CAPITAL EQUIPMENT NEWS

MARCH 2017

36

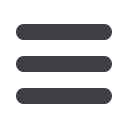

When it comes to the precision and

cost-efficient construction of concrete

pavements and monolithic profiles,

Wirtgen’s slipform pavers are right for

the job. With their modular design, the

machines can be configured as needed,

and virtually all conceivable structures are

possible, including special shapes. The

SP 64i represented the new generation

of slipform pavers at CONEXPO CON/AGG

2017 in Las Vegas.

The SP 60 series replaces the successful

SP 500 – and is said to open up new

possibilities for contractors. More features

than ever operate hydraulically in the SP 60

series. Thanks to a new hydraulic concept,

energy is now used much more efficiently,

making it available for new equipment

options, for example, trimmers and a large

delivery screw for offset applications, or

the four swivel arms used to switch the

machine from transport to working mode

faster. The system starts as a basic version,

and grows along with the number of modular

equipment options selected. Customers save

by choosing only the options they want.

Likewise, the intelligent machine control

systems in Wirtgen’s slipform pavers are

state-of-the-art. Interfaces for the Wirtgen

Group’s WIDIAG service diagnosis and

New SP 60 series from Wirtgen

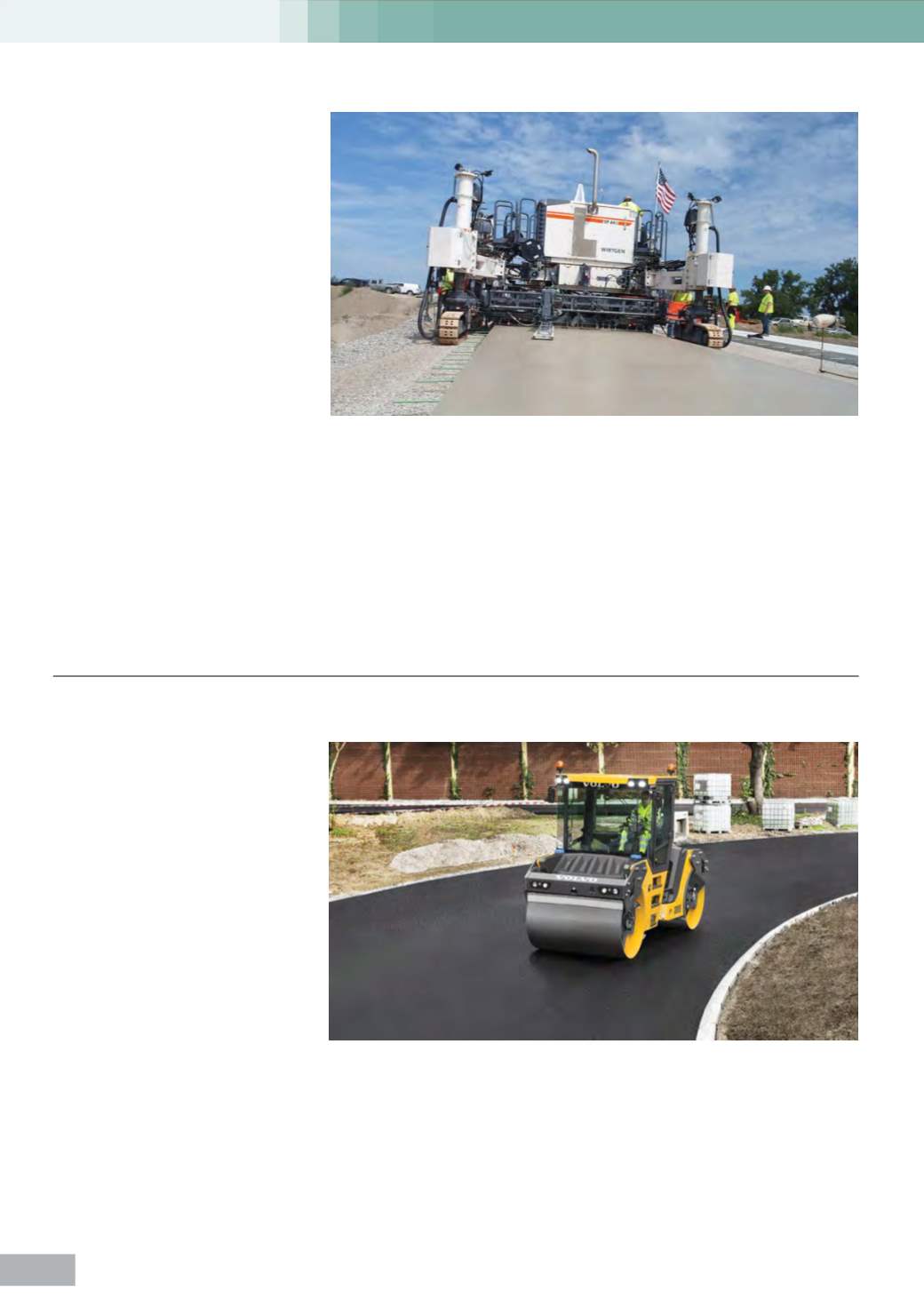

Complete with new oscillation technology,

the DD105 OSC double drum compactor

from Volvo Construction Equipment has the

ability to effectively compact in delicate

areas, such as bridges, over pipes and

close to residential areas.

Fitted with the flexibility of Volvo’s

oscillation technology, which eliminates

vertical vibrations, the DD105 OSC offers

high compaction performance while

producing a non-damaging oscillation

movement. Featuring a 1 680 mm wide

drum with hardened, abrasion-resistant

alloy steel drum shell, the DD105 OSC is

powered by a D3.8 Volvo engine.

In addition to the oscillation technology,

adapting to different jobsites is easy. With

the option of using a drum with eight

amplitude settings or two, changes can

be made according to the surroundings

and material depth, adding further to

the machine’s versatility. Selecting the

amplitude most suitable for the mix

conditions and thickness enables the

operator to reach a higher quality of work

in fewer passes.

The DD105 OSC offers features that are

designed with the operator in mind. The

open ROPS/FOPS canopy and the optional

enclosed cab combine comfort, control and

visibility, ensuring a productive operator

environment. From the air suspension seat,

the operator has a commanding view of the

jobsite, as well as clear sightlines down

to the drum and spray bars, enhancing

safety and rolling precision. The view of

curbs and obstructions is enhanced with

off-set steering, aiding precise compaction.

With ergonomically-positioned controls

and joystick, manoeuvrability is improved

for the operator, who can rely on the Anti-

Slip Control to easily load and unload the

machine without damaging the pavement.

b

Debut for Volvo CE’s new oscillatory compactor at CONEXPO 2017

CONEXPO CON/AGG 2017 REVIEW

WITOS FleetView systems support users,

as does the optional Paving Plus package.

Combined with this package, the swivel

arms can actively circumnavigate obstacles

during the concrete paving process.

The option of hydraulic rotational drives,

available for all SP 60 series models,

provides even better manoeuvrability.

With hydraulic rotational drives, the 90° or

120° steering angle of the crawler tracks

becomes a major advantage, for example

when setting up the machine at a job site.

Another new development is the option

of choosing between two undercarriage

sizes. Why is such an option necessary?

For professional concrete paving at job

sites with unpaved ground, the lanes for

the pavers must be stabilised ahead of

time. However, the larger crawler tracks

exert less contact pressure per unit area,

reducing the pressure on the ground, thus

giving the slipform paver the stability it

needs. This in turn has a positive impact

on the quality of the paving results.

b

The SP 60 series, launched at ConExpo 2017,

replaces the successful SP 500.

The new DD105 OSC is ideal for working in delicate areas, such as bridges, over pipes and close

to residential areas.