CAPITAL EQUIPMENT NEWS

AUGUST 2017

18

T

here is considerable rise in popularity

of mobile crushing solutions in the

African marketplace, primarily due

to the versatility and mobility many users

of this gear require, notably crushing

contractors. But, as mobility and versatility

alone may not be sufficient to offer

profitable solutions, fuel savings and

energy efficiency have also become major

factors in influencing buying decisions.

To offer customers the flexibility to

operate fully mobile crushing equipment

that can be powered from mains electricity

or run self-powered where needed, several

original equipment manufacturers (OEMs)

have introduced a range of dual-powered

solutions to meet customer’s demand for

various power-source configurations.

Dual-powered

crushers

are

both

electrically and hydraulically driven, giving

customers an alternative energy source

to operate their range of equipment.

Dual power crushers are fitted with an

electric/ hydraulic drive system that can be

connected to an external electricity supply

once the machine has been set up on site.

These machines can also be fitted with an

onboard generator, allowing the operator to

electrically power the machine, even where

there is no mains electricity supply.

The dual power system provides flexibility

BEST

OF BOTH WORLDS

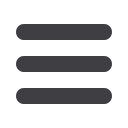

Primarily due to its mobile and versatile nature, mobile crushing equipment

has taken a very important place in operators’ portfolios, especially crushing

contractors. But, with challenging operational conditions driving changes in

priorities, fuel savings and energy efficiency have also become major factors

in influencing buying decisions. To meet the growing demand for flexibility

in power source configurations, several leading OEMs have introduced dual-

powered crushing solutions, writes

Munesu Shoko

.

CRUSHING

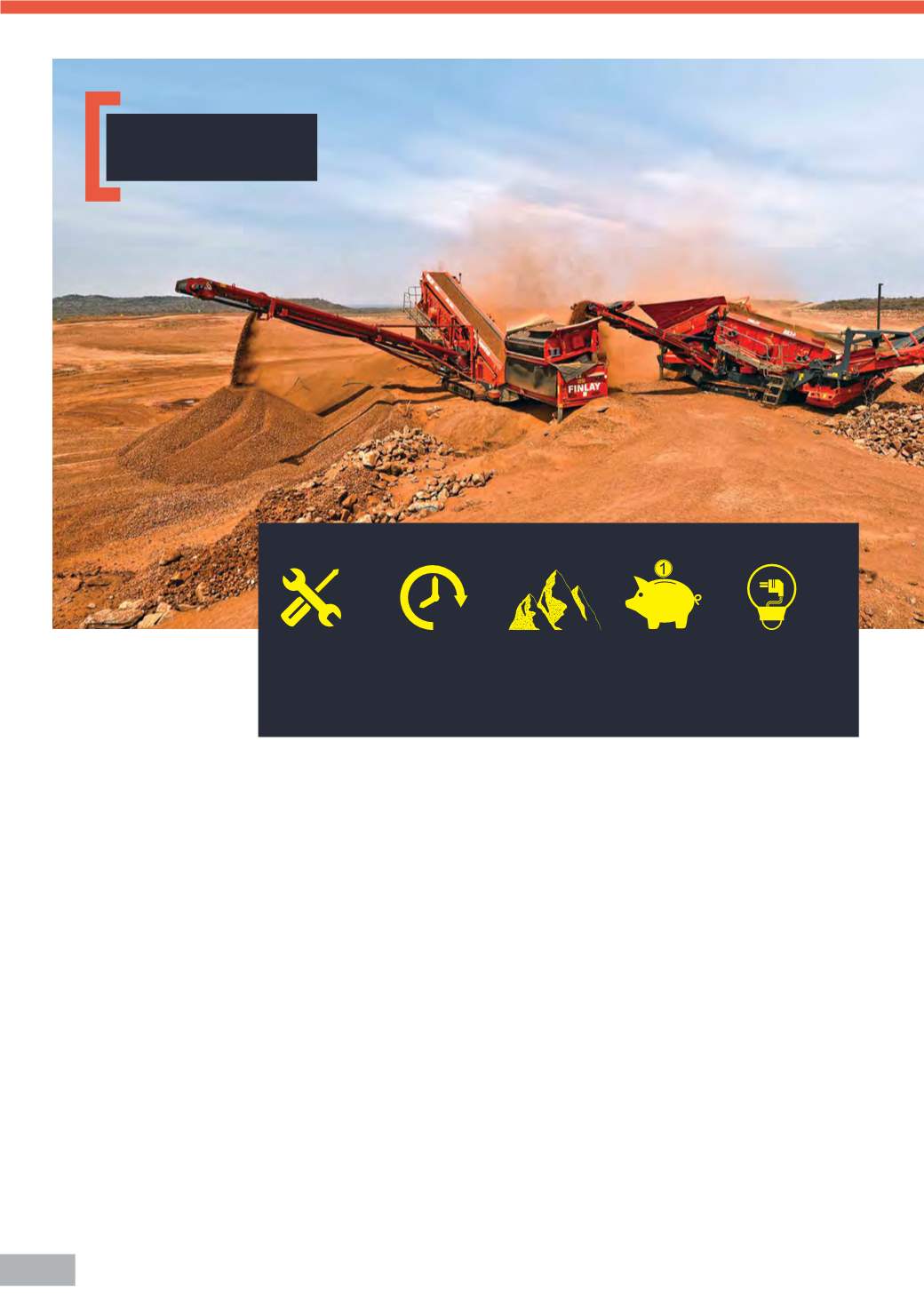

KEY BENEFITS OF DUAL-POWERED SOLUTIONS

Less maintenance

on electric drive

components

Rapid set up time

Offer superior

performance

in dusty

applications and

in high altitude

environments

Savings of up

to 50% when

powered via an

onboard generator

Savings of up

to 75% when

connected to

mains electricity

In 2015, Bell Equipment introduced

the first Terex Finlay dual power

crushing and screening train to the

African market.