7

Chemical Technology • April 2015

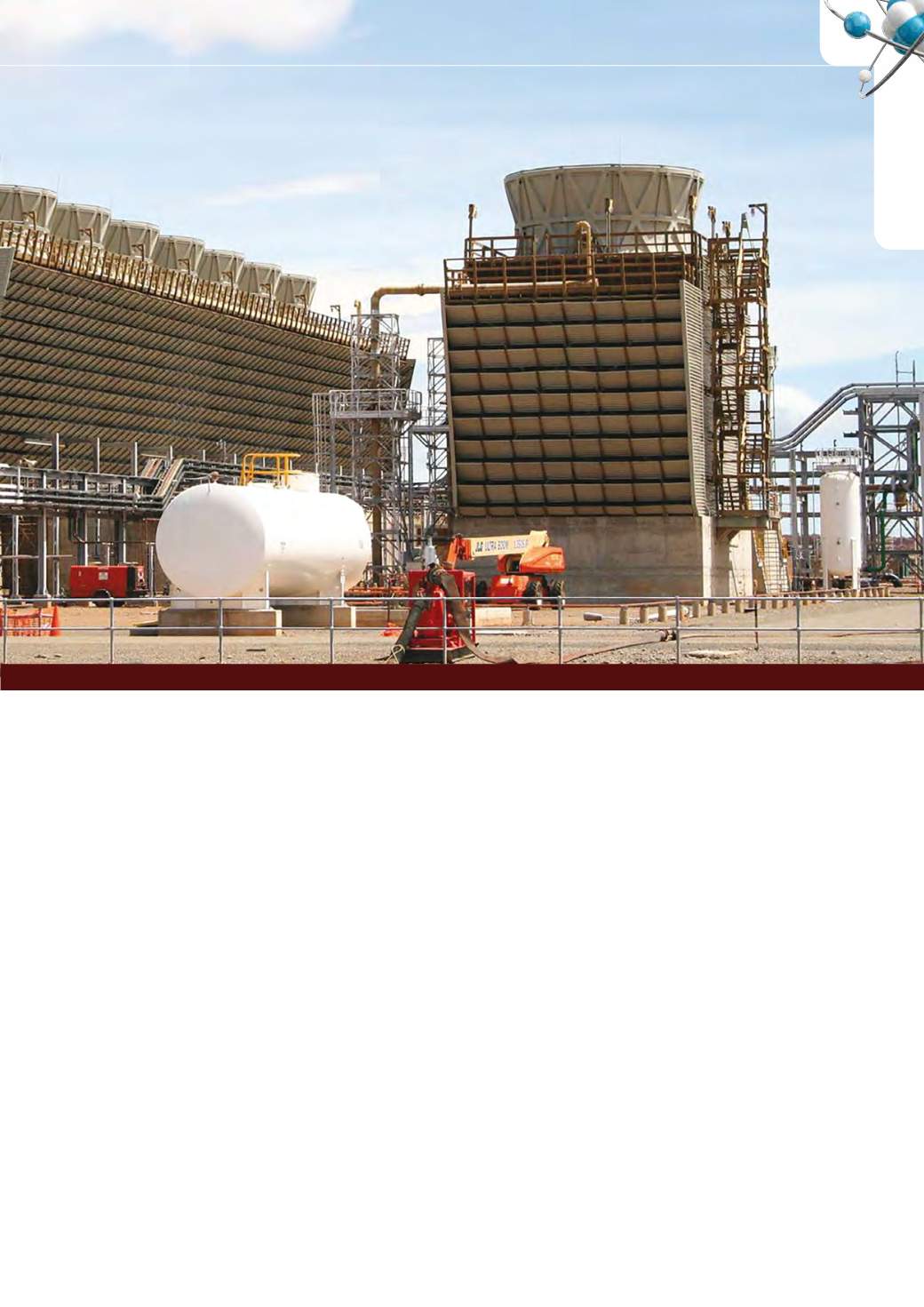

When a cooling tower goes offline it slows production. In some

cases it can even cause the refinery to shut down completely.

Automating cooling towers

On-line measurements are required to provide the data

needed to tightly control cooling towers, maintain the assets

and prevent over-maintenance. Automated monitoring also

prevents failures, thus limiting downtime in each cooling

tower section.

Automated monitoring provides better control to improve

tower efficiency andminimize water consumption. Having the

right data enables proper dosing of the cooling tower water to

prevent excess chemical use, and to provide the right water

chemistry to avoid fouling and damage to the pipes. Proper

dosing also improves cooling tower efficiency as well.

Cooling towers are evaporative coolers and thus are

limited by the wet bulb temperature of the cooling air. Wet

bulb temperature measures how much water vapour the

atmosphere can hold at current weather conditions. A lower

wet bulb temperature means drier air and lower cooling

tower temperatures. Tower performance is calculated as a

function of supply and return water temperature, and wet

bulb temperature.

With proper data, the control system can calculate and

monitor the cooling tower performance index, saturation

index, conductivity, pH, and fan and supply pump health, and

take the necessary steps to control the system or instruct

maintenance to solve a problem. Typical measurement points

include fan vibration, wet bulb temperature, level of the water

supply, pressure and temperature on the water supply and

return, and pH of the water supply.

WirelessHART makes it possible

While it is desirable to make such measurements, the cost

of installing and maintaining conventional 4-20 mA wired

instrumentation can be prohibitive. As noted above, the

process environment around cooling towers is corrosive to

wiring, mainly due to chemical vapours. This means extra

care must be taken in installing wiring, conduit, cable and

intrinsic safety devices in the presence of flammable gases.

In addition, wired instrumentation requires a power supply,

I/O cards to accept the signals, a data acquisition system to

collect data frommultiple sensors, and ameans of transmit-

ting the data back to the control system.

WirelessHART instruments, on the other hand, do not

require much of this infrastructure. Because WirelessHART

devices can be battery-powered, they do not require a power

supply, intrinsic safety equipment or any kind of wiring. The

transmitters send data wirelessly to aWirelessHART gateway,

either directly or through a network of other WirelessHART

devices.

To protect the devices from the corrosive atmosphere,

pump vibration, flow, temperature, level and pH transmitters

can be installed in enclosures mounted near the cooling

tower (Figure 3). Gateways can be located close to the cool-

ing tower, but away from the corrosive environment. Wired

PETROCHEMICALS

Figure 1: Cooling towers at many refineries have old instrumentation, some of it out of service.