Cutting, sawing & prof i l ing technology

www.read-tpt.comS

eptember

2015

111

Numalliance continues

growth with EMS deal

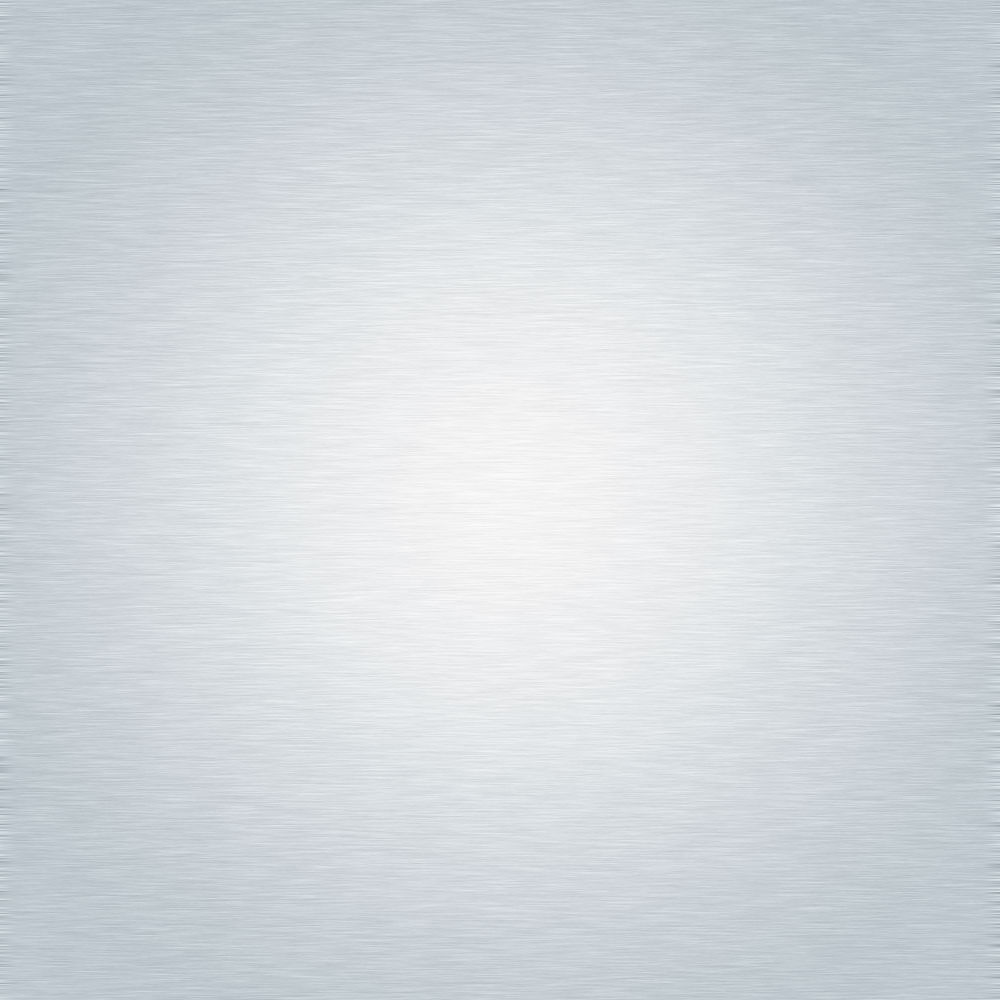

NUMALLIANCE, a manufacturer of CNC

cold forming equipment for wire, tube,

flat-stock and spring, has announced the

purchase of EMS (Electro Mécanique

Saverne). EMS specialises in the design

and production of machines for chip-

less end forming, and rotary and blade

cutting machines for tubes.

With this new acquisition Numalliance

extends its offering in tube processing

for various industries. The solutions

offered by Numalliance are used for

automotive (seating frames, exhaust),

point of purchase (supermarket carts,

display shelves), furniture, agriculture

applications and more.

Numalliance was the result of a

merger of three companies: Macsoft,

Latour and Satime. The company’s

strength is in its mechatronic expertise:

the hybridisation of mechanics and

the in-house development of its user-

friendly software. In October 2013

Numalliance integrated Silfax, an expert

in tube bending with a strong foothold in

the aeronautics industry.

EMS will benefit from the support of

Numalliance’s subsidiaries based in

China, Germany, India, Mexico, USA and

Slovakia,andalsoitsinternationalnetwork

of sales agents and sales engineers.

Numalliance generates more than 92

per cent of its sales outside France and

50 per cent outside Europe.

“With this acquisition, we keep extend-

ing our competences to offer our custom-

ers a global and fully integrated answer

to their needs with complementary and

compatible products,” said Joël Etienne,

CEO of Numalliance. “The addition of

EMS perfectly fits our company’s dynam-

ic motion and constant evolution. We set

our business internal and external growth

target high for the year to come.”

Numalliance

– France

Website:

www.numalliance.comEMS

– France

Fax: +33 3 8891 0537

Email:

info@ems-sa.comWebsite:

www.ems-sa.comShear blade

coating for

stainless

steel tube

HAVEN Manufacturing Corporation, in

co-operation with Tru-Cut Saw Inc, has

introducing a new cross-cut and shear

blade coating that improves blade life

when cutting austenitic stainless steels.

The new nano-composite PVD coating

that Tru-Cut Saw is using to increase the

life of circular saw blades is now available

for trial to Haven customers for their dual-

blade shear blades. The new coating,

called ViTA-Nano and developed by Tru-

Cut’s ICO Surface Coatings Division, is

a proprietary combination of titanium,

aluminium, aluminium-titanium, chrome

and silicon. Unlike multi-layer coatings

in which each material is deposited

consecutively, with ViTA-Nano all

cathodes in the PVD chamber are turned

on at once. This reportedly results in a

more cohesive, harder coating.

Haven Manufacturing Corp

– USA

Email:

sales@havencut.comWebsite:

www.havencut.comThe new coating from Haven and Tru-Cut saw