February 2017

•

MechChem Africa

¦

9

⎪

Plant maintenance, lubrication and filtration

⎪

for SouthAfricanplants is betweenLevel 3andLevel 4,

with sound preventative approaches being used along

with some key optimisation initiatives.

Compared to maintenance management, the con-

cept of asset management takes amuch broader view

of operational assets. “Whilemaintenance is confined

to keeping equipment operating, asset management

looksatthewholelifecycleofaplantoroperation,from

the identification of need for newequipment; through

the conception, design, constructionandprocurement

processes; through the operate and maintain phase;

and all the way to winding down, decommissioning

and disposal.

“RenewableenergyplantsinSouthAfrica,forexam-

ple, are designed to last for 20 years, in linewith envis-

agedpower purchase agreements (PPAs). Accordingly,

the investment business cases are calculatedbasedon

that premise, and plant asset portfolio designs follow

suit. After a two-year upfront EPC phase, the plant

must be operated andmaintained for 20 years, so this

stage makes up 90 to 95% of its total life.

“Practically speaking, formal asset management

doesn’t reallymake sense for a small workshopwhere

one or two experienced people knowall themachines.

But as soon as an organisation starts to need a dedi-

cated maintenance facility and risks become appre-

ciable, then aspects of the formal asset management

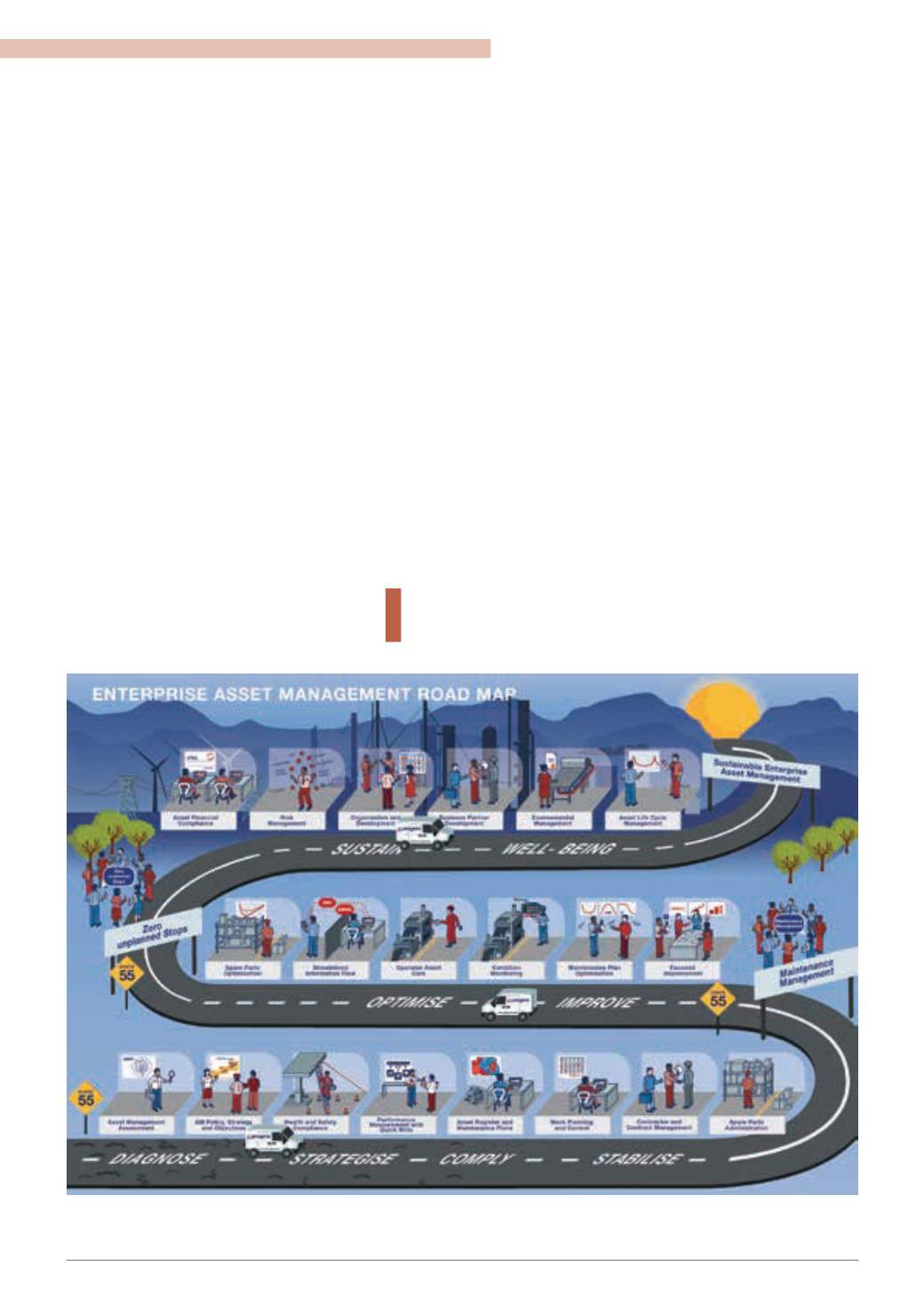

Called AMIP – Pragma’s Asset Management Improvement Planning Road Map is a comprehensive framework consisting of a structured set of processes, policies

and best practices.

the Road Map

approach can be productively applied.

“To help companies implement the system, Pragma

hasdevelopeditsAssetCareCentreconcept,whichisa

contractedoutsourcing service, with its computerised

asset management software system called On Key as

its base. Maintainability and reliability can improve

significantly and risks contained, the value of which

will almost always exceed the costs of adopting a struc-

tured approach to asset management,” he suggests.

“It almost always makes sense for large asset-

intensiveoperationssuchaspowerplantsorrefineries,

processplants andmanufacturingcompanies,” headds.

As part ofmaturity assessment of anorganisation’s

asset management practices, the difference between

the actual maturity and the target maturity preferred

by the client are measured. Called gap analysis, this

is used as the starting point for developing an Asset

Management Improvement Plan.

A typical improvement plan is implemented over

a period of between one and three years. “Following

the identification and implementation of some ‘quick

wins’, most of the initial work involves a phase that we

call ‘stabilisation’, starting with the compilation of an

Asset (equipment) Register as thebackbone. UsingOn

Key, we can usually clone asset types across different

locations to reduce the burden,” Nepgen says.

“It almost always makes sense for large asset-intensive

operations such as power plants or refineries, process plants and

manufacturing companies,” Nepgen adds.