19

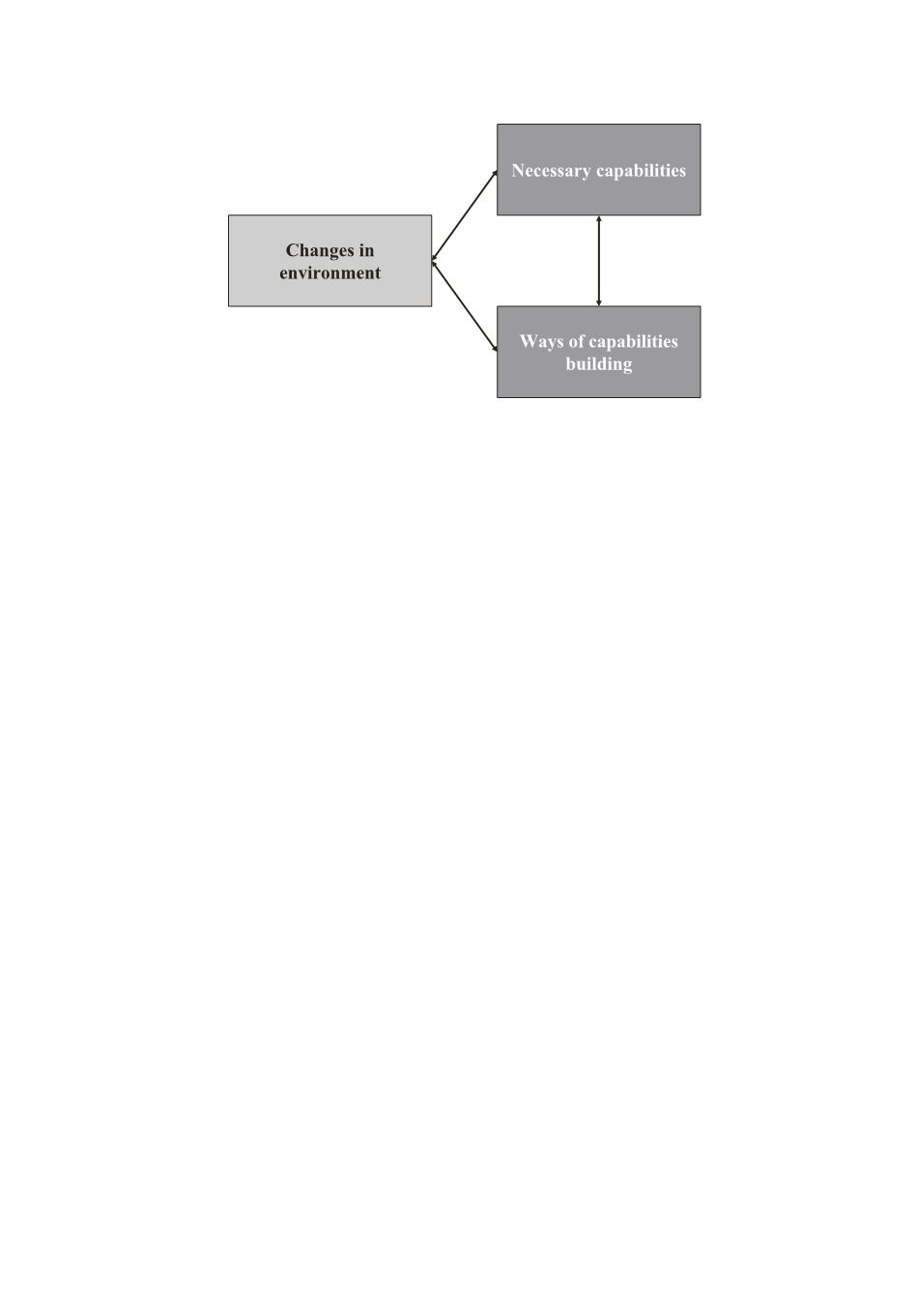

Figure 1.9 Conceptual model of agile supply chain building

1.5 Resilient supply chain management

The basic definition of resilience related to supply chain management comes from

the area of ecology, where resilience is defined as “the ability of a system to return to its

original state or move to a new, more desirable state after being disturbed” [13].

The perception of resilience is very different across recent research. Many authors

are trying to capture the same core meaning of resilience using different words. For an

explanation of the complexity and ambiguity of the problem, recent trends in resilience

definitions are presented here. Resilience is:

• The ability of a system to return to its original (or desired) state after being

disrupted [15].

• The ability to bounce back from large-scale disruptions [53].

• Being better positioned than competitors to deal with – and even gain

advantage from – disruptions [50].

• The ability to maintain output close to potential in the aftermath of shocks [18].

• About building capacity, through the collective and simultaneous efforts of

those in and out of government towards a shared result [44].

• The capacity of an enterprise to survive, adapt and grow in the face of

turbulent change [16].

The main idea of these definitions is to create and manage such supply chain that

is not vulnerable to disruptions. Today’s supply chains must face a wide spectrum of

factors causing their disruption. According to the World Economic Forum (WEF) [63],

the most important ones include: natural disasters, extreme weather changes, conflicts

and political troubles, terrorism and sudden radical changes in demand. According to

the kinds of disruptions identified by WEF and the definitions of resilience mentioned,

the supply chain resilience can be defined as the ability of a supply chain to return to its

original performance in cases of serious disruptions.The influence of these disruptions on

current supply chains is intensified by the following trends in the business environment: