The evolution of trolley

wire

manufacturing

▲

▲

Innovation and technology from Cortinovis Sictra

Corporatenews

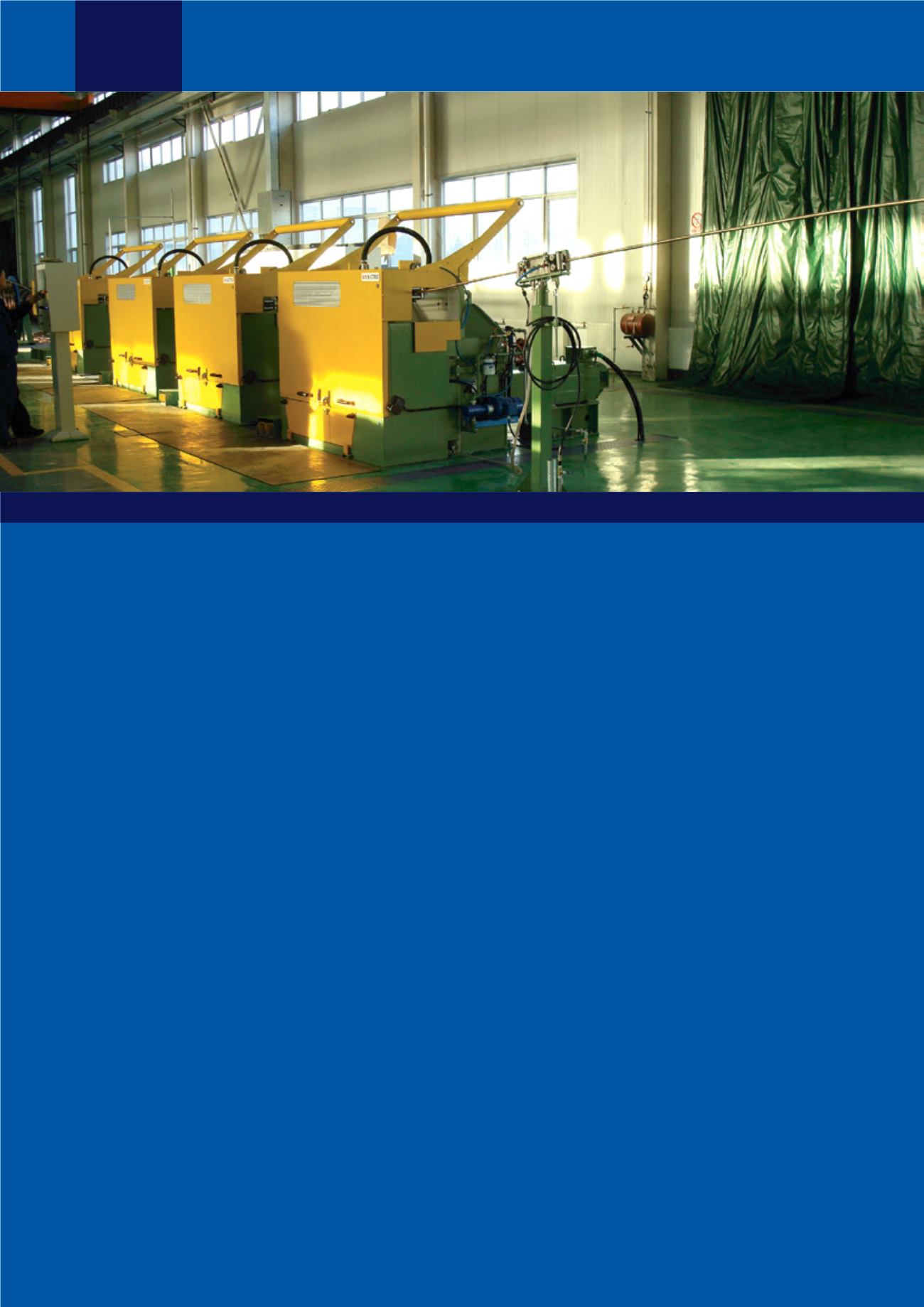

Among wire and cable machinery

suppliers, Cortinovis and Sictra are

recognised for the advanced technology

of their products and equipment

reliability.

Many users with machinery from decades

ago are still using their equipment,

counting on the continuous supply of

original spare parts from Cortinovis Sictra

when they are needed.

It was at the beginning of the 1980s

when Sictra developed its first integrated

drawing line for shaped trolley wires, and

the development of high-speed railways

was still to come.

At that time, it was common practice to

draw the shaped trolley wires utilising a

single deck bull block, with which the rod

was drawn down with several subsequent

passages until the shaped wire final cross

section was achieved.

The design and construction from Sictra

of an integrated drawing line with

four capstans represented a dramatic

improvement.

Productivity

increased

by a factor of ten while manpower

requirement reduced. Not only that,

but the scrap rate was also reduced

significantly and the quality of the final

product enhanced.

It soon became evident to the Industry that

competing in the manufacture of trolley

wires was no longer possible unless the

equipment in use was up to date.

The product itself was subject to a

significant evolution. The drives of this

development have been environmental

protection on one side and the increase

of operation speed of the railways on the

other side.

For a long time, copper was utilised for

trolley wire alloyed with cadmium. The

presence of cadmium gives to copper

a much higher resistance to softening

at elevated temperatures and also to

arc erosion, as extremely heat resistant

cadmium oxide forms on the surface of

the wire during arcing and protects it

from eroding.

Cadmium, however, is very toxic, even

more than lead or mercury, therefore it

has been replaced for this application by

other metals to be alloyed with copper.

Nowadays the most utilised copper alloys

for high-speed trains granting operating

speed up to 400km/hour are copper and

magnesium alloys; wear and tear is the

lowest, while breaking load the highest.

Silver copper and tin copper alloys are

also used.

All of this implied a redesign of the Sictra

trolley wire integrated drawing line.

A modern line capable of drawing Cu Mg

0.5 alloy is usually made of four capstans,

the first two with 1,200mm diameter and

the last two with 1,000mm diameter.

The AC motors provide adequate torque

to the capstans to match the higher rod

tensile strength of the new alloys and

the increased breaking load of the final

product.

More often the line is designed with five

capstans (2 x 1,200mm and 3 x 1,000mm)

to be able to draw down copper alloy rod

with inlet diameter up to 30mm.

The process and the increased powers

involved in it require an efficient capstan

cooling system via inside chilled water

circulation and rotating joints. Wire

lubrication and additional cooling is

provided with emulsion spray on the

capstans’ surface and most efficient

lubrication of the round and shaped dies

is achieved with specific oil circulation

and die holders’ chilled water cooling. All

of this requires three separate cooling and

circulating circuits.

Cortinovis Sictra – Italy

Website

:

www.trafcomachinery.com www.read-eurowire.comMarch 2015

10