MERCURY – TIME TO ACT

34

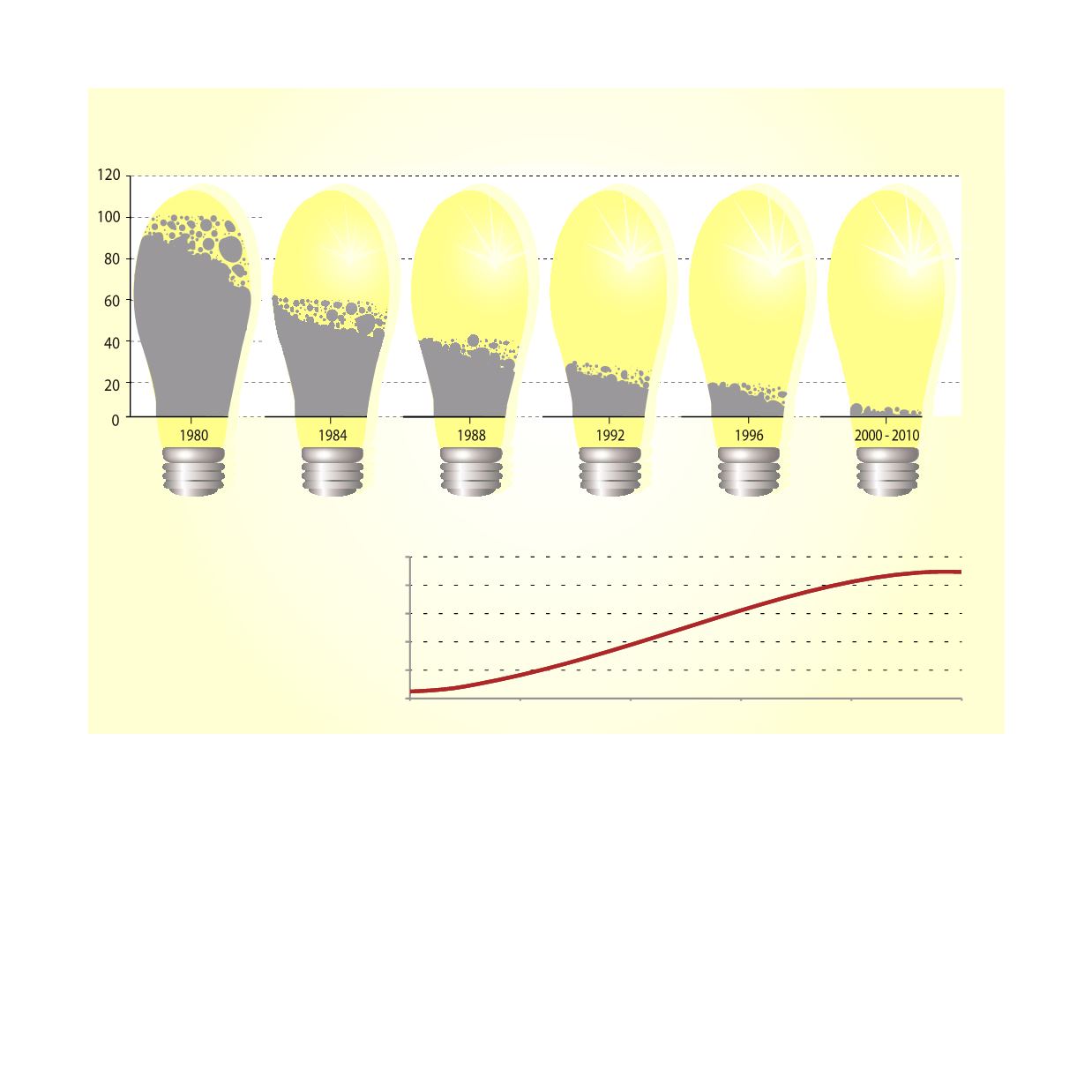

Compact uorescent lamps (CFLs)

Level of mercury per bulb (mg)

Source:

Adopted from European Lamp Companies Federation

→http://www.elcfed.orgUNEP en.lighten, December 2012

Designed by Zoï Environment Network / GRID-Arendal

Global Sales of CFLs (millions)

1,000

2,000

3,000

4,000

5,000

Global CFL Sales

1995

2000

2005

2010

2015

2020

Managing surplus mercury involves collection, stabilization

and safe disposal to isolate it from the biosphere. Stabilizing

mercury offers several benefits: technology is available on an

industrial scale, there is no risk of liquid spillage, vapour pres-

sure is below occupational safety limits, and mercury con-

centrations in leachates are below the threshold for disposal.

Beyond that, the lower commercial value of the stabilized

mercury reduces the risk of theft, and disposal after stabiliza-

tion by binding with sulphur is possible. Several stabilization

technologies exist: chemical transformation into a more sta-

ble, less mobile chemical compound; micro-encapsulation,

the embedding of particles in an impermeable matrix such

as cement; and macro-encapsulation, the covering of waste

material with an impermeable material, for example poly-

ethylene. The fact that stabilized mercury is non-toxic signifi-

cantly helps the search for suitable storage sites. Unlike liquid

mercury, the stabilized form is suitable for storage in landfills

and underground.