AROUND THE

INDUSTRY

January - February 2015

MODERN QUARRYING

33

SUPPLIER FOCUS

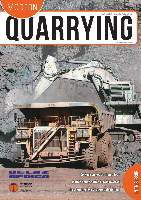

Above:

The addition of an overband magnet to a

modular plant or conveyor system is a customer’s

insurance policy against the risks of mechanical damage

and downtime.

Left:

The revolutionary Sandvik UH450E mobile cone

crusher and screening unit recently completed its first

major contract well ahead of schedule.

programme that rewards customers for

their loyalty. Premio Points will be earned

by all qualifying customers on every pur-

chase they make from our company. It’s

just another way for us to show our appre-

ciation to our customers for partnering

with us.”

The Pilot Premio Loyalty Programme

offers clients up to 2,5% back through the

accumulation and redemption of Premio

points for equipment, spare parts, labour

and services purchased.

“We are very excited about this ini-

tiative,” confirms marketing manager

Yolanda du Plessis.

“The Pilot Premio Loyalty Programme

is an industry first, which gives Pilot

Crushtec International the competitive

advantage and innovative edge we con-

stantly strive towards.”

Premios can be used to pay for spare

parts purchases and/or payment of ser-

vice purchases. Joining this programme

gives Pilot Crushtec International cus-

tomers access to exclusive benefits and

special offers. The programme is presently

limited to South Africa-based customers,

but it is expected to be launched to all

customers this year.

Magnets – an essential component

Pilot Crushtec International has passed

another milestone by selling the 50

th

mag-

net to be used in its Pilot Modular plant

and conveyor systems. What is more sig-

nificant however, is the dramatic increase

in sales over the last few months as more

and more operators realise that magnets

make sound economic sense.

“A magnet used to be regarded as

an optional extra, something that a cus-

tomer would add to the plant at their dis-

cretion. Now they are becoming accepted

as an essential component of our modular

crushing and screening plants,”says Africa

sales manager WayneWarren. He explains

that there are two compelling reasons for

this growing trend.

“The first is security. Significant dam-

age can be caused to cone and impact

crushers engaged in processes like

aggregate production by particles of fer-

rous metal in the feed material. Known

as ‘tramp metal’, this covers a wide range

of potentially harmful objects, including

nuts and bolts, broken grinding blades,

angle iron, small hand tools and pieces of

broken machinery.”

Specific applications where he

believes the integration of a magnet into

a plant is absolutely essential include

most forms of recycling. Post demolition

crushing of concrete and masonry is par-

ticularly problematical as a substantial

amount of building material is steel rein-

forced. The reclamation of disused mining

properties and day-to-day green and rub-

ber waste also contains the risk of dam-

age from metallic objects.

Warren regards the addition of an

overband magnet to a modular plant or

conveyor system as being the custom-

er’s insurance policy against the risks of

mechanical damage and downtime. “The

price of a magnet is relatively insignificant

in comparison to a multi-million rand

plant and is minimal when one consid-

ers the costs of a breakdown. These can

include repairs, freight charges, valuable

items of plant standing idle and com-

mercial pressures related to contractual

obligations. In short, it provides a simple

low-cost solution to what could be a very

expensive problem.”

The second motivation, which has

helped boost the sales of magnets over

the past 12 months, is the fact that they

have added an important new dimension

to a customer’s business. “Magnets are

increasing customers’ operational prof-

its as the ferrous metals which are being

recovered by the magnets are saleable

products and provide an attractive source

of extra income, especially in the case of

a major demolition project. The customer

effectively owns a two-stage operation –

crushing and recycling.”

The magnets are Trio Engineered

Products. The powerful self-cleaning

products are suspended over the feed

conveyor mounted on heavy-duty skid

frames and traversed by a heavy-duty

stainless steel armoured belt. The mag-

nets themselves do not require a power

source and the self-cleaning belts are

electrically driven at a rate of up to 300’/

minute.

They are covered by a global one-

year warranty and both finished prod-

ucts and essential spares are available

from stock in keeping with Pilot Crushtec

International’s commitment to ensuring

its customers enjoy ‘legendary after-sales

support’.

www.pilotcrushtec.com