CONTROL SYSTEMS + AUTOMATION

ROUND UP

Collaboration creates single platform for electrical engineering solutions

Schneider Electric

, the global specialist in energy management

and automation, has stated that Eplan is its major E-CAD solutions

provider to design the products of its energy division on a global

scale. Eplan Platform enables Schneider Electric to optimise its

complete workflow from design to production.The solution helps to

structure and to centralise the components' database and facilitate

knowledge management. All the know-how is embedded, up-to-date

and available for each entity.With Eplan Platform, Schneider Electric

plans to significantly increase productivity by standardising all the

components and reusing them.

“For a long time, each entity of Schneider Electric’s Energy Division

across the world has worked with its own tools and implemented

specific design processes, explains M Frédéric Abbal, Executive

Vice-President, Energy division at Schneider Electric.With the imple-

mentation of Eplan Platform, Schneider Electric expects to centralise

its know-how, enhance collaboration between sites and balance

workload according to the different projects.”

Haluk Menderes, Managing Director Eplan, adds: “The combina-

tion of our 30 years of experience in engineering solutions and the

know-how of one of the worldwide largest player in the energy

domain will bring the best in class processes and a greater electri-

cal engineering and manufacturing efficiency to Schneider Electric.”

Enquiries: Ntombi Mhangwani.Tel. 011 254 6400 or

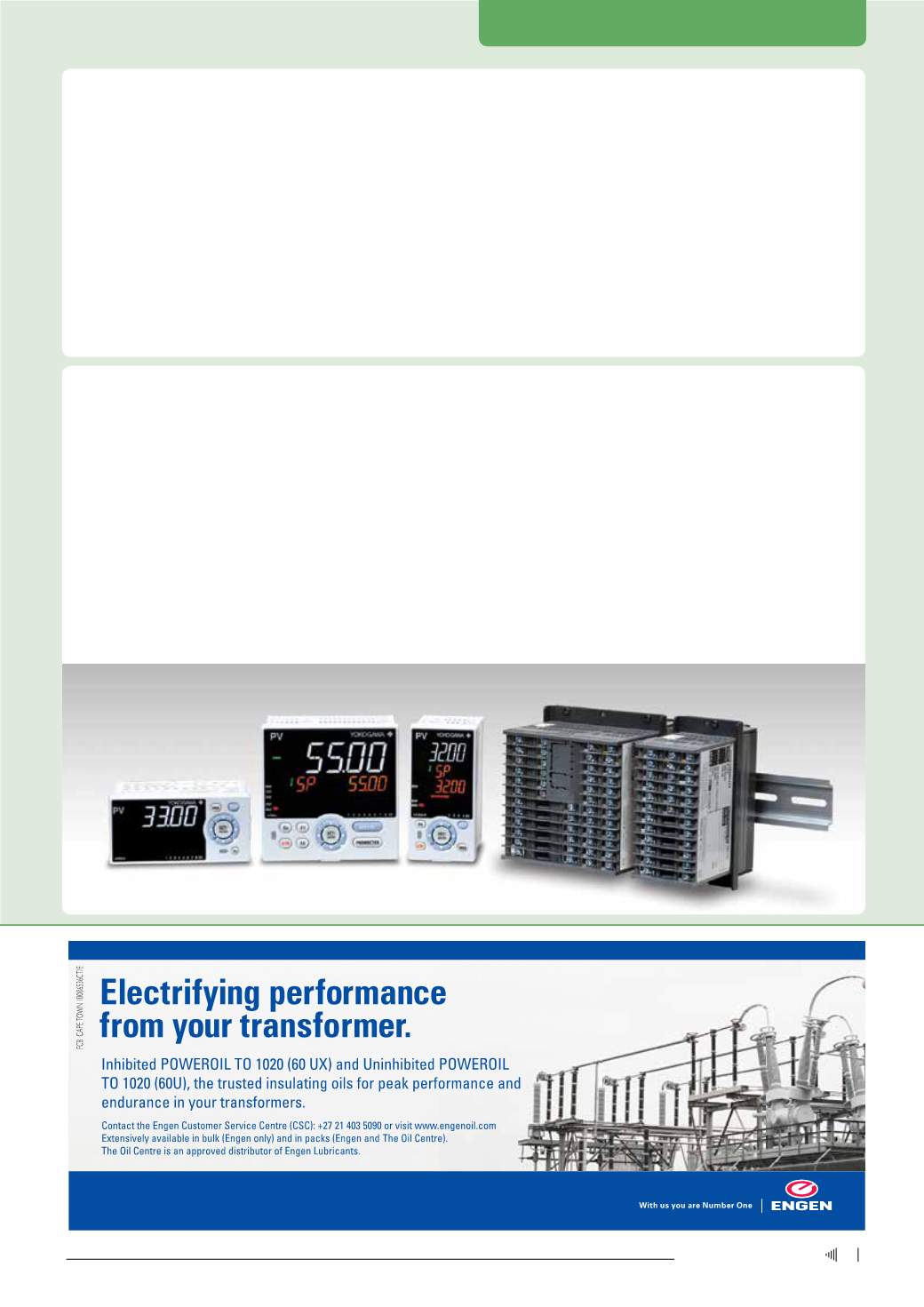

New controllers for heat-process industry

Yokogawa Electric Corporation

has released a number of new

UTAdvanced series controllers including four DIN rail 1 mounting

type controllers and one 1/8DIN panel type program controller.This

is part of Yokogawa’s ongoing effort to expand its controller busi-

ness by satisfying market needs and giving customers a greater

range of choices.

UTAdvanced series controllers are mounted on furnaces and other

types of heat process-related industrial facilities for the measure-

ment, display, and control of operating variables such as temperature,

pressure, and flow rate. In recent years, it has become more common

for equipment manufacturers to integrate the setting, manipulation,

and display functions of programmable logic controllers (PLC) and

other embedded control devices on touch panels and other types

of user interfaces, and to mount the hardware on DIN rails inside

panel boxes.There is an increasing need for such DIN rail mounting

type controllers.

The UTAdvanced series controllers come in two sizes: 1/4 DIN and

1/8 DIN. While 1/4DIN controllers are more popular because they

have large display panels and provide a wider range of I/O signal

choices, there are certain applications where space is at a premium

that require a smaller device. For just such applications, Yokogawa

has added more 1/8DIN controllers to its product line-up.

The UTAdvanced controller comes standard with a sequence

control function based on the ladder logic programming language,

which is widely used by engineers.

Enquiries:Tel. 011 831 6300 or email

Christie.cronje@za.yokogawa.com7

June ‘15

Electricity+Control