Outotec modular plug-and-play solution for industrial water treatment

In order to be more environmentally

sustainable, the mining and mineral

processing industry is focusing more on

ways to minimise impact on the surround-

ing environment. Outotec has combined

its particular understanding of water

treatment, process design, electrolysis

and hydrometallurgy into a cost-effective

modular product called Outotec®EWT-40.

The Electrochemical Water Treatment

process solution is a highly automated

process, which minimises the need for

personnel while ensuring high quality

water treatment performance.

These EWT solutionsmay be purchased

as a process solution island with full

maintenance, spare parts and operational

support services. Outotec can also offer a

complete water treatment solution from

test work including: laboratory scale test

work to on-site piloting, conceptual and

feasibility studies, basic and detailed en-

gineering, as well as developing a solution

for the entire process.

Potential sources of water contami-

nation from the mining industry include

drainage from surface and underground

mines, wastewaters from beneficiation,

surface run-off and acid mine drainage

(AMD).

Outotec Electrochemical Water Treat-

ment solutions can handle everything

from the removal of arsenic, selenium

and antimony, to trace metals and organic

removal. Customer specific wastewater

can also be tested in Outotec’s lab in

Pori, Finland.

One Outotec EWT-40 module can treat

approximately 5-40 m³/h of wastewater

depending on the application. The opera-

tion can easily be scaled up as needed

simply by adding more modules.

Another benefit of its modular design

is the added value it brings to customers;

the modules can be easily relocated or

resold, protecting the investment beyond

plant lifetime. It is also ideal for remote

locations with minimum transport and

storage needs.

• Fast, efficient water treatment and

lower residual impurities compared to

conventional processes

• Modular design supports easy reloca-

tion and expansion

• Highly automated process minimises

personnel requirements and enables

remote operation and monitoring

• No need to procure or handle

chemicals.

For more information

go to:

www.outotec.comFOCUS ON WASTE

MANAGEMENT

Pompetravaini SpA was founded in 1929

by the late Carlo Travaini, an experienced

machinist with solid production experience

acquired while working at the company

Franco Tosi of Legnano, Italy.

He started his own business under the

name of Travaini Mechanical Machining,

producing many different types of pumps

under private labels with designs and

materials supplied by customers. In the

following years, the ever growing experi-

ence and continued technological updating

of the manufacturing plant increased the

growth potential forcing a major expansion

of the business.

The current President, Ing Mario Tra-

vaini, decided in 1968, to rename the

company Pompetravaini SpA. With tech-

nologically advanced production and a

sales network adequate for the times, the

company began selling products in the

European market under its own label.

Once more the company outgrew its

facilities and in 1982 a new site of approxi-

mately 8000 m

2

was built in the industrial

area of Castano Primo, Milan (Italy).

Parallel to the internal growth there

has been a marketing expansion into

international markets. In 1985 Premier

Fluid Systems Canada started opera-

tion, followed in 1986 by Travaini Pumps

USA. In 1989 Travaini Pompen BeNeLux

was founded in the Nederlands and two

A brief history of the Pompetravaini Group

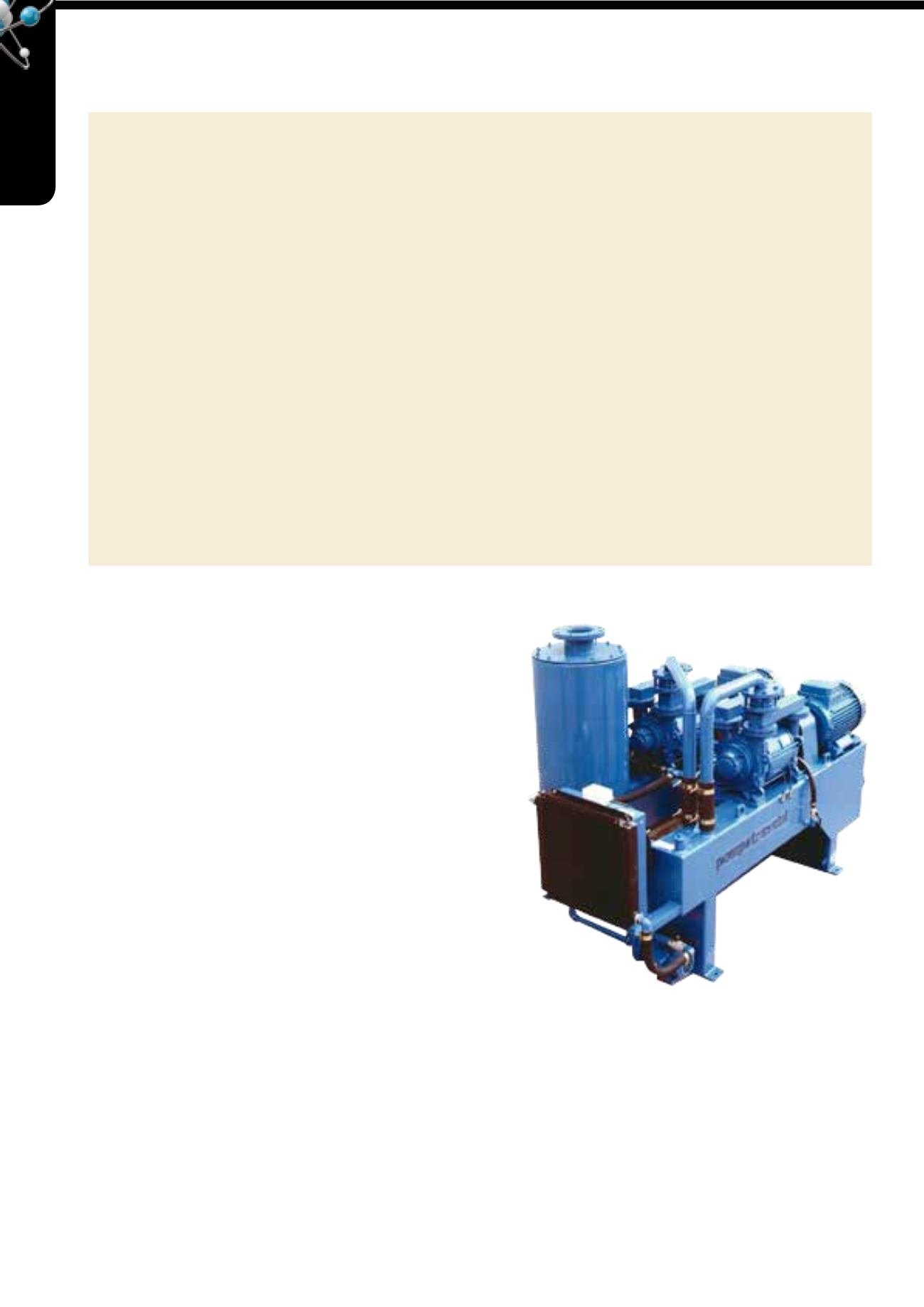

The OilSys Doppio

from Pompetravaini, avail-

able from Vactec in South

Africa

years laterr, in 1991, Travaini

Pumpen GmbH in Germany

began operating. In 1999

Pompes Travaini France

started in France.

In 2002 there was an-

other addition to the existing

plant. A building of approxi-

mately 4000 m

2

was added

to house a new computerised

stock room and assembly

room. This futuristic project

utilises LGV (laser guided ve-

hicles) to store components,

bring them to the assembly

area and then bring the as-

sembled pumps to the test

room.

In 2007 Travaini Pompy Polska was

founded and the following year, after 54

years of total dedication and intense ac-

tivity as President, Mario Travaini handed

over to his son Carlo who has been re-

sponsible for the last steps that moved

Pompetravaini into a new era with ‘state

of the art’ automation.

Various new acquisitions have taken

place since 2012, including NSB gas

processing AG and BORA Blowers; and

FuturEng, an engineering office for design

and construction of skids with rotating

equipment, was founded.

Air & Vacuum Technologies have been

the sole agents for the full Travaini range

for almost ten years now and, according to

Mark Burn, managing director, the brand

is growing from strength to strength with

sales figures growing year on year.

For more information contact:

Mark Burn on 0861 VACTEC (822 832)

or tel: +27 11 318 3240-5;

or go to

www.vactech.co.za10

Chemical Technology • June 2016