CAPITAL EQUIPMENT NEWS

SEPTEMBER 2016

4

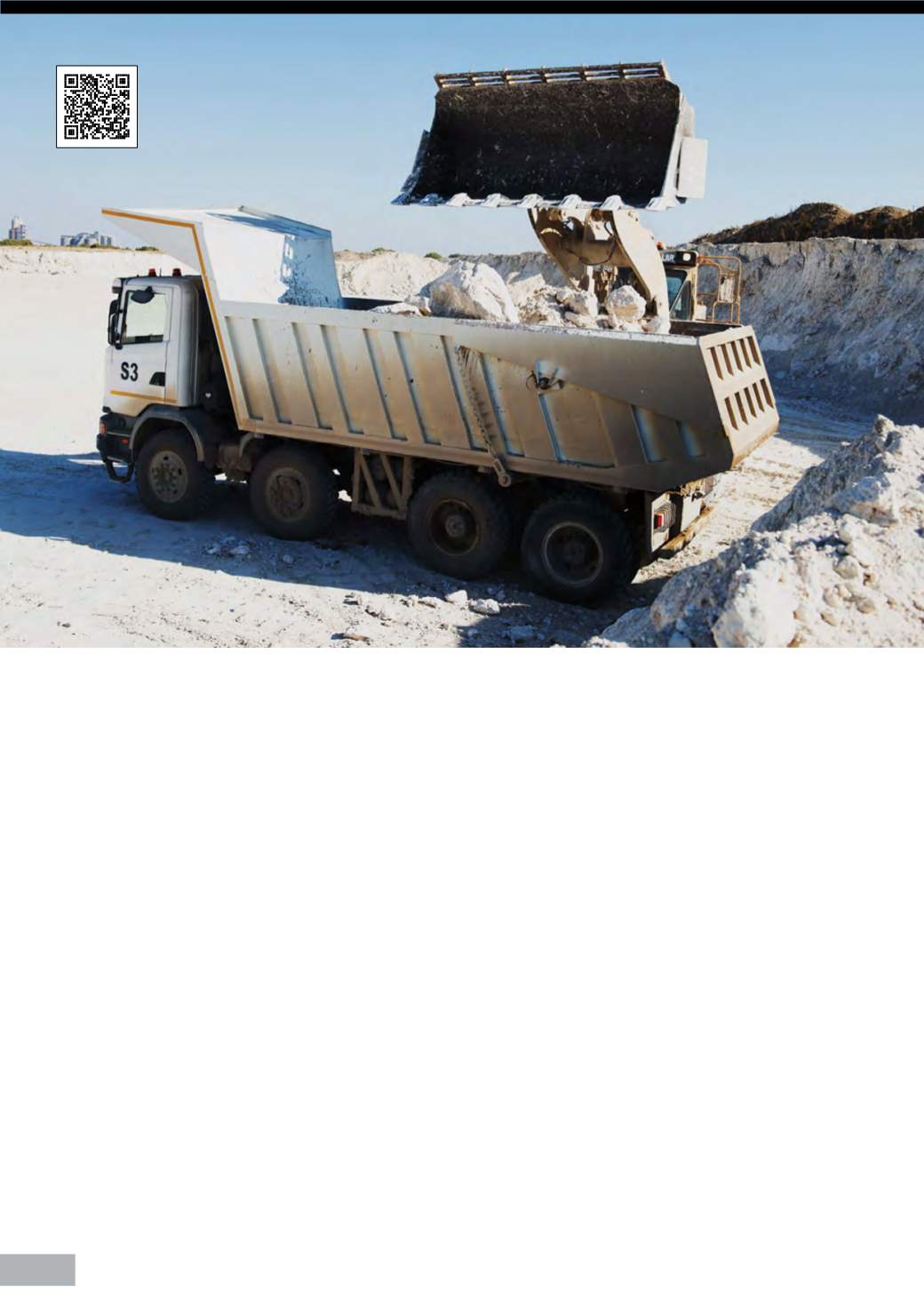

T

he downward commodity pric-

es, exacerbated by decreasing

mineral ore bodies, continue to

put the local mining industry

under immense pressure. Becky

Smith, general manager of Mining at Sca-

nia Southern Africa, alludes to the fact

that mining is in dire straits and “has been

a tough go” for industry players. Bearing

in mind that transport accounts for up to

a third of operational mining costs, she

is of the view that, now more than ever,

mining houses need to rethink their onsite

transport solutions to optimise every stage

of their processes for better productivity,

feasibility and profitability.

With that in mind, Scania will use

Electra Mining Africa 2016, scheduled for

12-16 September, to showcase the full

width of its mining range, from tippers and

service vehicles through to staff solutions

and ADR vehicles. Some of the key exhibits

in this regard will include the the G410 8x4

mining tipper and the G360 6x6 chasis,

the ground-breaking Staff Carrier and the

G410 CB 6x6 Nitro Unit for the explosive

industry. This will be complemented by a

range of engines for industrial applications

and power generation.

Challenging the norm

With its mining tipper range, Scania is

challenging the conventional yellow met-

al, “bigger is always better” mentality of

the local mining sector. Smith agrees that

local miners have over the years grown

accustomed to their articulated and rig-

id haulers. “That’s one thing we are very

mindful of. We are up against a yellow

metal equipment mentality that believes

bigger is always better,” she says. Smith,

however, argues that mining has since

evolved and profitability is heavily reliant

on carefully controlling operating capital

investments and operating costs.

The Scania G410 8x4 mining tipper, for

example, comes with an array of features

and benefits that fly in the face of conven-

tional hauling solutions such as ADTs and

RDTs. The tipper comes with a payload of

between 32 and 34 t, depending on appli-

cation, core density of the material and the

type of body. Smith says that it can there-

fore compete very much on par with a con-

ventional hauler with a payload of anything

between 30 and 60 t. “You may require two

Scanias to replace a 60 t ADT, for example,

but the outright capital investment is much

lower, operating costs are much lower,

SCANIA GOES MINING AT ELECTRA

The local mining fraternity is facing new and tough challenges,

and only a stronger focus on cost-efficient solutions and

operational excellence will keep mines in business. Scania will

use Electra Mining Africa to showcase its holistic approach

to mining with a full range of offerings geared at increasing

customer profitability, writes

Munesu Shoko.

Scan QR code to watch the

interview with Becky Smith,

GM of Mining at Scania.