10

Chemical Technology • March 2016

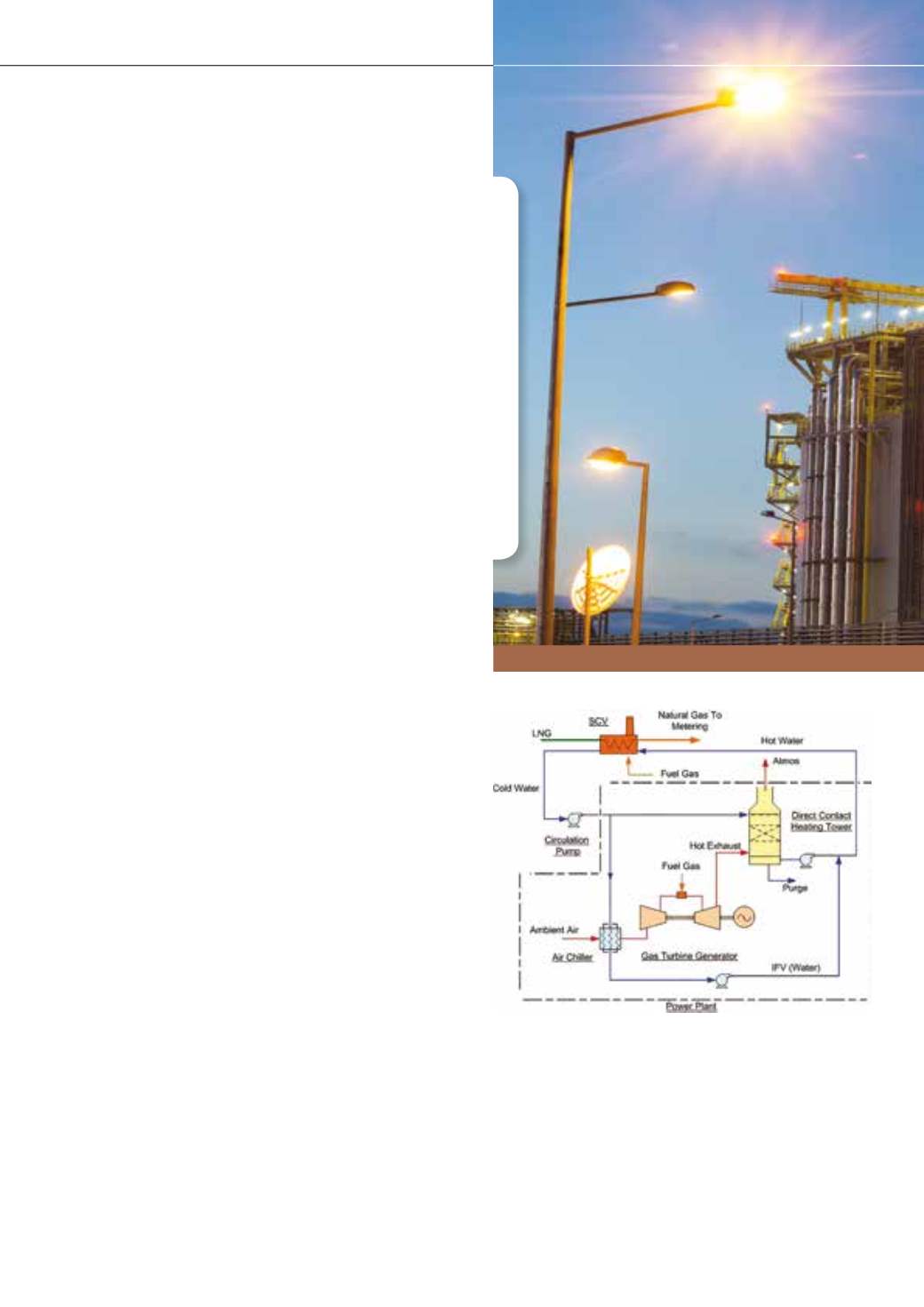

Heat integration with power plant

Simple cycle power plant

W

heretheregasificationplantislocatedclosetoapowerplant,

a hybrid type systemusingwaste heat fromthe gas turbine

and Submerged Combustion Vaporisers (SCVs) for LNG

heating can increase the thermal efficiency of the integrated facility.

The heat integration scheme for a simple cycle power plant can

be illustrated as shown in Figure 7. In this configuration, hot water

is used as an intermediate fluid. The circulating water is heated by

the hot exhaust gas from the gas turbine in a direct contact heating

tower. When waste heat recovery is operated, the fuel gas burners

of the SCVs are not required; the LNG vaporisation duty is supplied

by the circulating hot water.

Fuel firing with SCVs is only required when the power plant is

not operating or when the quantity of waste heat is insufficient to

support the regasification duty.

With the use of waste heat, there are significant energy savings, in

addition to the reduction in CO

2

and NOx emissions from the facility.

In addition, the chilled water from the LNG plant can be used to

lower the gas turbine inlet temperature using an exchanger. This

is particularly advantageous when operating during hot summer

days when the gas turbine output typically drops due to higher

ambient temperature. Lowering the gas turbine inlet temperature

can significantly increase the power output as shown in Figure 8.

Typically, for each degree centigrade drop in air temperature,

power output can be increased by 0,7 to 1,2 % depending on the

gas turbine aerodynamic design characteristics. Typically, aero-

derivative gas turbines are designed with a higher compression

ratio and higher efficiency than industrial gas turbines, and would

benefit more with inlet air chilling, as shown in Figure 8.

Combined cycle power plant

For combined cycle power plants, low pressure steam is condensed

in the surface condenser in the steam cycle using cooling water.

The cooling water return can be used to supply heating to the

LNG plant as shown in Figure 9. This integration method

is cur-

rently employed in the large Grain CHP station to increase thermal

efficiency and reduce emissions. The thermal efficiency of an

Part 1 of this article appeared in the August

2015 issue of

Chemical Technology

. Today’s

LNG landscape is changing. Many of the newer

LNG import terminals are smaller in size and

are mainly located in South East Asia and South

America. These new terminals place a strong

emphasis on energy efficiency, environmental

impacts and emissions.

LNG

vaporisers selection

based on site ambient conditions – Part 2

by John Mak, Senior Fellow and Technical Director,

Nick Amott, Curt Graham, Dhirav Patel, Fluor, USA

Figure 7: Simple cycle power plant integration