4

MODERN QUARRYING

July - August 2015

AROUND THE

INDUSTRY

A

cquired by the Raubex Group

in 2007, SPH Kundalila has pro-

vided comprehensive materials-

handling solutions for the mining and

construction industry since 1969. In addi-

tion, it has developed significant exper-

tise in related engineering aspects such

as site rehabilitation, road building and

infrastructure development.

This has boosted the company’s

reputation as being a total solutions pro-

vider, with a growing reference base in

the Cape region in particular. “We have

a major footprint in the Western Cape,

while the Northern Cape is becoming

an important focus for us in terms of our

future growth and expansion,” says Johan

Le Roux, business development manager.

“The Northern Cape is a regional focus for

major mining and infrastructure projects.”

At present, SPH Kundalila is carrying

out work at the Port of Saldanha. This was

the company’s maiden contract, and the

source of its name which translates as

Saldanha Plant Hire (SPH). It also oper-

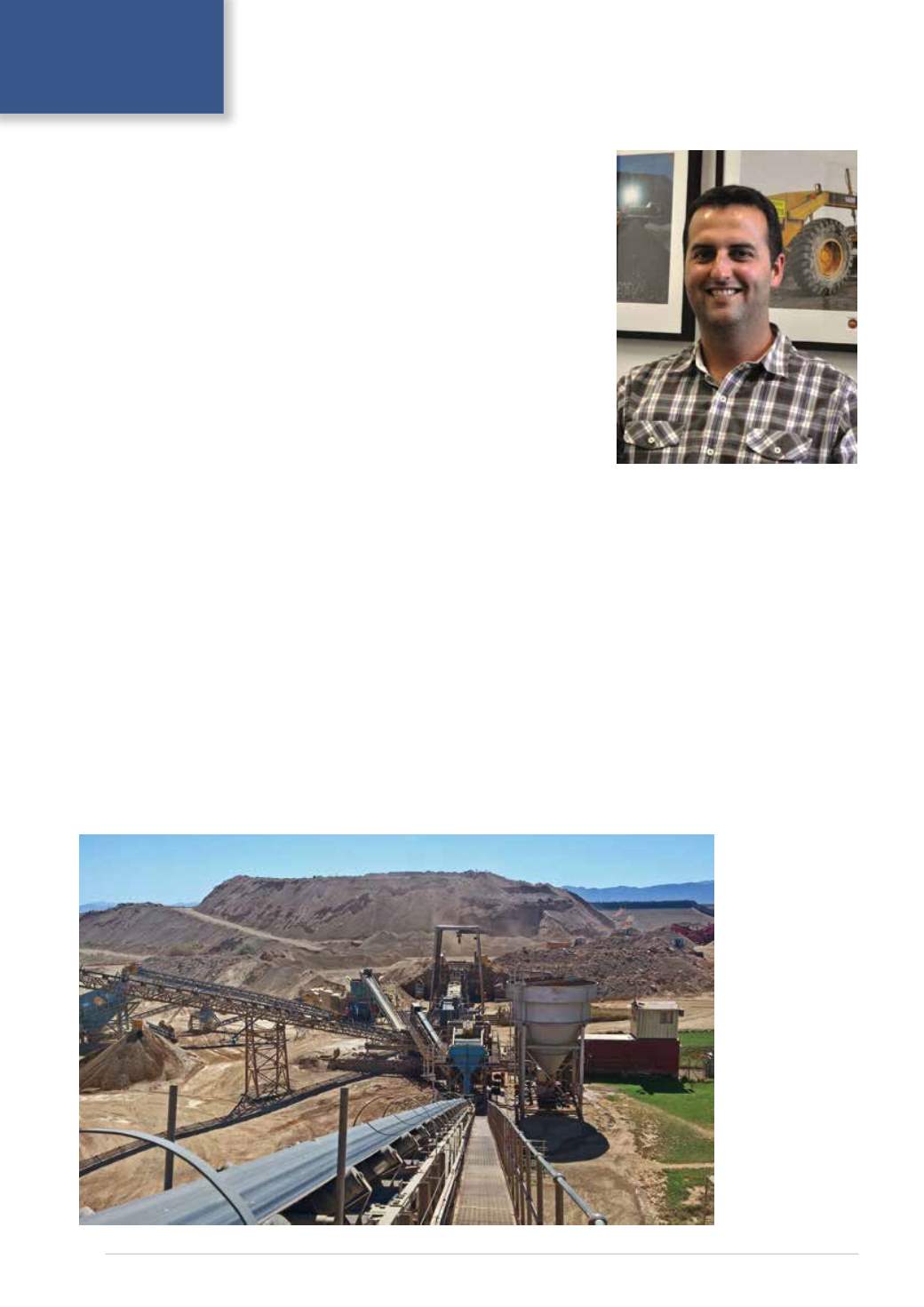

ates a dolomite quarry at Mooreesburg

and an aggregate quarry at Aggeneys.

“Our strong presence in such strategic

SPH Kundalila’s approach to supplying ‘smart’ turnkey solutions for its customers

in the aggregate and mining industries has stood the company in good stead to

become involved in some of the largest projects underway in the Western Cape

region, frommining and aggregate operations to solar-energy farms.

Smart turnkey solutions reap rewards

locations places us in a unique position

to be able to offer a complete service for

our customers,” Le Roux says.

The material from the Aggeneys

operation comprises concrete stone

mainly for infrastructure development,

while the Mooreesburg operation pro-

duces material specifically for Saldanha

Steel’s furnace operations. In addition,

Mooreesburg produces agricultural lime

for use in the farming industry, which is

stockpiled and sold to farmers during

the peak planting season at the begin-

ning of the year. This single-source lime

material is of a particularly fine quality

compared to competitor products, which

are traditionally blended with additional

materials.

“Anticipating customers’ future needs

is one of our differentiators and with the

mining industry being under pressure, we

need to remain flexible and responsive

and ensure that we offer customer opti-

mum performance at all our contracts.

We have a well-maintained fleet of equip-

ment which ensure reliable operation at

all times,” Le Roux says.

SPH Kundalila boasts a major fleet of

350 pieces of equipment, including the

largest number of Caterpillar 950 loaders

in the Southern Hemisphere. “We have a

strong replacement policy which ensures

our fleet remains up to date and incor-

porates the latest technology. It is critical

that our equipment operates at optimal

efficiency at all times, which increases

the productivity of our operations and

reduces running and maintenance costs,”

Le Roux confirms.

The company recently secured a large

aggregate supply order for a major cus-

tomer who is supplying readymix con-

crete and earthwork services for various

solar-energy projects in the Northern

Johan Le Roux, business development manager

at SPH Kundalila.

A plant operated by SPH

Kundalila at Mooreesburg

about 90 km north of Cape

Town in the Western Cape.