WCN

-

www.iwma.org11

WCN

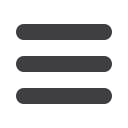

Niehoff chief executive retires

After 20 years as chief executive of the

Niehoff group, Heinz Rockenhäuser

retired at the end of October.

Under the leadership of Mr

Rockenhäuser, Niehoff considerably

expanded its market share and also

set up branches and subsidiaries in

several countries.

During his time as CEO Niehoff

expanded its product portfolio while

the number of employees in the group

worldwide increased from around 500

to 720. The company also built a new

factory at the company’s headquarters

in Schwabach, with the first part of the

plant inaugurated in 2010. Turnover

also increased from €50m to €125m,

consolidated in the whole Niehoff

group to €150m.

Mr Rockenhäuser’s successor is

Arnd Kulaczewski, previously managing

director (CEO) of the press builder

Schuler SMG in Waghäusel, Germany.

Maschinenfabrik Niehoff GmbH

Germany

Email:

info@niehoff.deWebsite:

www.niehoff-gmbh.infoS

S

Heinz Rockenhäuser, left, with Arnd Kulaczewski who has succeeded him as chief executive of Niehoff

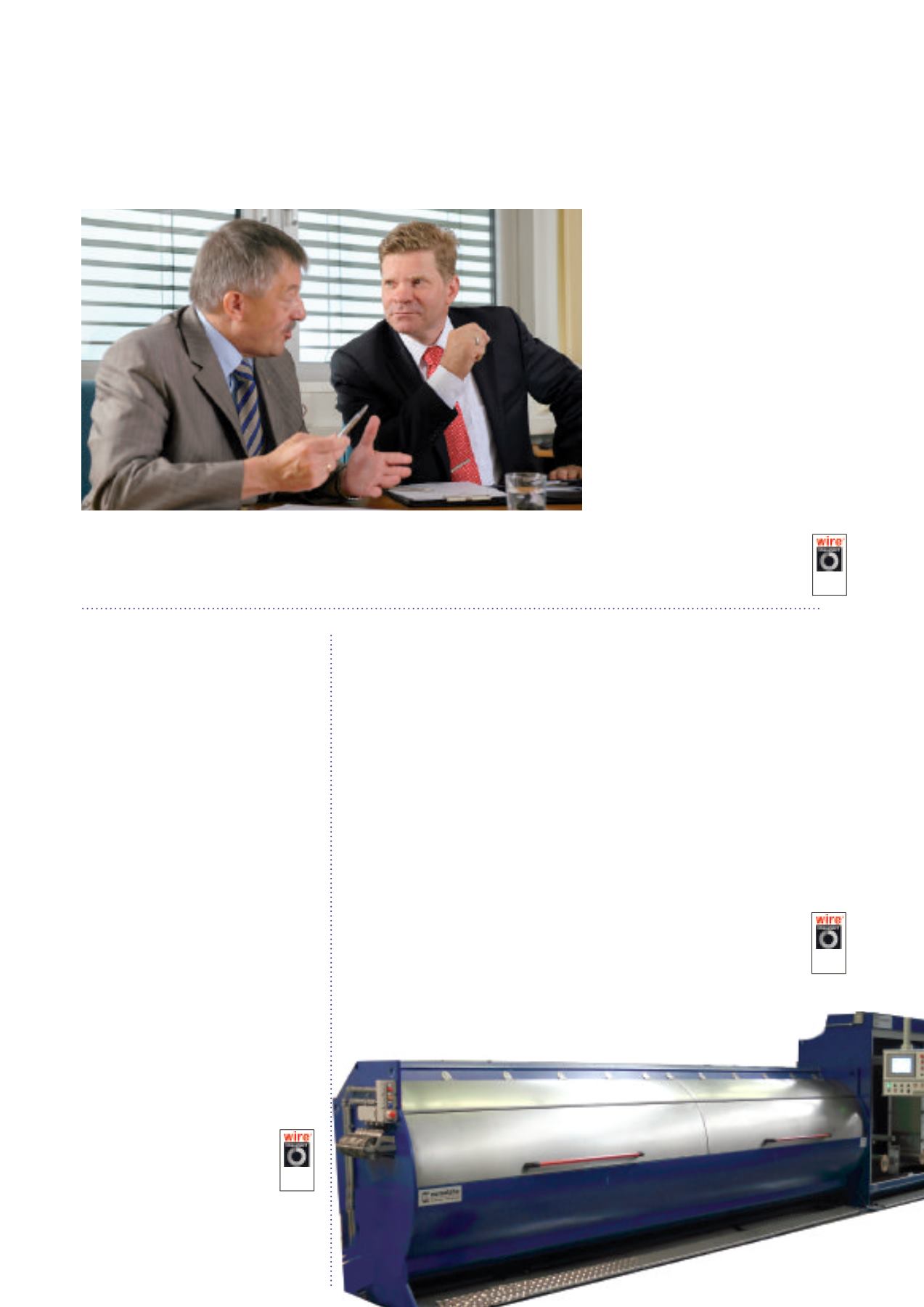

Extending the range

Encouraged by customers, and

based on its deep technical

expertise, Euroalpha has extended

its range of limited-slip drawing

machines to multi-wire: exclusive

equipment that goes beyond the

technology of similar ones currently

available on the market.

D3 is the first multi-wire drawing

machine ever designed with drawing

capstans individually motor-driven,

and up to 32 wires.

Additional drawing modules with

capstans driven by high-precision

gear transmission are incorporated

in the frame for producing thinner

wires.

Such design represents an ideal

solution for cutting the negative

effects of the slip, more consistent

on the slower capstans, and

guaranteeing a rigid mechanical

transmission to the faster capstans,

drawing thinner sizes.

Consistent

energy

consumption

savings,

almost

negligible

maintenance, extreme operational

flexibility (thanks to the variable

elongations the same drawing

machine can produce a very wide

range of finished wires), reduced wire

breakings, low noise level, and other

important benefits of the limited-slip

technology are therefore available on

multi-wire drawing machines as well.

Euroalpha Srl – Italy

Email:

info@euroalpha.itWebsite:

www.euroalpha.itT

T

Up to 32 wires now

available from Euroalpha

Growing number

of customers

With a growing customer database

in the UK and Europe, Anglia Metal

Ltd produces plain and tinned single

end, multi-wire end, bunched and

braiding bobbins in sizes ranging

from 0.1mm to 3.5mm in various

packaging types.

Producing copper wire mainly

within the data, telecom, building,

defence, industrial and automotive

industries, Anglia discusses precise

specifications with existing and

potential customers and is flexible

in the products it produces, always

with the overriding rule that it will

react to customers’ needs.

As a BSI approved company, quality

is the aim and Anglia’s quality and

technical department continues to

provide assistance and guidance to

ensure customer needs are met.

Anglia Metal will be exhibiting at

wire Düsseldorf in hall 12, stand

A34.

Anglia Metal Ltd – UK

Email:

sales@angliametal.comWebsite:

www.angliametal.comStand

12/A34

Stand

11/A43

Stand

10/C18