8

Wire & Cable ASIA – March/April 2017

www.read-wca.comIndustry

news

Graphics bigstockphoto.com Artist Eky Studio

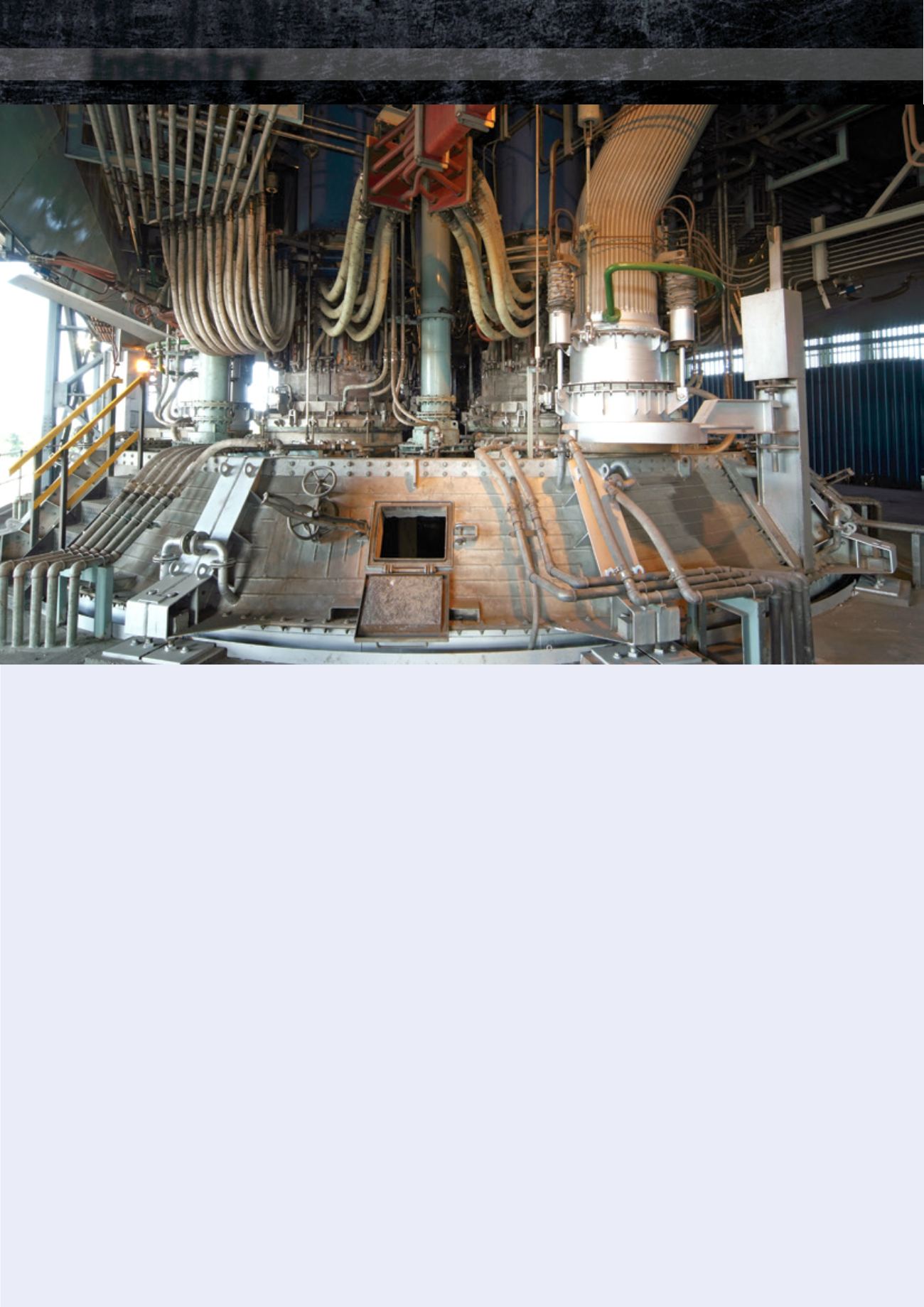

HIGH capacity furnace and smelting plant specialist Tenova

Pyromet has announced that the 45 MVA submerged arc

furnace for the Steel Authority of India Ltd’s (SAIL)

Chandrapur Ferro Alloy Plant (CFP) has been successfully

switched in. Ramping up and tapping of the

silicomanganese (SiMn) furnace, the largest in India, is in

progress.

Tenova Pyromet carried out the contract from SAIL for the

expansion to the plant in a consortium agreement with a

locally-based supplier, GSPL.

The scope of work awarded included design and

manufacture, supply and installation of the complete

furnace and auxiliary equipment, refractories and structures,

followed by testing, commissioning and performance

guarantees.

The plant has an installed capacity of 100,000 tpa

(ferromanganese) FeMn, SiMn and medium/low carbon

FeMn. It is the only public sector unit engaged in the

production of manganese-based ferroalloys in the country.

The fully automated furnace incorporates Tenova Pyromet’s

state-of-the-art equipment, including its electrode column,

and the patented AutoFurn™ Furnace Controller.

This user-friendly system is the ideal way to operate a

“smart” furnace, providing an additional level of automation

above the SCADA and PLC to optimise power input to the

furnace and maintain furnace balance and stability.

All equipment was locally manufactured in India, to optimise

local content, with the exception of the mud gun and drill,

which were manufactured in South Africa.

“This project demonstrates Tenova Pyromet’s extensive

process experience and project execution skills,” says

Andre Esterhuizen, general manager, sales and marketing,

Tenova Pyromet.

“Despite the remote area and language barrier, we delivered

successfully on our commitments to the client who also

recognised the contribution of Tenova Pyromet personnel in

maintaining an exceptional safety record on site.”

With installation of the overall plant 95 per cent complete,

this project has achieved an accident and incident free

record throughout the 6,600 plus hours worked.

The majority of the labour force has been drawn from the

local area as part of the project’s focus on skills upliftment.

Tenova South Africa (Pty) Ltd – South Africa

Website

:

www.tenova.comIndia’s largest SiMn furnace

❍

The switch-in of the 45 MVA submerged arc furnace at SAIL’s Chandrapur Ferro Alloy Plant (CFP) in India