have

titan

professionally

install

a

bv

24

or

bv

25

when

purchasing

a

titan

y

-

strainer

.

not

only will

you

be

assured

that

it

is

installed

correctly

,

but

you

may

save

on

shipping

costs

as well

.

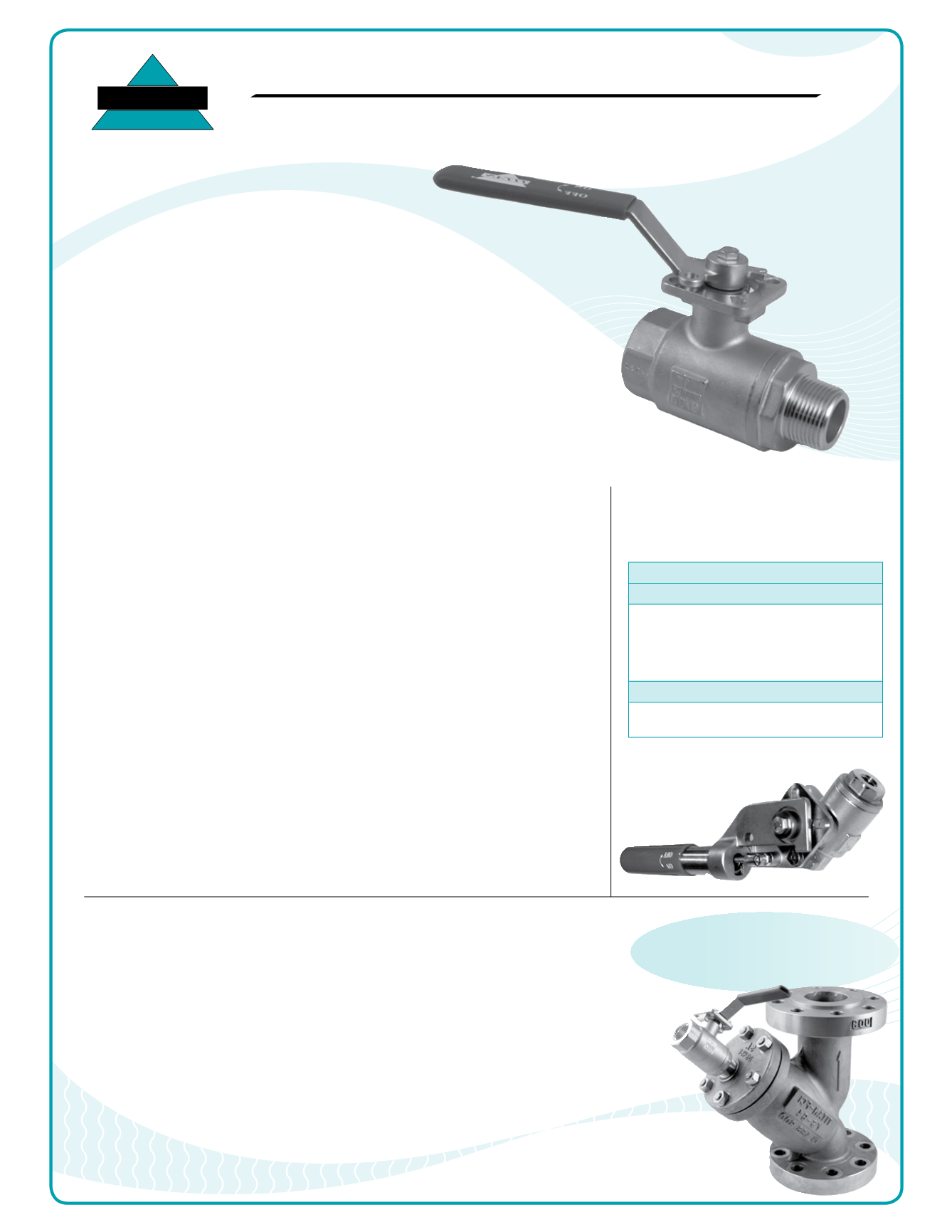

BLOW-OFF DRAIN VALVE

f

HIGH PRESSURE BALL VALVE

3000WOG

f

STAINLESS STEEL

f

TWO PIECE DESIGN

BV2425-0609

s

ful l

port

de s i gn

of f e r s

comp l e t e

and

rap i d

cl ean i ng

of

s tra i ne r

scr e en

;

s i ze

2

"

i s

r educed

port

s

i deal

b low

-

of f

valv e

for

h i gh

p r e s sur e

s tra i ne r s

ans i

cla s s

600

,

900

,

and

1500

s

d i r ect

mount

actuat i on

-

me e t s

i so

5211

s

op t i onal

s a f e ty

"

dead

-

man

"

,

s p r i ng

r e turn

handl e

i s

ava i lab l e

s

lock i ng

handl e

wi th

qu i ck

quart e r

turn

op e rat i on

s

mal e

thr ead

ends

mount

d i r ect ly

i nto

s tra i ne r

b low

-

of f

connect i on

s

p rof e s s i onal ly

i ns tal l ed

at

our

factory

ensur e s

qual i ty

and

he l p s

to

r educe

sh i p p i ng

and

labor

cos t s

MODELS:

BV 24

(3000WOG - Female x Female)

BV 25

(3000WOG - Male x Female)

1 / 4

"

through

2

"

T

TECHNICAL

PRESSURE/ TEMPERATURE RATING

BODY: CF8M STAINLESS STEEL

WOG

(Non-shock)

: 3000 PSI @ 100 °F

MAX LIQUID: 80 PSI @ 400 °F

MAX STEAM: 150 PSI @ 366 °F

BALL SEAT: DELRIN

TEMPERATURE: -20 °F ~ 180 °F

TITAN

TITAN FLOW CONTROL, INC.

F

FEATURES

Tel: 910-735-0000

s

Fax: 910-738-3848

s

titan@titanfci.coms

www.titanfci.com290 Corporate Drive

s

PO Box 7408

s

Lumberton, NC 28358

TITAN FLOW CONTROL, INC.

A

APPLICATIONS

SCREEN CLEANING:

during

normal

use

,

the

strainer

screen

will

become

clogged

with

foreign

matter

causing

the

differential

pressure

to

increase

.

once

the

differential

pressure

has

reached

an

unacceptable

value

,

blow

-

down

cleaning

is

recommended

.

it

is

not

advisable

to

allow

the

differential

pressure

to

increase

by

20

psi

as

this

may

cause

the

screen

to

fail

and

possibly

damage

downstream

equipment

.

if

the

differential

pressure

is

not

restored

to

normal

parameters

after

blow

-

down

cleaning

then

the

screen

must

be

removed

and

cleaned

or

replaced

.

shown

with

optional

spring

-

return

handle

YOUR PIPELINE TO THE FUTURE!

self

-

cleaning

y

-

strainer