32

Mechanical Technology — January 2015

⎪

Innovative engineering

⎪

E

stablished in 2009 in UKZN’s

Mechanical Engineering de-

partment, Brooks says aero-

space research is not new to

the university and that Natal University

had been active in the field since the

1950s. “We chose the name Phoenix to

reflect the resuscitation of a programme

started by our predecessors,” he says.

The Phoenix research programme

involves the development of a series

of hybrid sounding rockets, for human

capital development purposes and,

eventually, for use by the African sci-

entific community for physics research.

Following successful lab-scale tests on

wax/nitrous oxide rocket motors – along

with the development of HYROPS, a hy-

brid rocket performance simulator that

models rocket performance and flight

paths – the group set about designing

and making its Phoenix-1A, a hybrid

rocket with a theoretical apogee of

10 km, capable of delivering a payload

of 1.0 kg.

“A sounding rocket is a high‑at-

mosphere, instrument-carrying rocket

designed to take measurements and

perform scientific experiments during

a relatively short sub-orbital flight,”

Brooks explains, adding that hybrid

motor technology is ideal for these

types of applications and for student

development.

Describing the three basic types of

rocket motor, he says that liquid propel-

lant technology is used for the larger

rockets. Typically these have a tank of

liquid oxygen and a separate tank of

a fuel such as kerosene. The fuel and

the oxidiser are mixed and ignited to

create the expanding combustion gases

that produce the rocket’s thrust. “The

hardware required to pump the oxidiser

and fuel is very complicated, expensive

and heavy. And it is dangerous to use

these fuels at institutions such as uni-

versities,” he says. “Liquid technology

does not scale well, either, so it is not

really feasible for small-scale sounding

rockets.”

At the opposite end of motor tech-

nology are the solid-fuel rockets that

are, in essence, similar to those used

for fireworks. “With solid-fuel rockets,

the combustion fuel and oxidiser are

mixed in advance, then packed into

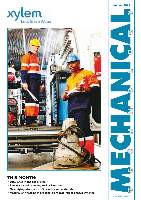

Phoenix hybrid sounding rocket launched

Under development, UKZN’s aerospace Group’s Phoenix-1A, a hybrid rocket with a theoretical apo-

gee of 10 km, capable of delivering a payload of 1.0 kg.

The Phoenix-1A hybrid sounding rocket

immediately prior to launch at the

Overberg Test Range.

During August last year, the Aerospace Systems Research Group of

the University of KwaZulu-Natal (UKZN) launched its Phoenix-1A

hybrid sounding rocket at the Denel Overberg Test Range.

MechTech

talks to Michael Brooks, aerospace research group leader (right of

picture) and research associate Jean Pitot.

the rocket’s combustion chamber. From

the moment you ignite it, the motor will

burn, and it can’t be stopped until all

the fuel is spent. As with liquid technol-

ogy it is very difficult to do solid motor

research at a university because the fuel

is explosive and, therefore, dangerous,”

Brooks points out.

Hence the use of hybrid rocket mo-

tors. “A hybrid rocket uses a solid plas-

tic, rubber or wax fuel and a separate

liquid or gaseous oxidiser. The fuels

are not premixed,” says Brooks. The

solid fuel UKZN is using is a cylinder

of paraffin wax – Sasol 0907, a mix of

saturated, long-chain alkanes – with a