Mechanical Technology — September 2015

5

⎪

On the cover

⎪

– two wagons hard coupled together with

a rotary coupling between each pair. This

arrangement allows for tandem tippling,

where two hard-coupled wagons are

unloaded simultaneously,” says Tellier.

At the Majuba power station, one of

Eskom’s largest power plants (4 110 MW)

and one of the few without its own dedi‑

cated coalmine, a random rotary tippler is

being used to accommodate rail delivery

of 0.42 Mt/month (14 000 t/d) from

coalmines in Ermelo. A further 0.74 Mt

is delivered less efficiently by road, us‑

ing approximately 700 trucks per day.

“Trucking is currently necessary because

of the inadequate railway infrastructure to

power stations, but it does not help the

overall efficiency and productivity of our

plants,” Göing suggests.

Rotary tipplers are designed so that

the turning point coincides with the axis

of rotation of the wagon couplings in

the tippler. “These systems require deep

bunkers underneath the rotary tippler

to accumulate the material. Both single

and tandem rotary tipplers are available,

depending on throughput requirements

and coupling arrangements on the unit-

trains,” he explains.

Adds Göing: “There are two types

of rotary tipplers, the O-type and the

C-type. The C-type design has an open‑

ing to the one side to allow the wagon

positioner to pass through the tippler

unhindered. If using an O-type tippler, the

wagons need to be pushed into and out of

the tippler from further up or down. There

is a small time savings associate with a

C-type tippler, because the positioner

can operate closer to the wagons being

pushed into the system.”

Positioners and clamping

Before tippling, the wagons need to be

accurately positioned into the tippler

so that they can be securely clamped

and safely rotated. A positioner fitted

alongside the railway line performs this

function. A hydraulic arm swings down

onto the wagon couplings between

wagons and pushes the train or the rake

of wagons along the track, moving the

empty wagons out of the tippler and the

following loaded wagons in. “Modern

positioners are driven on a rack and

pinion system by a hydraulic or electric

drive. These systems move the entire

train and position the wagons to within

a centimetre,” Tellier informs

MechTech

,

“and this is all done automatically with

the positional accuracy being ensured

by an advanced control algorithm and

feedback sensors”. “Multi-body dynamic

simulations are used to correctly size

the positioner drives and to optimise the

positioner control algorithm,” he says.

Once positioned, the wagons are

locked onto the tippler using a clamping

system. “We are globally renowned for

our hydraulic clamping system, which

is a lightweight, flexible and efficient

modern system, but gravity clamping

has become preferred in South Africa –

and as world leaders in tipplers, we can

offer gravity clamping solutions just as

easily,” Göing assures. Gravity clamping

works off mechanical linkages and coun‑

terweights, which cause clamps to lock

onto the top edges of the wagon as soon

as the tippler begins to rotate.

Showing a Scada image on a wagon

tippler, Tellier points out the feeder bins

underneath a rotary tippler. “Each tip‑

ping action is depositing 80 t (single) or

160 t (tandem) of material into the bins

below, and you want to make sure that

the material is able to flow smoothly and

continuously onto the conveyors and

that the bulk does not hammer directly

onto the vibratory, apron or belt feeder

below. So the levels of the bins and the

belt loading rate is carefully controlled to

optimise material flow and to best match

the wagon unloading rate,” he explains.

The ore from the wagon tippler is

channelled into separate bins below the

system, and the level of each of these is

carefully monitored – typically by using

3D radar measuring technology from

Indurad – and automatically controlled

to balance the output flow with the

batch unloading of the wagons. “These

systems can deliver at 6 500 t/hr, so

several feeders are required to match the

unloading speed and remove the material

fast enough,” he adds.

“We are a local OEM capable of de‑

signing and manufacturing entire wagon

tippler systems – the tippler, positioners,

bins, apron feeders and conveyors – to

smooth the flow of material while al‑

lowing wagons to be emptied as fast as

possible,” says Göing.

“And in addition to ThyssenKrupp’s

wagon tippler offering, we can offer

solutions from the mine stockyards and

load-out stations, through the rotary

tipplers and all the way to the stackers,

reclaimers and ship loaders. Our modern

solutions enable efficient transportation

of bulk materials that can significantly

improve the competitiveness and long

term sustainability of local mining opera‑

tions,” he concludes.

q

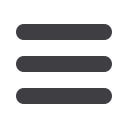

Above:

ThyssenKrupp’s most current success, a state-of-the-art ThyssenKrupp tandem rotary tippler at the Port of Nacala. These systems require deep

bunkers underneath the rotary tippler to accumulate the material.

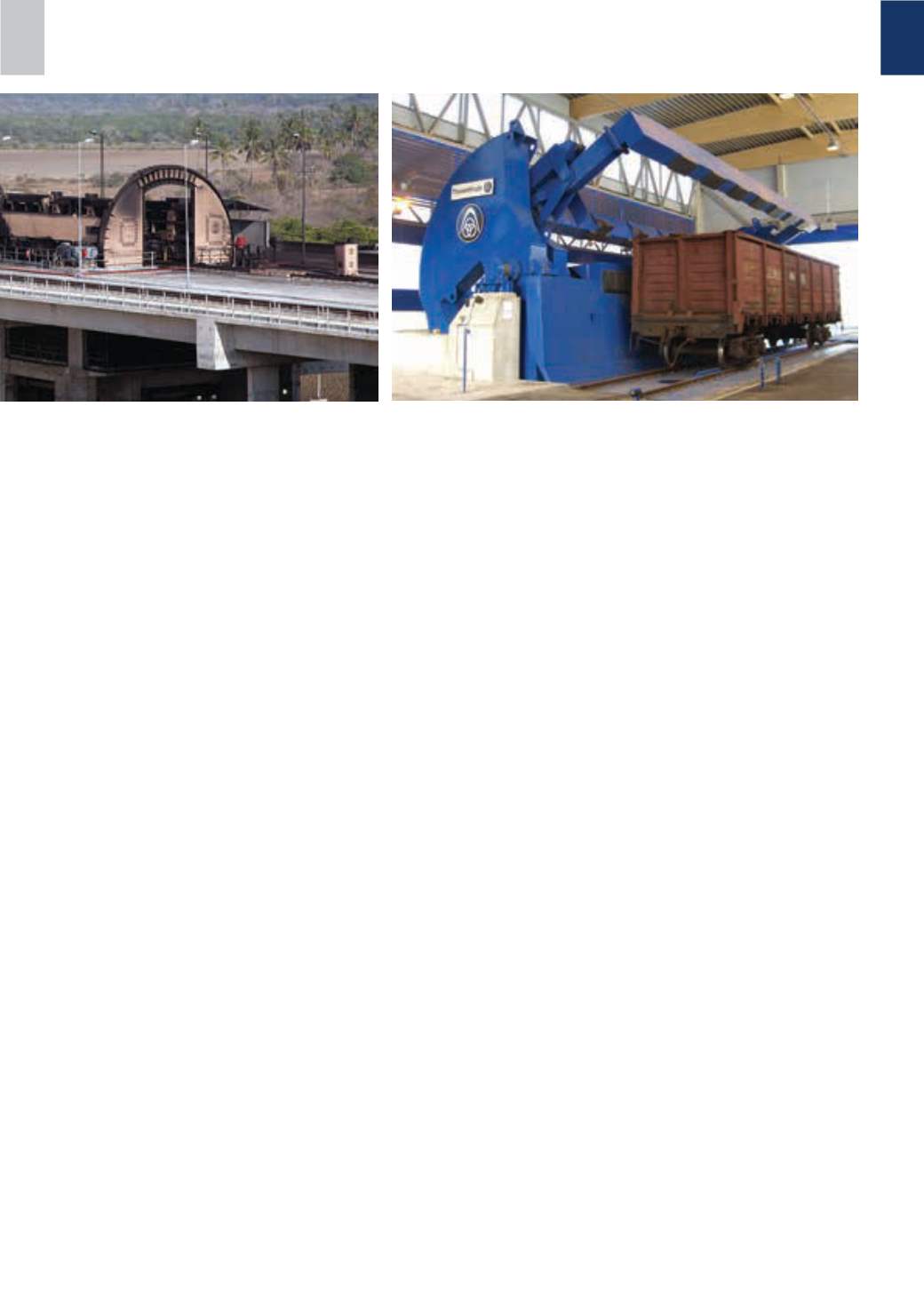

Left:

Rotary tipplers are designed so that the turning point coincides with the axis of

rotation of the wagon couplings in the tippler.

Right:

Side tipplers are the simplest random tippler option.