CONSTRUCTION WORLD

JULY

2017

46

EQUIPMENT

Thanks to Furukawa’s unique Monoblock

construction with no through-bolts, as well

as less moving and wear points, these

tough breakers can last for years in the

hardest labour conditions. In addition,

the lighter weight and harder hitting power

of the Monoblock system means that

smaller breakers are required to do the

same work as bulkier counterparts from

other manufacturers.

“The power-to-weight ratio of the

Furukawa FXJ-range has a hammer weight

to joules output that is unmatched in

the industry (Construction and Industrial

Manufacturers Association rated tests). For

the contractor, this means saving money

on operating costs, diesel and in many

instances, it frees-up larger excavators for

production work.

“Our breakers also transfer less shock to

the excavator due to larger slip-buffer plates

that eliminate impact recoil shock on the

excavator’s boom,” says national product

manager, James Linton of ELB Equipment,

the exclusive distributor of Furukawa rock

breakers in Southern Africa. “That means

the Furukawa design is far more robust and

reliable with considerably less maintenance

required, as well as being smaller and less of

a burden on the excavator.“

ELB Equipment has a comprehensive

range of Furukawa Rock Breakers and

attachments for almost any application.

In addition, the company has the highly

convenient F6-BHL breaker that has been

specially designed for use on backhoe

loaders (TLBs) to provide solutions in

construction type environments, road

building, demolitions etc.

“In today’s tough market it is important

that contractors realise that a rock breaker

need not only last the duration of a contract

and then be discarded. This has misguided

some to settle for cheap hammers that

cost 20% less, but at the same time give

them 40% less availability. Furukawa’s, by

comparison, have been running on many of

our customer’s sites for more than 10 years

and will work all day every day.

“They are also comprehensively

supported through ELB Equipment’s dealer

network that extends across southern

Africa. Why buy breakers that are built to

last the duration of just one contract when

you can buy a Furukawa and complete many

more,” concludes Linton.

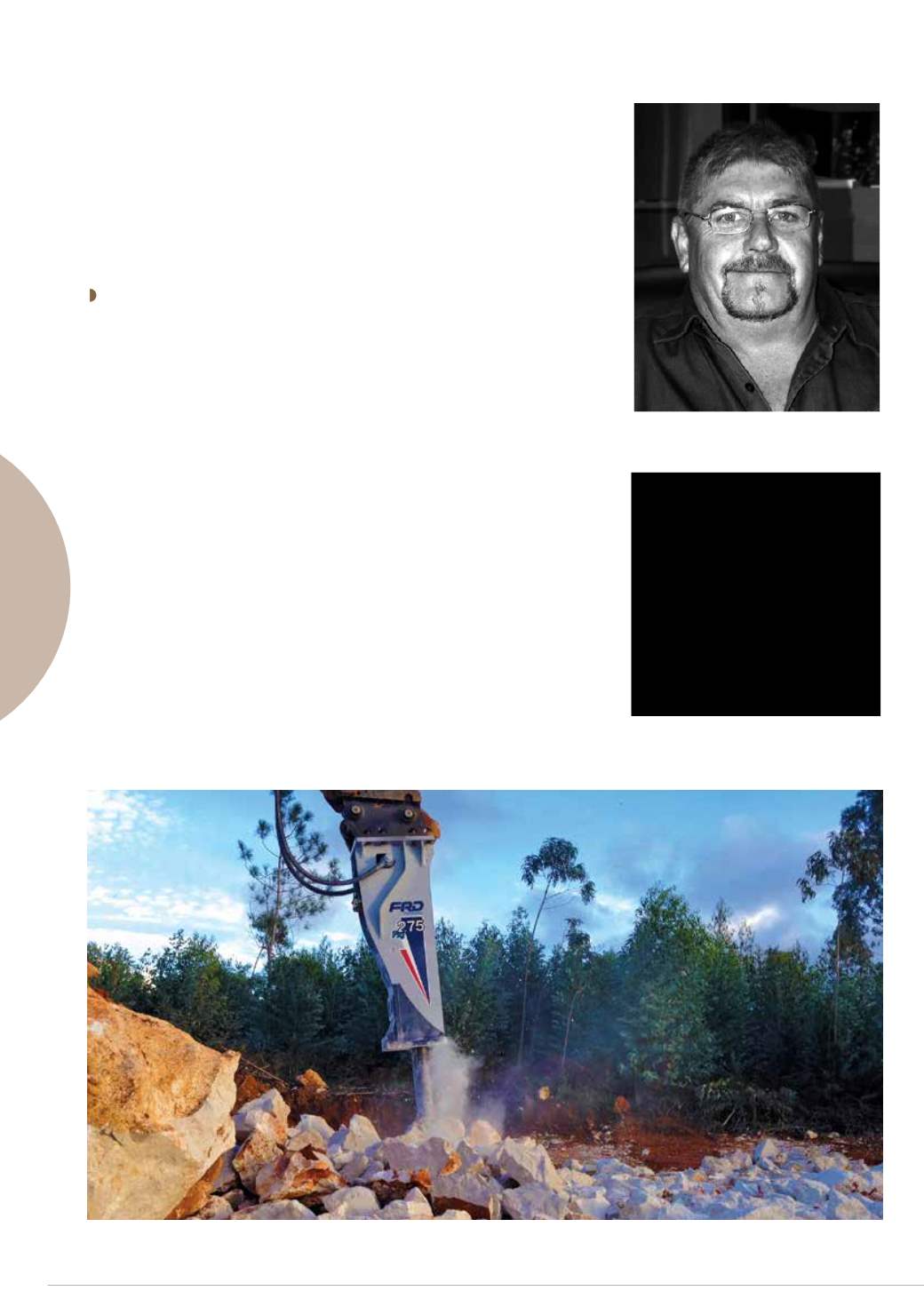

REAL HARD LABOUR

Excavator-mounted rock breakers from Furukawa are proving to be

extra-durable in the field which is driving contractors to reexamine their

long-held belief that rock hammers be regarded as ‘consumables’ with

only a relatively short life span.

BELOW:

FXJ 275 rock breaker from Furukawa.

Furukawa Rock Breakers are designed

for use in a wide range of applications

including plant hire, high productivity

mining applications, demolitions, as

well as primary and secondary rock

breaking applications.

The Furukawa range includes:

• Excavator-mounted hydraulic breakers

• Backhoe Loader-mounted hydraulic

breakers

• Combination cutter crushers for

demolition

• Lifting grabs

• Excavator mounted compactors.

James Linton of ELB Equipment.