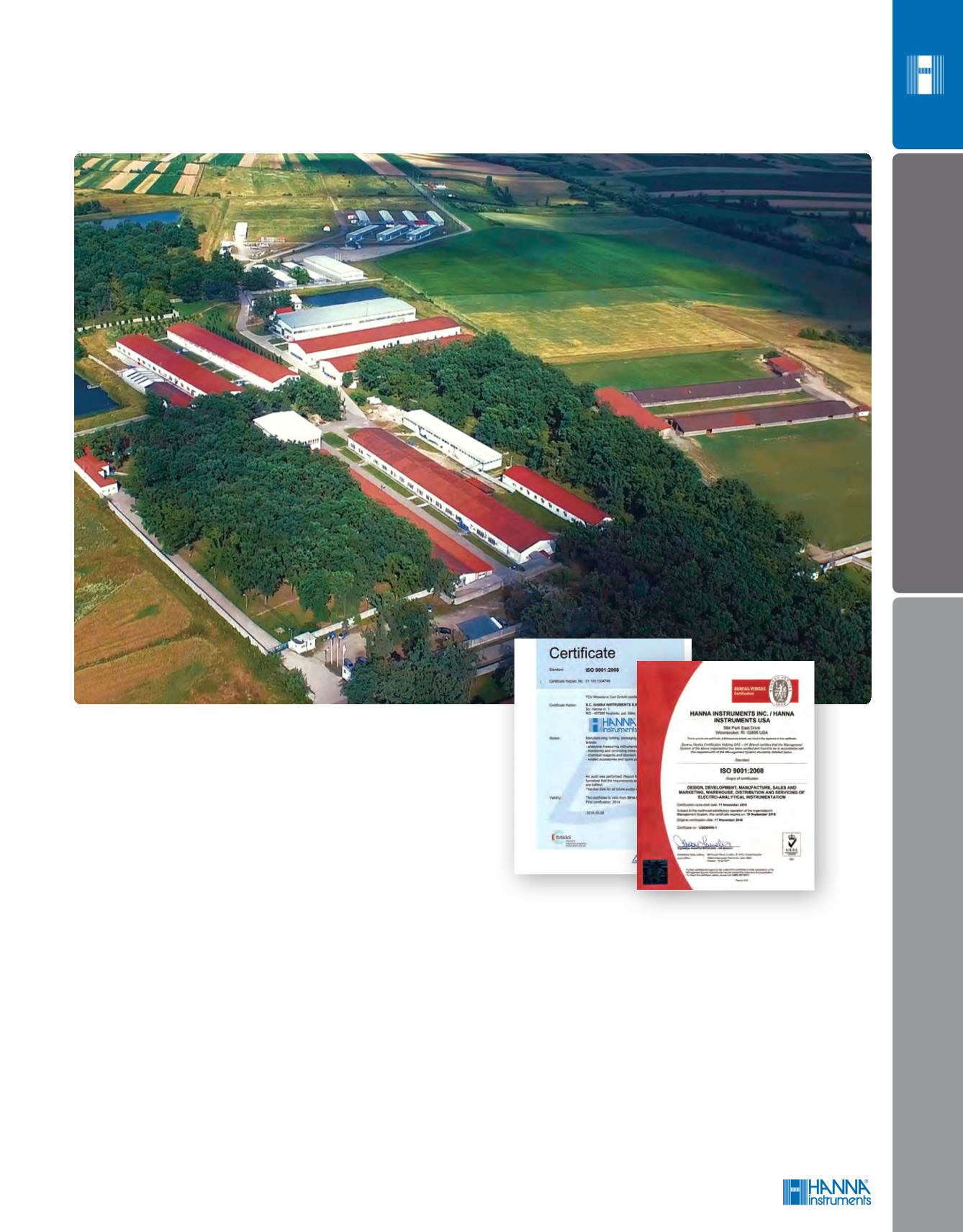

Hanna Design and Manufacturing

In a short time, Hanna has reached its target to produce all of its

instrumentation in-house. Since the introduction of its industrial

science park located in Romania, the facility is equipped to support

all phases of production such as product research and design, plastic

injection molding, electronic assembly, glass blowing for electrodes,

standards production and final assembly of product. Hanna oversees

all aspects of its products from conception to the final quality check

and packaging. Hanna is an ISO 9001:2008 certified company.

Our Woonsocket and Smithfield, RI facilities house our primary

research and development centers and assemble select products such

as titrators, ISEs, HI921 autosampler and HALO®.

Hanna also produces the packaging for all product lines. Each package

is carefully designed for safety and practicality. The in-house control

of all research, design and production steps provides continual quality

control at all phases to assure the highest level of quality.

After continuous validation and testing, Hanna products undergo a final

quality check before they are packaged and released to consumers.

In-house production affords Hanna the freedom to efficiently bring

new and innovative products to market while continuously improving

the quality and features of existing products to meet the needs of

customers.

Production Facilities

Our main manufacturing facility is located on a 100 acre, state of the

art industrial science park in Nusfalau, Europe, with secondary sites in

Woonsocket and Smithfield, Rhode Island in the United States. All of

our product lines are manufactured in-house.

www.hannainst.com|

Introduction

v

about Hanna