3 4

T H E M A G A Z I N E F O R T H E U K O F F S H O R E O I L A N D G A S I N D U S T R Y

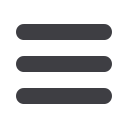

He explains: “Flow meters are the

industry’s cash registers and they

need to be accurate. Without them, it

is impossible to ensure standardised

volumes or mass quantities for trade or

sale. This would impact the financial

operations of a company through

inconsistent cash flows for produced

fluids. Additionally, without flow

measurement it would be impossible to

optimise operations.

Muir points out that enhancing UK

capability in this area is of “particular

skills development, research

and testing facilities,

a community of

expertise, and

a focus on

leadership.

Going

forward,

NEL wants

to facilitate

greater

collaboration

within the flow

measurement

community.”

In late 2014, NEL,

along with Coventry

University, founded the Flow

Measurement Institute. With now

over 20 members among operators,

manufacturers, academia, the regulator

and service companies, it responds

to Sir Ian Wood’s report by driving

a collaborative approach to meet the

importance in the current economic

climate and with increasing subsea

processing and deeper field extraction

at higher pressures and temperatures”.

He says: “There is a need now and in

the future for flow meter calibration at

elevated pressures and temperatures.

These are the parameters with the

greatest impact on meter performance.

A potential impact running into many

millions of pounds per annum for a

single well is common.”

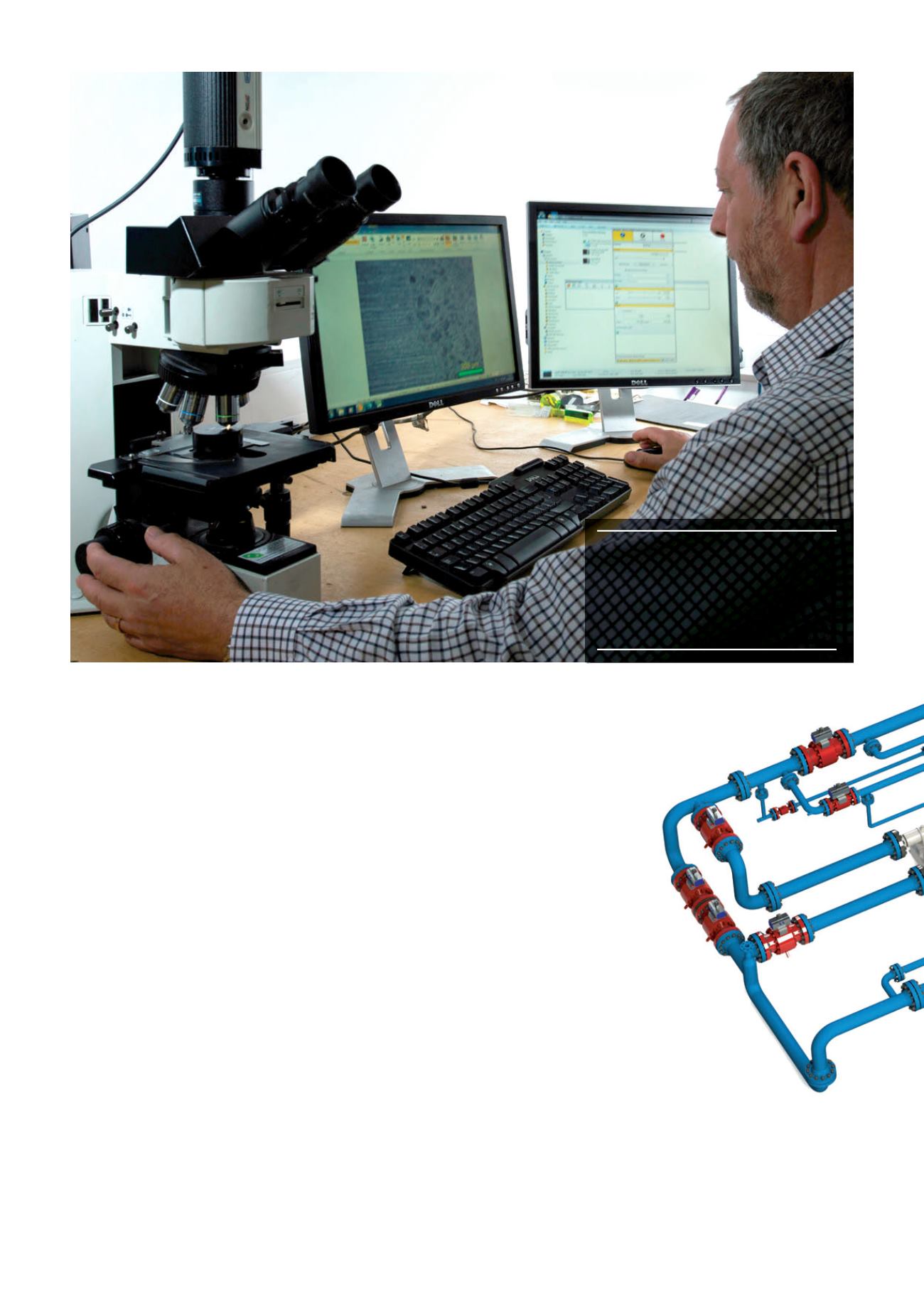

NEL’s new high pressure/high

operating temperature liquid flow test

loop increases the company’s pressure

testing capability from below 10 bar(g)

to 100 bar(g), with an ability to deal

with temperatures doubling from

40 degrees Celsius maximum capability

to 80 degrees Celsius.

The new facility will also carry out

R&D into flow and fluid measurement.

Muir adds: “Developments and

investment will be industry-led for

maximum impact. As part of the

Flow Measurement Institute, we will

help lead the creation of a tangible

centre of excellence that includes

“

The centre not

only represents ongoing

investment in the

subsea sector but our

commitment to ensuring

that we are at the

forefront of technological

advancement.

”

Knowledge and data from testing

operations at GE Oil & Gas’ Newcastle

Innovation Centre is used to develop

and validate new and existing models,

predicting the performance of flexible

pipes in service