CVPDC-0914

TECHNICAL AND PERFORMANCE DATA

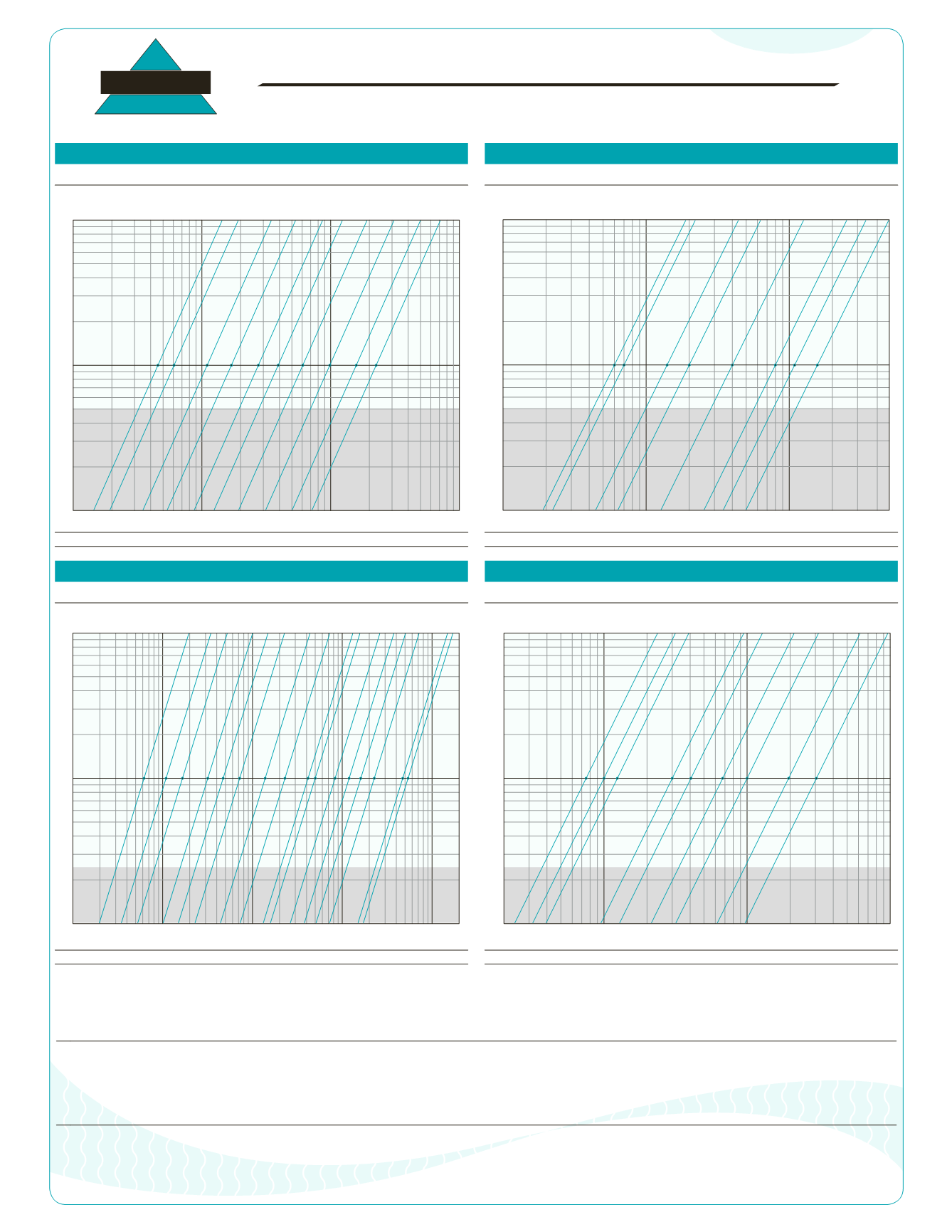

PRESSURE DROP CHARTS

f

CHECK VALVES

TITAN

TITAN FLOW CONTROL, INC.

Style: Threaded Ends, Silent CheckValve

Style: Threaded Ends, Silent CheckValve

Model: CV 20-BZ (Bronze Unit)

Model: CV 80-SS (Stainless Steel Unit)

Legend: Pressure Drop - PSI (y - axis) versus Flow Rate - GPM (x - axis)

Legend: Pressure Drop - PSI (y - axis) versus Flow Rate - GPM (x - axis)

Style: WaferType, Single Disc CheckValve

Style: WaferType, Short Pattern, Swing CheckValve

Models: CV 31-DI, CV 32-CS/SS

Models: CV 12-CS/SS

Legend: Pressure Drop - PSI (y - axis) versus Flow Rate - GPM (x - axis)

Legend: Pressure Drop - PSI (y - axis) versus Flow Rate - GPM (x - axis)

Pressure Drop Equation for Liquids:

Δ P = G × (Q / Cv)

2

Δ P = Pressure drop (psi)

G = Specific gravity of liquid at 60 °F

Cv = Flow coefficient factor

Q = Flow rate (GPM)

0.2

0.3

0.4

0.5

0.7

1

2

3

4

5

6

7

10

1

0.1

2 3 4 5 6 7 8 10

20 30 40 50 70 100

200 300 500 700 1000

3/8

1/4

1/2

3/4

1

1 1/4

1 1/2

2

2 1/2

3

4

Sizes (in):

C v

C v

5

6

11

17

27

39

61

98

158

225

Valve Cracking Pressure (0.5 psi)

(Horizontal Position)

0.2

0.3

0.4

0.5

0.7

1

2

3

4

5

6

7

10

1

0.1

2 3 4 5 6 7 8 10

20 30 40 50 70 100

200 300 400 500

3/8

1/2

3/4

1

1 1/4

1 1/2

2 1/2

3

2

C v

C v

6

7

14

20

40

80

110

162

Sizes (in):

Valve Cracking Pressure (0.5 psi)

(Horizontal Position)

0.2

0.3

0.4

0.5

0.7

1

2

3

4

5

6

7

10

10

0.1

20 30 50 70 100 200 300 500 1000 2M 5M 10M 20M 50M 100M 200M

Sizes (in):

C v

C v

62

109

166

318

471

720

1384

2298

4153

4984

8307

11906

16059

22705

47071

53993

2

2 1/2

3

4

5

6

8

10

12

14

16

18

20

24

30

36

Valve Cracking Pressure (0.25 psi)

(Horizontal Position)

30 40 50 70 100

200 300 500 700 1000

2M 3M 5M 7M 10M

20

0.1

0.2

0.3

0.4

0.5

0.7

1

2

3

4

5

6

7

10

C v

C v

75

100

124

300

405

675

1000

1950

3050

2

2 1/2

3

4

5

6

8

10

12

Sizes (in):

Valve Cracking Pressure (0.25 psi)

(Horizontal Position)

Tel: 910-735-0000

s

Fax: 910-738-3848

s

titan@titanfci.coms

www.titanfci.com290 Corporate Drive

s

PO Box 7408

s

Lumberton, NC 28358

TITAN FLOW CONTROL, INC.

•

These curves are theoretical; actual results may vary depending on installation conditions and other variables. Use these values for reference only.

•

The above pressure drop charts are based upon 1/8" perforated screens and baskets handling clean water at 60 °F during ideal inlet and outlet conditions. Therefore, they

should only be used for estimation purposes.

•

For fluids other than water, multiply the pressure drop (Δ P) obtained from the charts by the specific gravity of the fluid in question.

•

For mesh lined screens, multiply the pressure drop (Δ P) obtained from the charts by the corresponding correction factor shown in the Cv correction table.