www.read-tpi.com

www.read-tpi.com

July 2010 Tube Products International

9

news

business & market

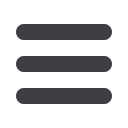

Imatek, a manufacturer of materials

testing equipment primarily in the

fields of impact testing, has installed

a 30,000J DWT40-30, drop weight

tear tester (DWTT) at Ural Steel in

Novotroitsk, Russia. Imatek’s products

are used to test the properties of

materials, components and assemblies

in industries such as aerospace,

polymer processing, steel production,

automotive and academic research.

The DWT40-30 replaces an older

machine and will be used to test the

fracture properties of steel used in the

manufacture of large diameter pipe

for the oil and gas industries. This is

a significant installation for Imatek, as

it represents the company’s first sale

into Russia following the appointment

of new distributor, Uralsibpromservice

(USPS), based in Chelyabinsk.

Ural Steel is a subsidiary of the holding

company Metalloinvest, and is the

largest enterprise in the South Ural

region and one of the eight leading

metallurgical integrated works in

Russia. The company was founded in

1955, and is now a significant niche

steel producer of strips, tube billets,

bridge steel, machinery construction

steel and billets for exports.

The use of higher grade steels in the

oil, gas and manufacturing industries is

creating the need for a new generation

of specialist impact testers. Imatek

offers a range of DWTT systems for

measuring the fracture characteristics

of steel specimens according to API

recommended practice 5L3, EN 10274

and ASTM-E 436. Steel grades of

X120 and specimens of up to 50mm

can be accommodated.

A major feature of the Imatek range

is the high-quality instrumentation

and analysis software that provides

detailed information, both graphical

and tabular, for the specimen failure.

While the DWTT test method does

not require instrumentation, recent

research indicates that it is of significant

benefit when testing the tougher

X-steels. Instrumentation enables

crack initiation, and most importantly

crack propagation energies, for the

specimen to be determined, which

is considered a better measure of

Imatek has installed a DWT40-30 drop

weight tear tester at Ural Steel

Imatek in Russian sale

‘in-use’ performance for these steels

than visual assessment of the fracture

surface.

Imatek Ltd

– UK

info@imatek.co.uk www.imatek.co.ukThe Kuwait Pipeline Technology

Conference & Exhibition, to be held at

the Hilton Kuwait Resort, 6 & 7 October

2010, is a new international platform

for products, systems and services

relating to the transport of oil, gas and

water.

The focus will be on the entire value

added chain, from planning, con-

struction and operation to maintenance

and repair. The conference will provide

participants with practical solutions for

effective planning, design, construction,

operation, corrosion, mitigation and

maintenance strategies applied to

state-of-the-art pipeline networks. The

conference will also present detailed

information and techniques needed

to overcome pressing challenges in

effective planning and management of

pipeline systems.

The Pipeline Technology Conference

combines all pipeline related topics,

including: manufacturing materials

and technologies; pipeline project

management; design and construction;

rehabilitation and maintenance; GIS/

database development; pipeline

integrity

management;

pipeline

automation and measurement; risk and

reliability; protection, corrosion and

monitoring systems; and standards

and regulations.

ProMedia International

– Kuwait

info@kuwaitpipetech.com www.kuwaitpipetech.comKuwait Pipeline Technology

Conference & Exhibition