CAPITAL EQUIPMENT NEWS

APRIL 2017

8

JOBSITE REPORT

of hours than we used to get five years ago

on the older models,” says Johnstone.

However, Johnstone cautions that every

good machine is as good as its service. A

stringent service regime keeps these ma-

chines in greater working shape, always

available when duty calls. But, a strict

maintenance regime is only achievable

when parts availability and dealer support

are non-issues. This is where local dealer,

Burgers Equipment & Spares has excelled,

even going the extra mile to meet Balele

Contractors’ extensive support needs.

“Burgers is very much on top of its game.

We have never had issues regarding spares

availability for the eight years we have

dealt with them,” says Johnstone. “They

actually go out of their way to meet our

service needs. For example, one of the

ladies who works at Burgers stays near the

Witbank area and on numerous occasions

when we have to place an urgent part order,

we can order in the afternoon and by close

of business we have our part delivered.”

Burgers is responsible for all service and

warranty issues for the first 2 000 hours.

After that, Balele Contractors’ in-house

maintenance team keeps the fleet running.

Strict service intervals are maintained at

every 250 hours, while a major service

is done every 1 000 hours. Routine daily

checks ensure that there are no alarms that

might trigger bigger mechanical issues.

Keeping faith

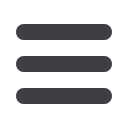

When

Capital Equipment News

visited

the site, two new LiuGong CLG856H loaders

were due for delivery from Burgers, while

four more units were due to arrive in in the

country in April. Continued investment into

LiuGong loaders is paying off big time for the

contractor. “The two main reasons for sticking

to this range of equipment is reliability and

service, not just service from the machines,

but from the local distributor as well,” says

Johnstone. “The aftersales service we

receive from Burgers is impeccable, we can’t

ask for anything more.”

One of the key factors when making

buying decisions as far as mining

equipment is concerned is fuel efficiency,

and the LiuGong machines are not

disappointing in this respect. The LiuGong

CLG856 models are said to range between

14-16

ℓ

per hour, while the newer CLG856H

models are consuming between nine and

12

ℓ

per hour. According to Johnstone,

these consumption figures are about two-

thirds of the comparable offerings from

some premium brands.

Gone are the days when equipment

designs were based on a one-size-fits-all

approach. Today’s equipment designs are

based on customisation, understanding

what each customer’s operational needs

are. This is what exactly LiuGong and

Burgers have done for Balele Contractors.

LiuGong engineers have paid frequent visits to

Balele’s sites over the years, and Johnstone

says the contractor’s feedback in terms of

machine designs has since been incorporated

into the newer models. “Even when we

buy machines, they already know our own

specifications in terms of tyre and bucket sizes.

Our machines are delivered exactly according

to our specifications,” says Johnstone, who

concludes that, before anyone discards

Chinese equipment, they should do their own

homework in terms of both the quality of gear

and local service support.

b

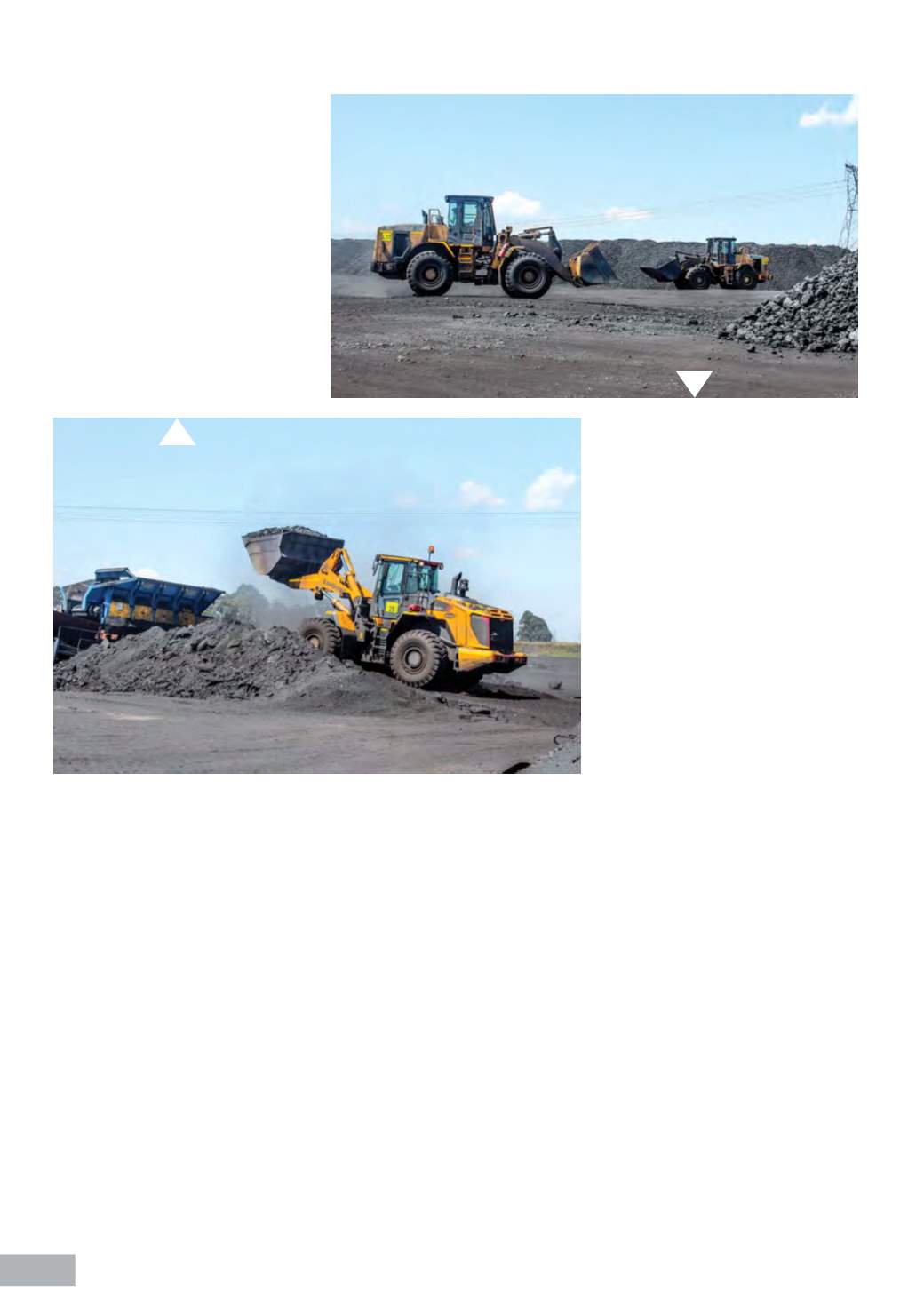

The nine LiuGong loaders are responsible

for all materials handling duties on site.

Distances between stockpiles and the

processing plants are kept at a maximum of

70 m to reduce loader cycle times.