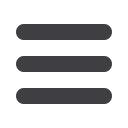

Fig. 1: Typical LCD module block diagram

Data block

Like the timing control block, the

data block in Fig. 1 is also present

in all these PIC LCD modules. It is

composed of the LCDDATAx registers.

After the module is initialised for the

LCD panel, the individual bits of the

LCDDATAx registers are cleared or

set to represent a clear or dark pixel,

respectively.

Specific sets of registers are used

with specific segments and common

signals. Each bit represents a unique

combination of a specific segment

connected to a specific common.

Bias generation block

There are two main methods of

generating the bias voltages – resistor

ladder and charge pump – both of

which can be externally or internally

supported by the device. The LCDref

register determines whether external

or internal resistor biasing is used.

Setting the LCDIRE bit enables internal

biasing.

When internal reference is enabled,

contrast can be software controlled by

configuring the LCDCST bits, which on

some devices are found in a separate

register. The power source for the

contrast control can be selected

through the LCDIRS bit. The LCDref

register also determines which bias

pins are used internally or externally

for the different bias levels.

The LCDRL register provides control

for the different ladder power modes,

as well as the time interval for each

power mode.

Using the charge pump method

requires only the LCDreg register to

be configured. When the charge pump

is enabled, contrast can be controlled

through the bias bits. The regulator

supports either 1/3 or static bias by

setting or clearing the relevant bit. The

regulator also has to be provided with

its own clock source through CLKSEL

bits.

Frame frequency

The LCD frame frequency is the rate

at which the common and segment

outputs change. The clock source

depends on the configured clock

source select bits on the device used;

PIC MCUs typically have three clock

source choices for the LCD module.

The range of frame frequencies is from

25 to 250Hz with the most common

being between 50 and 150Hz. Higher

frequencies result in higher power

consumption and ghosting while lower

frequencies can cause flicker.

Clock sources

The three possible clock sources

on these modules are usually fast

internal RC (FRC) oscillator, secondary

oscillator (SOSC) and internal LPRC

oscillator. However, for some devices

the clock sources are the system

clock, the timer one oscillator and the

internal RC oscillator. Fig. 2 shows how

a clock is typically generated for the

LCD peripheral.

For the three clock sources, a divider

ratio provides about a 1kHz output.

For example, if the clock source is

an 8MHz FRC oscillator, it has to

be divided by 8192 to produce an

approximate 1kHz output. This divider

is not programmable. Instead, the LCD

prescaler bits of the LCDPS register

are used to set the frame clock rate.

These bits determine the prescaler

assignment and prescaler ratio.

Typically, two of the three clock

sources may be used discretely to

continue running the LCD while the

processor is in sleep mode.

Waveforms

An LCD can be characterised by the

MUX ratio and bias, but one piece

of information is still missing – drive

waveforms. LCD waveforms are

generated so that the net AC voltage

across the dark pixel should be

maximised and the net AC voltage

across the clear pixel minimised. The

net DC voltage across any pixel should

be zero. LCDs can be driven by type A

or type B waveforms.

In a type A waveform, the phase

changes within each common type

whereas a type B waveform’s phase

changes on each frame boundary.

Thus type A waveforms maintain 0V

DC over a single frame and type B

waveforms take two frames. Fig. 3

New-Tech Magazine Europe l 39