V

OL

24 N

O

6

N

OVEMBER

/D

ECEMBER

2011

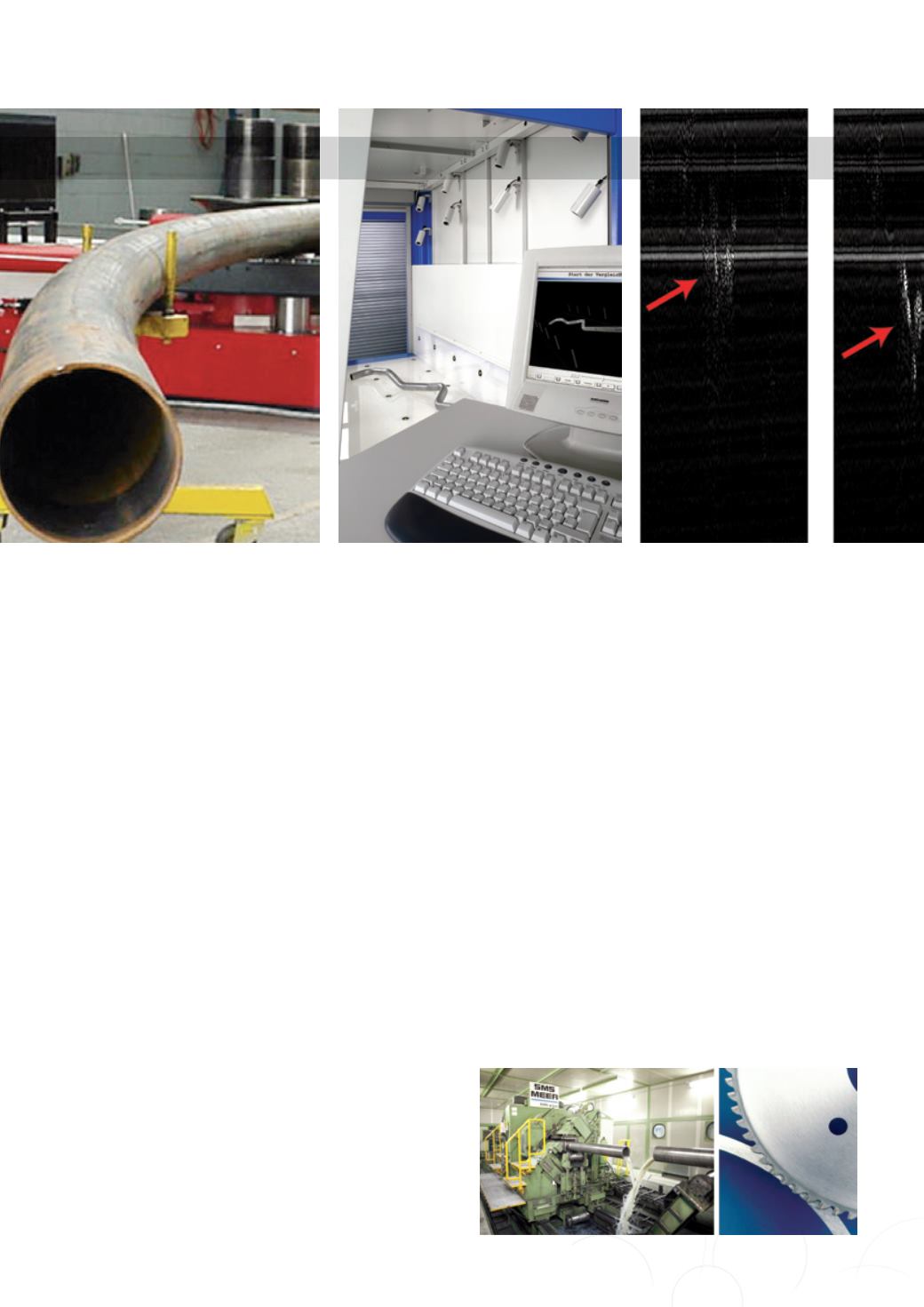

Bending

Manipulation of a length of

tubing of various sizes entails

vulnerability: to breakage, wrinkling,

scratching, marking, humping,

collapse, excessive springback,

and link failure, among others.

The methods by which these

threats are circumvented may vary,

but never the results. The sole

standard applicable to the finished

workpiece is always “bent the best

way.” The companies on these

pages are some of the best in the

world at this difficult task.

Software

The expression “human-machine

interface” was once spoken

with awe, as the direction and

management of a production

run of tube and pipe were being

moved from the plant floor to a

room with windows, high above

the action. Now, that interface

is taken so much for granted as

to have fallen out of the working

vocabulary – the universal sign of

a rousing success and a vital part

of the industry in terms of helping

to improve efficiency.

Special feature

This special feature looks at a

bronze alloy pipe that was part of

a pump assembly that appeared to

be leaking at numerous locations,

but close visual inspection

found no cracks. An acoustic

microscope revealed not only

the cracks but also their unusual

arrangement. The pipe was filled

with water under pressure and

observed for leaks. Water soon

appeared on the outer surface of

the pipe, but it could not be traced

to a single leakage point.

78

88

92

CONTENTS

99

Experiences gathered in the operation

of the 12¾" tube welding plant

By Frank Lagac, SMS-Meer GmbH and M Caldonazzo,

Arvedi Tubi Acciaio SpA