LatestNews

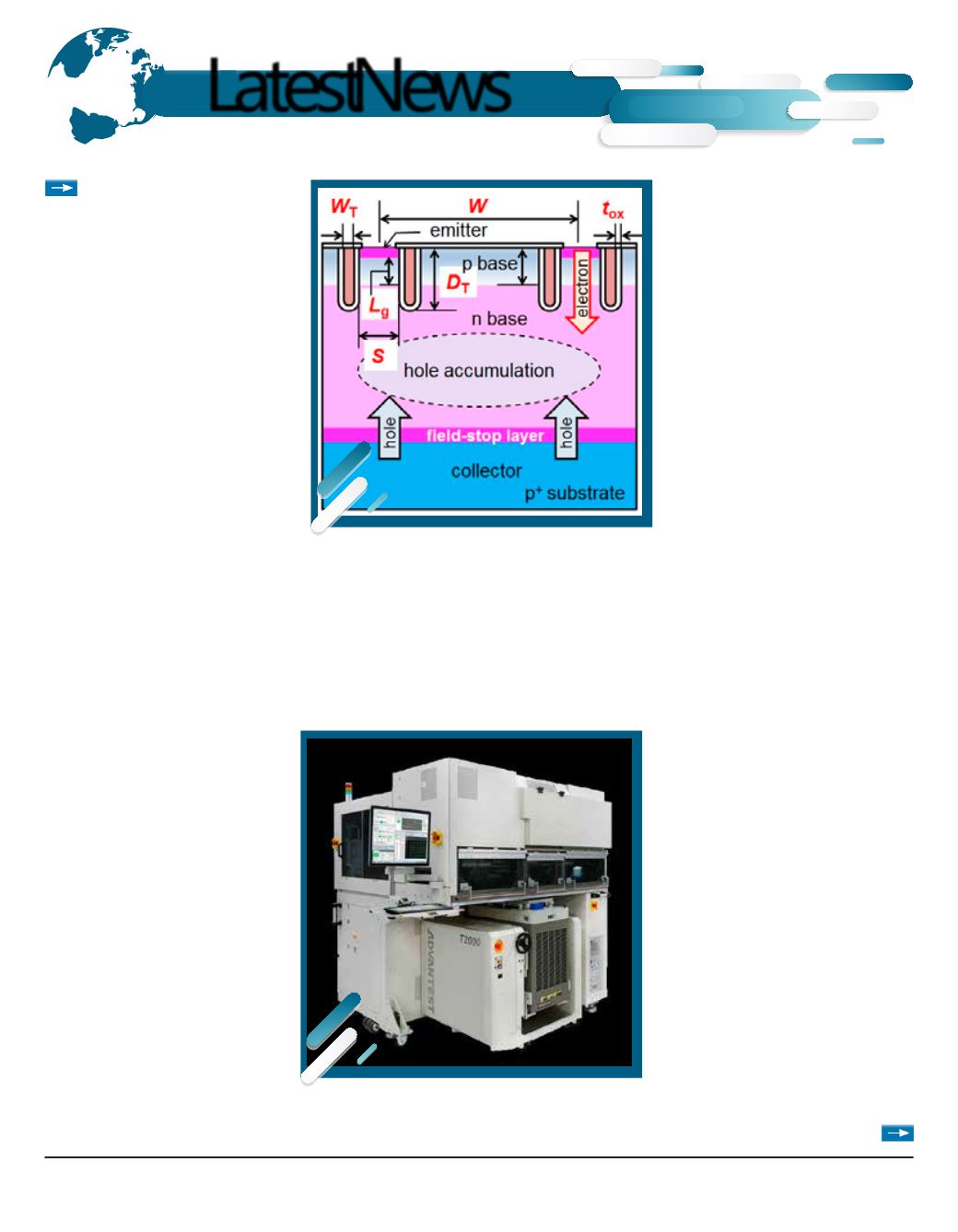

Advantest Unveils New Pick-and-Place IC Handler to Improve

Efficiency in High-Volume Semiconductor Manufacturing and Device

Characterization

Leading

semiconductor

test

equipment supplier Advantest

Corporation (TSE: 6857) has

introduced its M4872 pick-and-place

handler to improve productivity in

testing system-on-chip (SoC) devices

in high-volume manufacturing

(HVM) and device characterization

pre-production environments. This

helps users to keep pace with the

rapidly changing SoC market and

quickly adapt to changes in device

technology.

The new handler matches all of

the leading-edge performance

specifications of its predecessor, the

M4871 handler, including throughput

of up to 15,000 units per hour, in a

footprint that is approximately 10 percent smaller. The portable

M4872 handler has advanced vision-alignment capabilities and

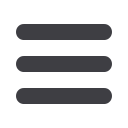

they also reduced the trench

depth by 1/k. Although this

has a slightly negative effect on the

IE effect, it has considerable benefits

for fabrication ease and cost and

the dependence of (Vce(sat)) on

the trench depth was deemed to

be small. The gate voltage was also

decreased by a factor of 1/k, while

the cell pitch was maintained at 16

μm.

Reference

K. Kakushima1, T. Hoshii1, K. Tsutsui1,

A. Nakajima2, S. Nishizawa2, H.

Wakabayashi1, I. Muneta1, K. Sato3,

T. Matsudai4, W. Saito4, T. Saraya5,

K. Itou5, M. Fukui5, S. Suzuki5,

M. Kobayashi5, T. Takakura5, T. Hiramoto5, A. Ogura6,

can accommodate an optional active

thermal control system.

The vision alignment-equipped M4872

incorporates a common change kit,

which saves time and money as well as

helps to safeguard devices under test

from potentially damaging package.

Using a common change kit also

significantly shortens time to market.

In total, the time it takes to change

device types is reduced by more than

45 percent, enabling nearly twice the

throughput of handlers that rely on

standard change kits.

By using Advantest’s on-the-fly vision-

alignment technology, devices under

test can be precisely positioned,

making the new handler ideally suited

for testing fine-pitch ICs and devices with both top- and bottom-

side contacts. The resulting improvements in test yields

Y. Numasawa6, I. Omura7, H.

Ohashi1, and H. Iwai1, Experimental

verification of a 3D scaling principle

for low Vce(sat) IGBT, Technical

Digest of IEDM2016, Session 10.6,

(2016),

http://ieee-iedm.org/1. Tokyo Inst. of Technology,

Yokohama, Japan

2. Nat. Inst. Advanced Industrial

Science and Technology, Tsukuba,

Japan

3. Mitusbishi Electric, Fukuoka,

Japan

4. Toshiba Corp., Tokyo, Japan

5. The University of Tokyo, Tokyo,

Japan

6. Meiji University, Kawasaki, Japan

7. Kyushu Inst. of Technology, Kitakyushu, Japan

12 l New-Tech Magazine Europe