8

J

anuary

2011

www.read-tpt.com›

I

ndustry

N

ews

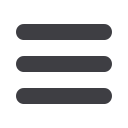

SWAGELINING Limited specialises in the

control and prevention of internal corrosion

in new and existing pipelines. The company

uses polymer lining technologies developed

from a concept originally created by British

Gas and United Utilities.

The company’s official Australian partner,

ITS Trenchless, has announced that it

Largest Australian polymer lining

drinking water project

has secured a $4mn contract with South

Australia’s water utility corporation, SAWater,

to perform the largest polymer lining drinking

water project to be undertaken in Australia.

The contract, which is now underway, will

take approximately four months to complete.

The project involves lining 4,630m of existing

24" nominal diameter water main which runs

beneath one of the busiest

roads in Adelaide.

Stephen

Barnes,

managing director at

Swagelining

Limited,

said,

“Our

patented

Swagelining™

techn-

ology

was

originally

developed specifically for

rehabilitating utility pipes

in challenging locations,

such as beneath busy

roads. The Swagelining

system is highly versatile,

with

liner

thickness

varying from project to

project. In the case of the Adelaide project,

a 594mm polyethylene 100 liner with a wall

thickness of 56mm is being used to meet

the client’s requirement for a liner with full

structural capability. This is in contrast to

another water project recently completed in

the UK where the requirement was for a thin

semi-structural liner, which saw us install a

1,016mm PE100 liner with a wall thickness

of only 20mm.”

Swagelining Limited’s bespoke software

package, which enables the optimum liner

size to be selected to achieve maximum

pull length, established that pull lengths of

over 600m can be achieved for the Adelaide

project, further minimising excavations

and disruption.

Mr Barnes commented, “Unlike open

trenching methods, Swagelining has

minimum impact not only on the community,

but offers significant environmental benefits

as well. These include a reduction in raw

material usage, less waste to be disposed

of, lower noise levels, less dust, and the

ability to complete the project within a short

time frame.”

Swagelining Limited

– UK

Email:

enquiries@swagelining.comWebsite:

www.swagelining.comThe Adelaide project is

the largest drinking water

swagelining project to date