and to publish a third-

party verified Environmental Statement, which

increases the credibility and reliability of

environmental data. In November 2015, the EU

awarded UPM a recognition certificate for

being one of the pioneers of the 20-year-old

EMAS scheme. In order to improve energy

efficiency, UPM introduced ISO 50001 certifi-

cation systems in Germany and a national

energy efficiency system (ETJ+) in Finland.

Investments in environmental

performance

Investments ensure that UPM is able to con-

tinue its good environmental performance.

UPM’s investments in environmental perfor-

mance are part of the Group’s investment pro-

gramme and aim to improve the efficient and

responsible use of energy, water and raw

materials.

In 2015, the company’s environmental

investments totalled EUR 28 (12) million. The

single largest investment was made to waste-

water treatment and air protection at the UPM

Changshu paper mill in China.

UPM’s environmental protection costs

totalled EUR 129 (127) million, including

depreciation. The main cost items were effluent

treatment, waste management and air pollu-

tion control. Effluent treatment amounted to

Certified management systems help UPM to

control and improve the performance of the

company’s production sites in matters related

to the environment, health, safety and quality.

The company uses rawmaterials, water, energy

and other resources in a responsible manner

and continuously improves energy, production

and cost efficiency.

Almost all of UPM’s production sites, as well

as its wood sourcing operations, are covered by

environmental, quality and occupational

health and safety systems which are certified in

accordance with the ISO 9001, ISO 14001 and

OHSAS 18001 standards. Additionally, several

production sites have an ISO 22000 food safety

management system.

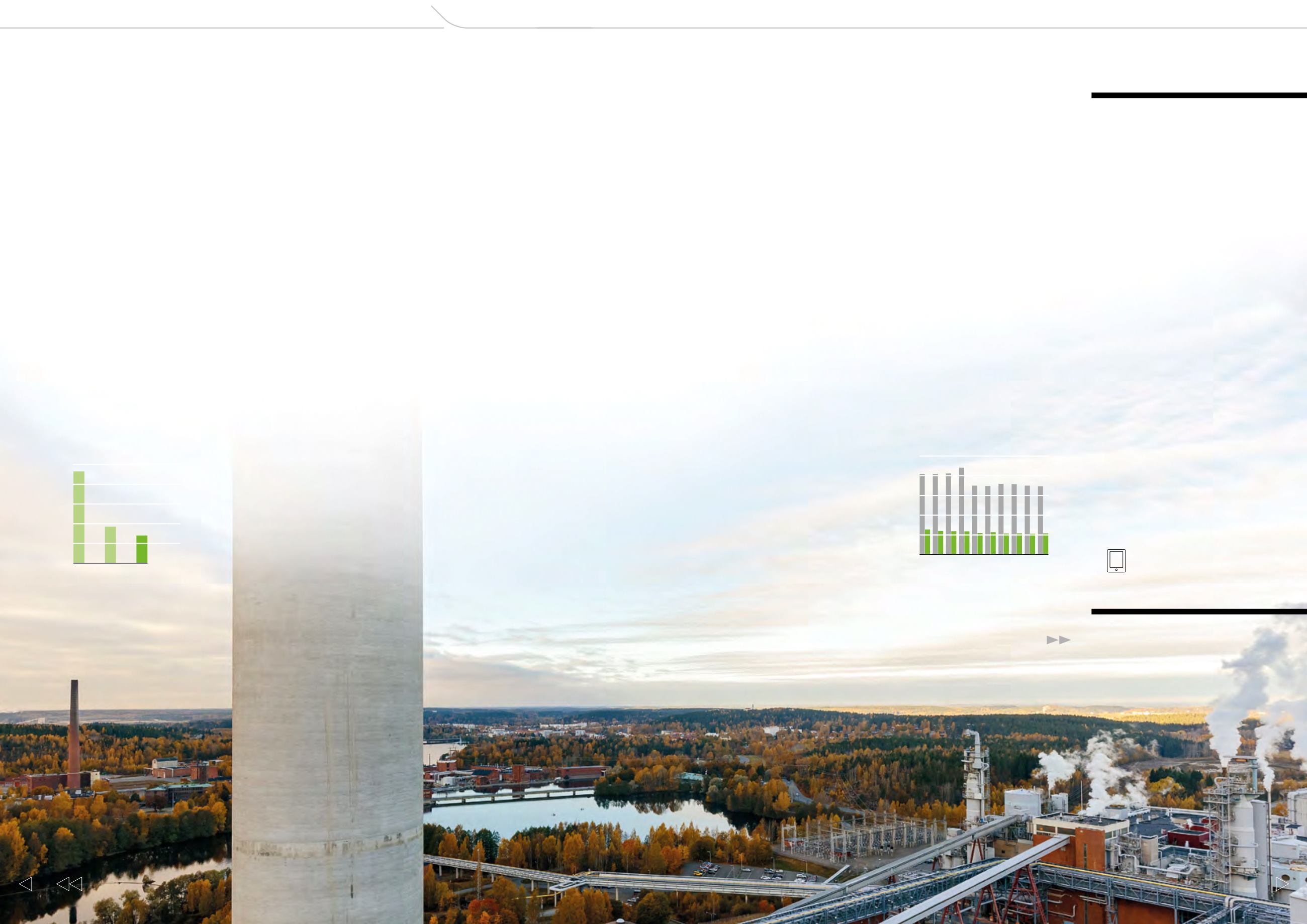

15 14 13 12 11 10 09

08 0706

50

40

30

20

10

0

■

per tonne of chemical pulp

■

per tonne of paper

UPM’s process wastewater volumes

m³/t

Water is one of the most important natural

resources and of crucial importance to UPM.

Water resources and the natural water cycle

have an essential impact on our operations in

forests, plantation forestry and the production

of energy, pulp and paper. The company’s target

is to minimise the impact of operations on local

water resources, safeguard the natural water

cycle in forests and maintain the functioning of

aquatic ecosystems.

UPM’s main production plants are located in

areas where there is sufficient water available.

The water used by UPMplants comes from

rivers, lakes or groundwater resources. UPM

uses water responsibly in terms of the com-

pany’s water consumption and effluent quality.

Reducing water consumption is a

continuous target at all UPM mills

Using less water also means using less electric-

ity, chemicals and thermal energy. The water

used in different processes is recycled as much

as possible.

All of UPM’s pulp and paper mills are

required to have both a mechanical and a bio-

logical wastewater treatment facility. In order to

ensure the best possible treatment result and

share best practice, UPM’s wastewater treat-

ment facility team has continued its work. The

results have been good and the number of inci-

dents has decreased.

UPMhas thoroughly studied the ecological

state of the effluent discharge areas at all UPM

pulp and paper mill sites using a number of

bio-indicators. The international ISO water

footprint standard, which has been in the mak-

ing for several years, was published in 2015.

UPM’s pioneering work in water footprint

research contributed to the final standard.

Hydropower plays an important role in

UPM’s versatile energy production portfolio. In

many areas, constructing hydropower facilities

has affected the reproduction opportunities of

migratory fish species. This has traditionally

been compensated by fish planting obligations

and fish management fees set by authorities.

UPM is currently participating in a two-year

project administered by the Natural Resources

Institute Finland in which suitable means for

restoring migratory fish stocks and supporting

their natural reproduction are studied.

UPMwas the first forest industry company

to sign the WASH Pledge (Water, Sanitation

and Hygiene). During 2015, access to drinking

water and sanitary conditions has been deter-

mined at all UPMproduction plants. This work

will continue in 2016.

UPMupdated its water-related targets in

2015. The previous target of reducing the COD

load by 20% by 2020 proceeded well as the

target was nearly achieved in 2015. The second

target of reducing the wastewater volume by

15% proved to be challenging. The new targets

include reducing water consumption by 30%,

reducing COD emissions by 40% and introduc-

ing the use of recycled nutrients at wastewater

treatment plants by 2030.

UPM Annual Report 2015

57

UPM Annual Report 2015

58

Water plays an increasingly important role

CONTINUOUS River

monitoring

Uruguayan environmental authorities

and UPM have conducted a continuous

monitoring of the Fray Bentos mill’s

environmental performance with the help

of several independent researchers and

environmental experts during ten years.

“Throughout the programme we have not

found any evidence that pulp mill effluents

would have an environmental impact on

water quality and biology of Río Uruguay

since the start-up of the mill in 2007,”

says biologist Jukka Tana. Tana has been

a member of the researcher group since

the very beginning of the work.

Between 2005 and 2007 the research

group concluded baseline studies of water

quality and biology of Rio Uruguay to

analyse the river as the receiving water

of the mill effluents. After the start-up

these analyses have been continued as

a permanent monitoring programme. Tana

says the monitoring programme has been

one of the most comprehensive research

works ever conducted in a pulp mill

emission studies.

“We have also recruited local fishermen to

keep a record of their fish catches. The fish

community and population structure has

remained unchanged at all three study

areas and the condition of the fish caught

has been observed to be in a good state.”

Read more:

www.upm.com/responsibility100

80

60

40

20

0

2015

2014

2013

Thanks to UPM’s internal Clean Run

environmental campaign, the number

of environmental deviations has

decreased from 2013 by 70%.

The number of environmental

deviations at UPM pulp and paper mills

EUR 49 (44) million, waste management to

EUR 34 (41) million and air pollution control

to EUR 5 (4) million. One of the focus areas in

2015 was the closer monitoring of environmen-

tal costs.

Positive development in number of

environmental non-conformances

The number of environmental non-conform-

ances has seen a significant decrease since

UPM’s internal Clean Run campaign was

launched in 2012. Almost 2,000 anticipatory

environmental observations were reported in

2015. The goal of UPM’s campaign is to further

improve the company’s environmental perfor-

mance, share best practice, and improve and

maintain environmental awareness.

No major environmental incidents

occurred at UPMproduction plants in 2015,

and UPMwas not ordered to pay any signifi-

cant fines due to non-conformances. A total of

28 (37) temporary deviations from permit

limits or major deviations from the environ-

mental limits set by UPM occurred at the

company’s pulp and paper mills during the

year. The most notable deviations were either

small oil leaks to nearby waters or biological

sludge losses fromwastewater treatment

plants. UPM immediately reported deviations

from permit limits to the local authorities and

undertook corrective measures to normalise

the situation and prevent similar situations

from occurring in the future.

UPM has reduced wastewater volumes

per tonne of paper by 16% and per

tonne of chemical pulp by 16% over

the last ten years.

contents