V

OL

25 N

O

3

M

AY

/J

UNE

2012

CONTENTS

120

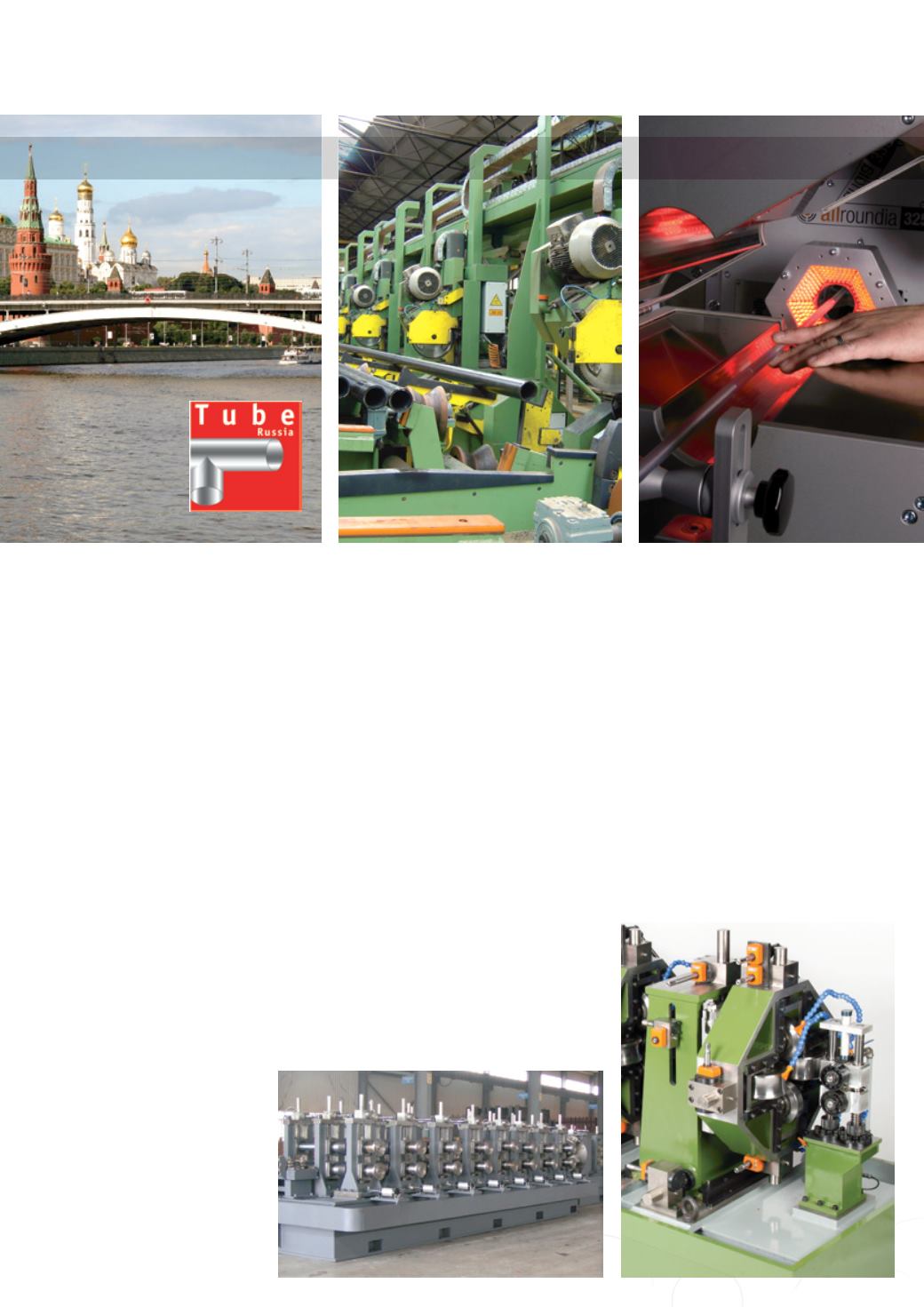

The development of AUTO-DNSA mills and

ERW tube mills

By Guowu Gao, chief engineer, FD Machinery, China

Tube Russia 2012

Economic conditions for the trade

fairs Tube Russia, Metallurgy-

Litmash, and Aluminium/Non-

Ferrous, to be held from 28 to

31 May 2012 in Moscow, are

improving. Despite an extremely

difficult economic environment over

the past few years, the industry is

now looking to the future with a fair

amount of optimism thanks to the

constantly improving investment

climate in Russia.

Cutting, sawing &

profiling technology

Today, an average-size or even a

small tube and pipe plant is likely to

command impressive cutting capacity,

with a single highly flexible machine

able to cut a variety of profiles either at

the end of the tube or along its length.

Employing one tool in a single cycle

to cut round, square, rectangular, flat,

oval, and virtually any other form, the

unit will outperform cutters that only

recently were state-of-the-art.

Inspection, testing

& quality control

Producers of tubes face strict

government and industry regulations

that hold them liable for lapses

in quality. Tube makers to the

automotive industry must provide

product that holds tight tolerances.

Plastic tube manufacturers, even

as they meet challenges as diverse

as the markets and customers they

serve and are under a concomitant

obligation to substantiate their claims.

98

84

100