8

Wire & Cable ASIA – May/June 2014

www.read-wca.comIndustry

news

SeAH Wheelabrator upgrade

❍

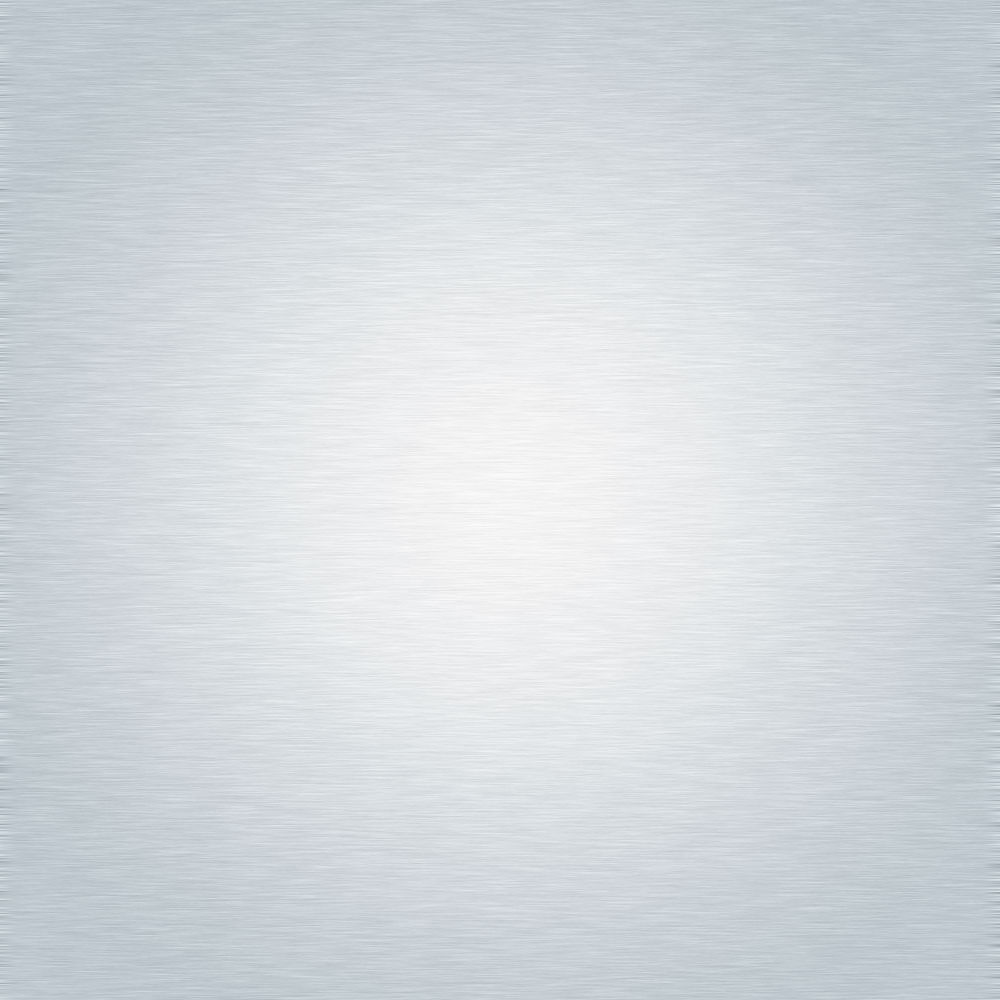

Wire descaling machine at SeAH Special Steel

Graphics bigstockphoto.com Artist Eky Studio

SeAH Special Steel Co Ltd, a

manufacturer of special steels, is

upgrading its operations in Pohang,

Korea, with nine wire descaling

machines from Wheelabrator.

The new equipment will be delivered

throughout the year and will replace

existing shot blast machines from

various European and Asian OEMs.

The single strand shot blast machines

from Wheelabrator reliably remove

scale, rust and other contaminants

from the wire or rod surface before

processing, and can be integrated into

existing fully automated drawing lines.

Depending on production requirements,

machines with three, four or six blast

wheels, arranged along the longitudinal

axis of the wire or rod, are available and

ensure consistent and even coverage.

Guide plates focus the abrasive stream

onto the wire surface, thereby boosting

the descaling effect without increasing

abrasive throughput. This improves the

efficiency of the whole blasting

process.

Wire descaling machines from

Wheelabrator allow drawing speeds of

up to 240m/min, matching those in

modern drawing lines.

Viktor Lussi, sales director at the

Wheelabrator

Technology

Centre

Zürich (DISA Industrie AG), said: “The

customer wanted to upgrade their

operations to meet highest standards

of quality and reliability.

“SeAH Special Steel already had

several Wheelabrator machines in

operation and were very happy with its

proven track-record for quality and

productivity. This new order just goes

to show that, when it comes to

integrated production environments,

investment in highly reliable equipment

pays off.”

Beyond wire descaling equipment,

Wheelabrator also offers single or

multi-strand blast machines for steel

rod and wire coil, which can be

adapted to suit individual customers’

requirements. For example, machines

can be supplied for stand-alone

operations with separate handling or,

as the example SeAH showed, as an

integrated solution.

Wheelabrator Technology Centre

Zürich – Switzerland

Website

:

www.wheelbratorgroup.com