9

5.1 Primary Inertia (mass)

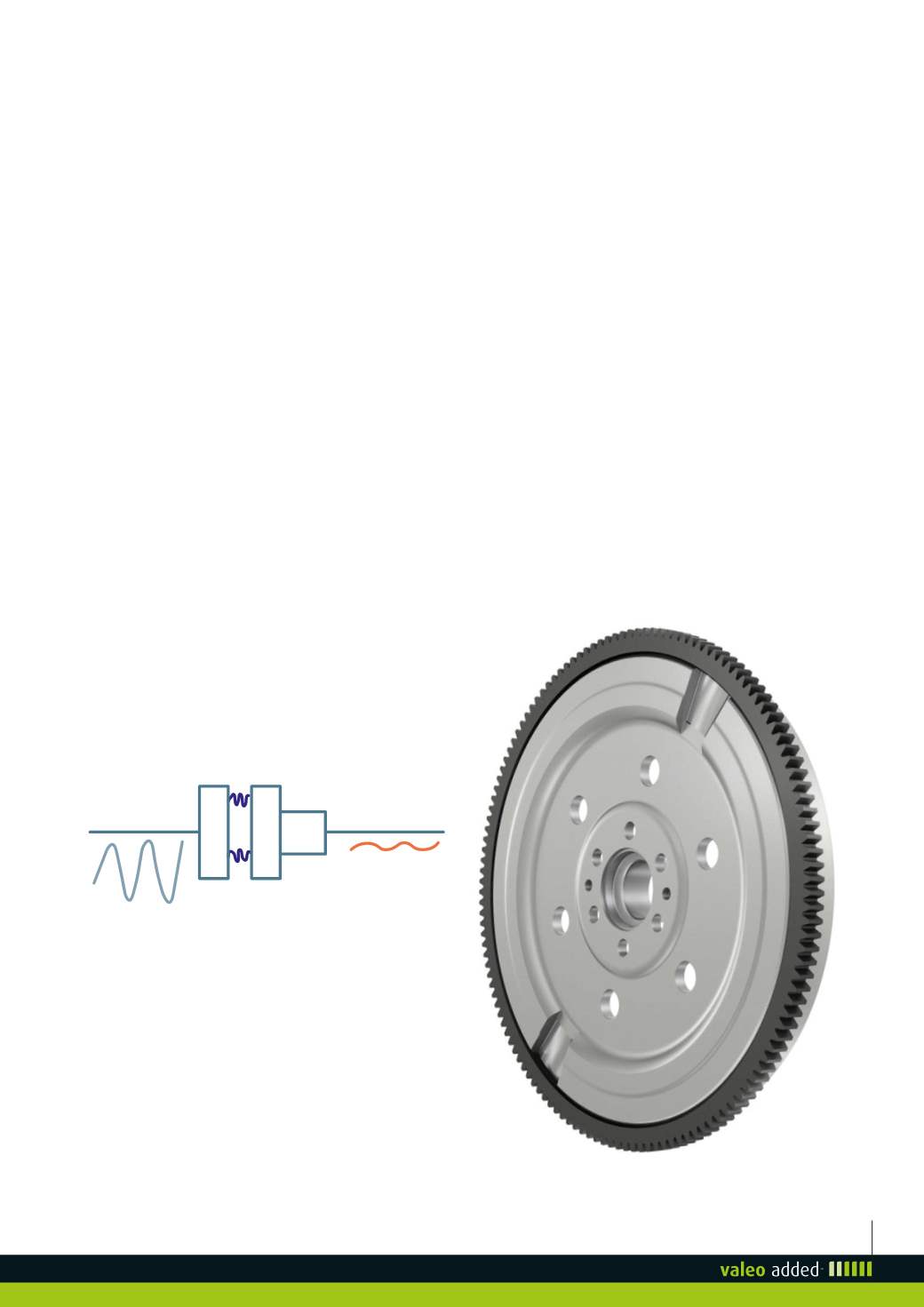

Primary Flywheel

The primary flywheel is bolted to the engine

crankshaft. It is a steel stamped component with a

sufficient mass moment of inertia. In certain cases,

it could be made of cast iron. The ring gear is press

fitted on the flywheel to interface with the engine

starter.

The primary flywheel is bolted directly to the

crankshaft and contains the damping springs. The

secondary flywheel is fitted with a conventional

clutch cover and solid disc with a lower inertia,

improving the gear shifting.

There are two long curved springs between the

flywheels that absorb the engine vibrations. The

main advantage is a greater angular damping which

allows the maximum filtration.

A cover plate is welded to the primary flywheel

to form a chamber filled with low-friction grease

to help the springs move freely. The secondary

flywheel is made of special cast iron that can resist

the high thermal loads of the clutch.

Engine

Gearbox

DUAL MASS FLYWHEEL

Primary flywheel

Secondary flywheel

Clutch kit