>

MARKETPLACE

This outstanding achievement is the result of the exceptional attention

to detail and meticulous care taken by Liviero site teams in their work

areas, comments Brad Boertje, managing executive of Liviero Building.

“Our construction teams’ commitment to constantly striving for the safest

sites sets them apart, and this dedication is reflected in our latest results in

the MBSA’s prestigious, annual industry competition,” he states.

Liviero’s Eskom Wilge site took top honours in Category H, for contracts

between R300 and R500-million, while the contractor’s Jelf Taylor Crescent

site won Category F, for contracts between R75 and R150-million. Liviero’s

Pavilion team took first place in the competition’s Category E, for contracts

between R25 and R75-million.

Liviero was also among the top achievers in Categories D and G. The

company’s Midlands Medical Centre site secured third place in Category G,

for contracts between R150 and R300-million, and its KwaMnyandu Pedes-

trian Bridge contract took fourth place in Category D, for contracts between

R10 and R25-million.

The MBSA National Safety Competition follows on from regional events

in which Liviero also excelled, Boertje reports. The company’s KwaZulu-Natal

sites won five regional awards in this stage of the competition. In addition to

the many site-related awards, Liviero Plant was placed second in the regional

competition for plant and storage yards.

The annual MBSA safety awards ceremony was held at the International

Convention Centre in Durban, during the MBSA’s annual congress.

“We at Liviero are extremely proud of the efforts of all staff and stake-

holders in consistently setting the highest standards in occupational health

and safety,” Boertje concludes.

From left: Itumeleng Leshoedi (MBSA occupational health and safety

manager), Gift Shumba (Liviero site agent), Stephen Mayeza (Liviero

senior safety officer), and Neil Cloete (MBSA president).

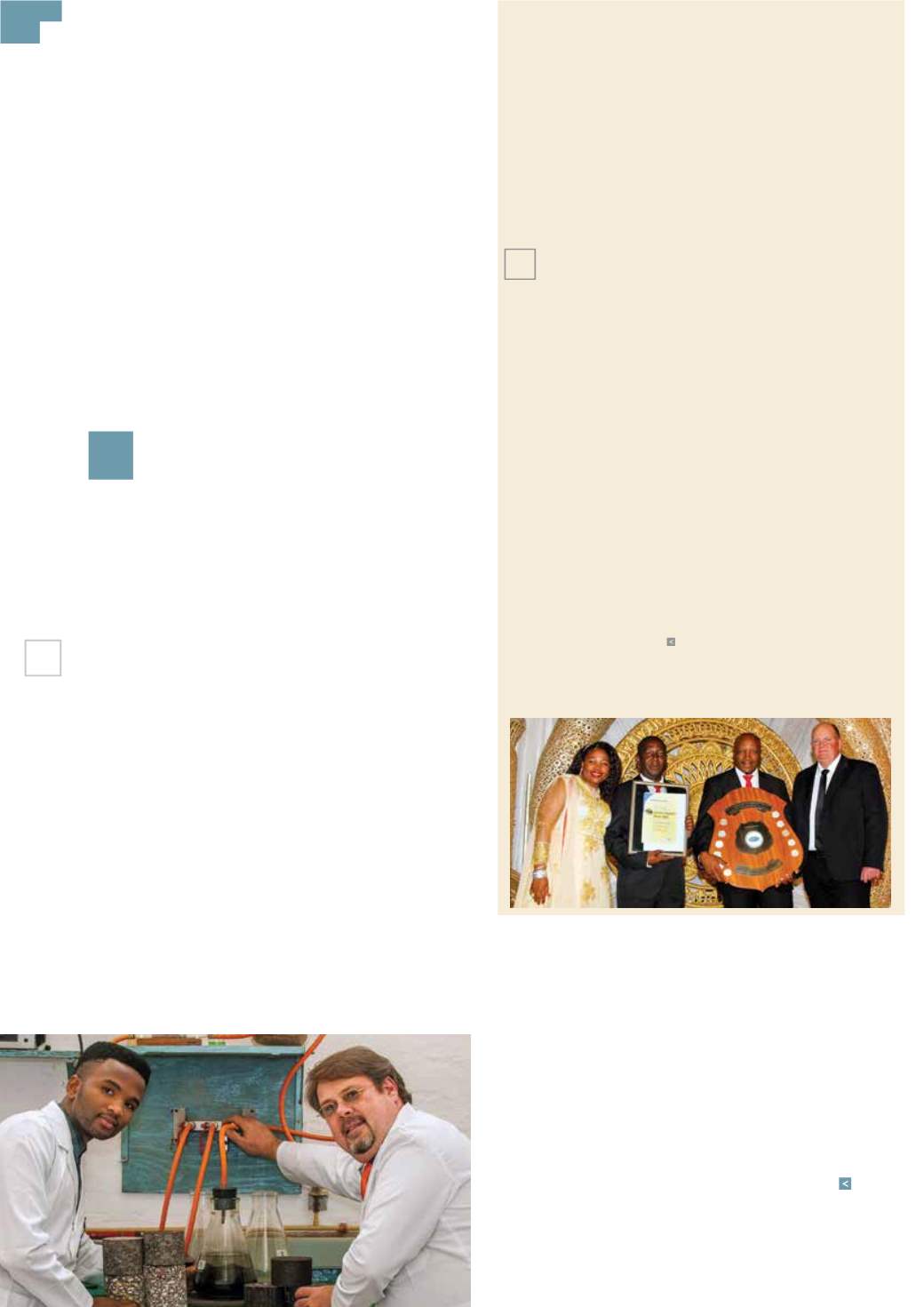

SANRAL will adopt new specifications for the asphalt design

mix and for bitumen. The new specifications are more geared

towards a paradigm of scientific knowledge in comparison to

the South African mechanistic pavement design method.

The new methodology that the agency is adopting will rely on

temperature isotypes or temperature gradient regions in conjunction

with the four classes of traffic volume over road surfaces to determine the

bitumen design specifications. Bitumen is an essential product in road

construction and repair.

The major benefit of pairing the bitumen with the specific require-

ments of the climatic area and the traffic loading is that the longevity of

the bitumen and subsequently, the road surface, can be better under-

stood. From this understanding comes the ability to build roads that can

last longer, which will save tax payers’ money in the long run. SANRAL will

also introduce a new asphalt design method.

“Historically, we have drawn on the empirical method. However, we

have now put a lot of time into understanding the finite elements, and

the new mix design method will be more scientifically-orientated,” said

Sean Strydom, SANRAL southern region materials specialist.

The ability to analyse and predict what will happen in a structural

element over time is the very basis of structural design. This ability is

now within reach of the pavement engineer and the design of asphalt

layers from the same principles as structural design will result in more

cost effective road layers being constructed.

“SANRAL will introduce software drawing on the insight generated

by sophisticated mathematical models for every material layer in the

pavement, from the lower-level granular layers to the more expensive

upper layers which is cement and bitumen stabilised layers. Up until now

we have never looked at how these layers interact with each

other,” Strydom said.

“The software will also allow us to conduct an HDM4 analysis or

analysis of the lifecycle costs,” he said.

SANRAL also announced in March this year the opening of a new

engineering materials laboratory that will see road materials from across

the Eastern Cape now being tested in Port Elizabeth.

NATIONAL SAFETY

AWARDS WINNER

Liviero Building was the proud winner of three

awards in the 2016 Master Builders South Africa

(MBSA) National Safety Competition.

>

Adoption of

NEW

SPECIFICATIONS

The South African National Roads Agency

SOC Limited (SANRAL) has announced

the adoption of two new road materials

engineering specifications for the

construction of the national road network

and other roads under its jurisdiction.

Sean Strydom, SANRAL southern region materials specialist (right), and

Yanga Mshweshwe of SANRAL’s Centre of Excellence determine the theoretical

maximum density of asphalt.

>

The facility will double up as a skills development centre where graduate

engineers in SANRAL’s experiential learning programme can get exposure

to, and focus on, materials engineering.

The civil engineering materials testing lab enables SANRAL to test

the properties of construction materials used in road maintenance

activities as well as in development and upgrading of the national roads.

In addition it will give SANRAL a second-tier quality assessment tool

through comparative or correlation tests done independently from, but

concurrently with, the tests of site material labs conducted on conven-

tional road engineering projects in the province.

“Road materials engineering remains a critical part of ensuring a

world-class road infrastructure network. We are also excited by the new

research being undertaken by Nelson Mandela Metropolitan University in

terms of adding non-homogenous agents such as recycled tyre rubber in

combination with polymer particles into the design mix,” he said.

6

CONSTRUCTION WORLD

NOVEMBER

2016