CAPITAL EQUIPMENT NEWS

JULY 2016

15

EQUIPMENT REBUILDS

A

ccording to Andrew Yorke, operations

director of Metric Automotive Engi-

neering, major engine failures occur

as a result of poor maintenance practices,

and adopting a sound preventative mainte-

nance regime will save fleet owners signifi-

cant direct and indirect costs.

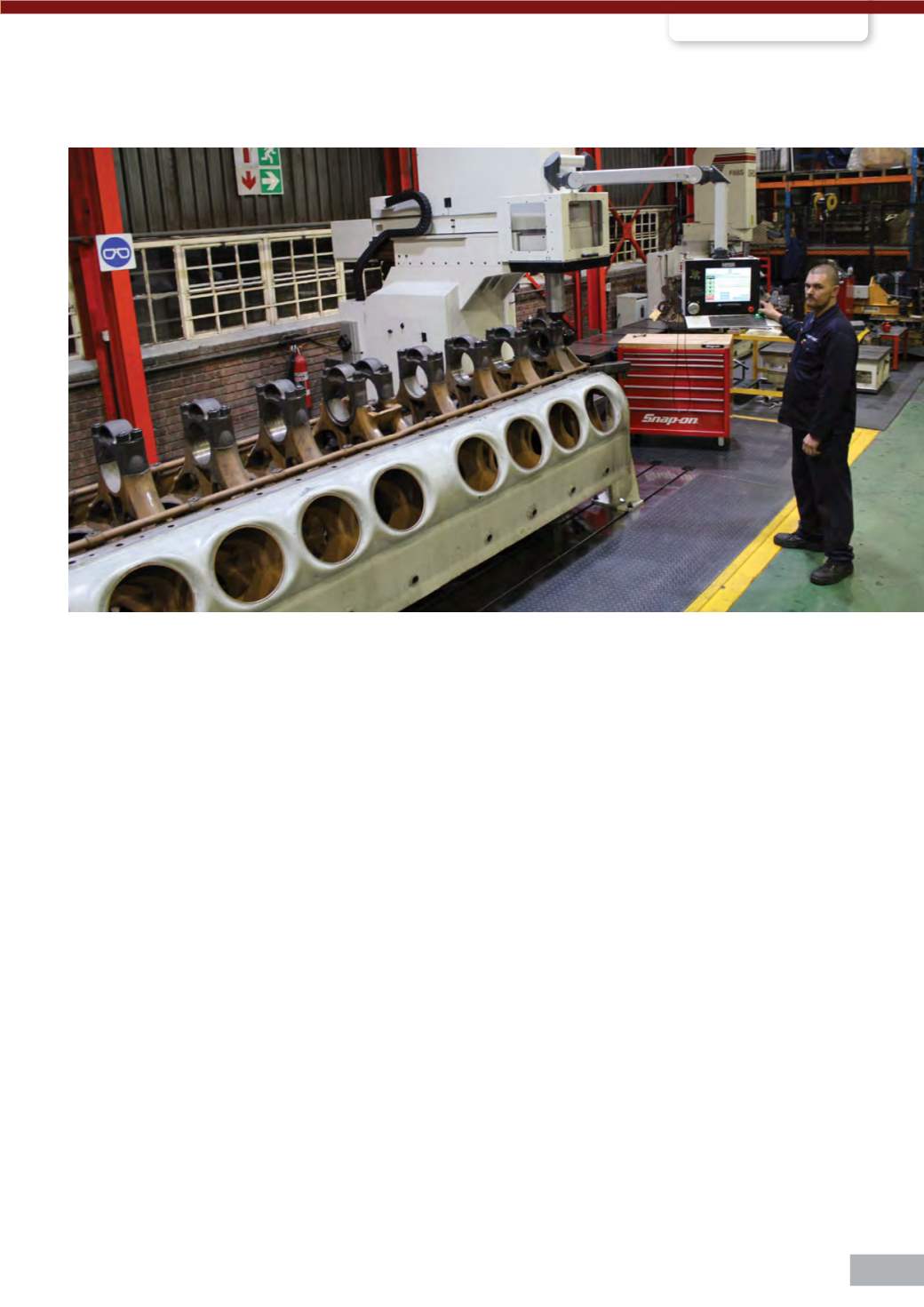

Metric Automotive Engineering is well

known in the earthworks, mining and quar-

rying industries for its ability to remanufac-

ture diesel engine components to original

equipment manufacturers’ (OEM) specifi-

cations, and even exceed these standards.

Yorke is concerned that many fleet opera-

tors are cutting down on their maintenance

programmes in these challenging economic

conditions. He warns that this practice will

inevitably lead to catastrophic engine fail-

ures on costly equipment in industries that

simply cannot afford unwanted downtime

and unnecessary costs. This is especially

likely in the African context where contam-

inated and diluted diesel can cause major

damage to new, sophisticated engine tech-

nologies.

“In addition to poor combustion and an

increase in diesel burn, long term issues

that can arise from ongoing exposure to

inferior quality diesel include fuel dilution

and premature component wear problems,

ultimately leading to a catastrophic engine

failure,” he warns.

Yorke says that one of the critical bene-

fits of implementing a sound preventative

maintenance programme is that it allows

fleet owners to manage and prevent an un-

scheduled failure. Corrective intervention

can be implemented timeously to eliminate

the large costs associated with repairing a

failed engine and the expensive price tag

attached to downtime on a mine, quarry or

construction site.

Yorke says other drastic measures are be-

ing taken by fleet operators to cut costs

and these are also compromising their

remanufacturing programmes. In some in-

stances, remanufactured engine dyno tests

are being neglected despite the significant

investment into remanufacturing engine

components. These tests ensure that the

vital performance specifications of the re-

manufactured engine have been achieved

to ensure a full service life performance.

He encourages fleet operators to analyse oil

samples regularly as this can help to iden-

tify issues such as coolant contamination

and other factors that lead to high wear on

engines and components.

One of Metric Automotive Engineering’s

heavy industrial customers has never ex-

perienced a catastrophic engine failure

because of its stringent preventative main-

tenance strategies, which involve weekly oil

sample analysis practices to identify exactly

where fatigue is occurring. Importantly, it

also reveals trends and patterns that allow

this customer to schedule repair services to

avoid catastrophic engine failures.

Yorke believes that most of the pitfalls in

preventative maintenance can be attributed

to the limited role that technical depart-

ments now play in choosing best practices

to keep fleets operating at optimal levels.

This important function has increasingly

been delegated to purchasing departments.

As he points out, sound maintenance de-

cisions can only be based on a thorough

understanding of the complexities of the

various components, including a quality re-

manufacturing operation.

There is a reason why all of Metric Au-

tomotive Engineering’s customers keep

returning. The company has saved them

exorbitant costs, while keeping tonnages

moving.

b

METRIC AUTOMOTIVE ENGINEERING

prevents catastrophic failures

The cylinder block machining centre at Metric Automotive Engineering.