Industry News

www.read-tpt.com8

S

eptember

2015

Lincoln Electric supports aspiring

engineers

A WELDING technology company

and the son of its founder have joined

resources to support the work of an

innovative welding engineering training

scheme in the USA.

With a $1mn donation, Cleveland,

USA-based Lincoln Electric and

David Lincoln have co-funded the first

endowed professorship in welding

engineering at The Ohio State

University. Lincoln Electric also donated

or consigned nearly $420,000 worth of

welding equipment and technology for

use by Ohio State students and faculty.

A cornerstone of Lincoln Electric’s

success has been welding engineering

expertise and product innovation,

according to Christopher L Mapes,

Lincoln Electric’s chairman, president

and chief executive officer.

“The endowment at Ohio State

honours that legacy and places Lincoln

Electric at the forefront of welding engi-

neering education. It also underscores

our commitment to develop future

welding experts who will continue to

drive innovation in our industry.”

Founded in 1895 by John C Lincoln,

an Ohio State electrical engineering

alumnus (1888), Lincoln Electric is

a global provider of comprehensive

arc welding, cutting and joining

solutions. David Lincoln is a successful

entrepreneur and philanthropist. He

founded the Lincoln Laser Company

and a real-estate business in Phoenix,

Arizona, USA.

Residing in the Department of

Materials Science and Engineering,

the endowed welding engineering

professorship will facilitate recruitment

of a new faculty member during the

2015-2016 academic year.

“Gifts that support our programmes

and students are extra special when

they originate from the family of a

distinguished alumnus like John Lincoln

and the company he established,” said

College of Engineering Dean David B

Williams. “Lincoln Electric and David

Lincoln are steadfast in their belief that

education drives innovation.”

Welding equipment provided by

Lincoln Electric will benefit more

than just the welding engineering

programme. Students and faculty in

mechanical and aerospace engineering,

integrated systems engineering and

agricultural engineering will also use the

latest arc welders, training simulators,

fume extraction units, plasma cutters,

software and safety equipment.

Additionally, manufacturing research

collaborations and partnerships will

utilise the new technology.

Lincoln Electric is a leading company

in the design, development and

manufacture of arc welding products,

robotic arc welding systems, plasma

and oxy-fuel cutting equipment, and

has an established global position in

the brazing and soldering alloys market.

It has 47 manufacturing locations,

including operations and joint ventures

in 19 countries and a worldwide network

of distributors and sales offices covering

more than 160 countries.

A former Lincoln Electric board

member, David Lincoln is the chairman

of the Claremont (CA) Lincoln University

and served on the board of the

Claremont School of Theology for a

number of years.

Ohio State’s welding engineering

programme is the only ABET-accredited

undergraduate programme in North

America. It also offers master’s and

doctoral degrees, including a nationally

ranked online master’s option.

Lincoln Electric

– USA

Website:

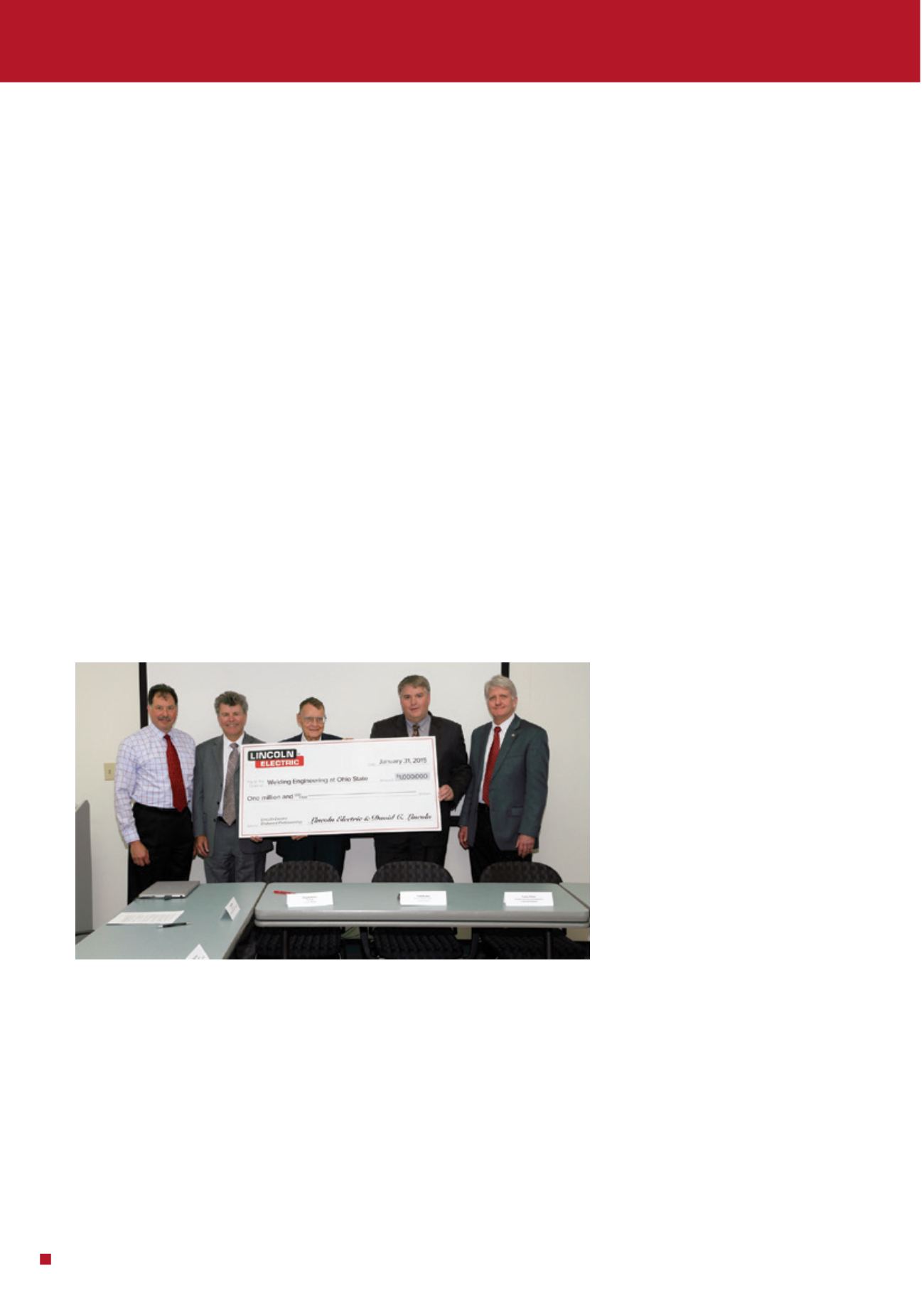

www.lincolnelectric.com(left to right) Prof John Lippold, Dean David B Williams, David Lincoln, Lincoln Electric North

America president George D Blankenship, and Prof Mike Mills

Copper tube plant equipment sale

MACHINERY International Corporation,

USA, has been awarded a contract to

sell the machinery and equipment of

the Crane Copper Tube Plant located

in Sydney, Australia.

The sale will include a Schumag

3 draw cascade line, 3,500-ton BLH

extrusion press, four spinner blocks,

four drawbenches, and a large quantity

of finishing lines.

The company was also recently

awarded a contract to sell the assets of

the Profil Desnoyer Copper Tube Plant

in Tunis, Tunisia.

This sale includes six Schumag

lines, MRB spinner blocks, a 1,600-

ton press, a complete copper tube

fittings department, and several large

drawbenches.

Machinery International Corp

– USA

Fax: +1 203 484 4499

Email:

sales@machyintl.comWebsite:

www.machyintl.com