38

nols, cresols, naphthalene, anthracene and complex organic

compounds such as polycyclic aromatic hydrocarbons (PAH).

Water is also used as a lubricant in industrial machinery and

can become contaminated with hydraulic oils, tallow, tin, chro-

mium, ferrous sulphates and chlorides and various acids.

Industry has a primary responsibility to reduce the production

of toxic waste. Many incentives are based on voluntary mea-

sures, but governments and the public sector must play a cen-

tral role in monitoring, regulating and also implementing pol-

icy to reduce toxic waste. Industrialized nations have generally

recognized that in theory it is simpler and more cost-effective

to deploy cleaner production processes than to clean up large-

scale industrial pollution. Pollution from wastewater depreci-

ates land values, increases municipal costs and causes numer-

ous adverse biological and human health effects, the cost of

which are difficult to calculate.

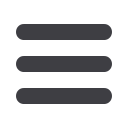

Figure 13:

Mining effects on rainfall drainage. Acid Mine Drainage (AMD) is

the number one environmental problem facing the mining industry. AMD occurs

when sulphide-bearing minerals in rock are exposed to air and water, changing

the sulphide to sulphuric acid. AMD can devastate aquatic habitats, is difficult to

treat with existing technology, and once started, can continue for centuries (Ro-

man mine sites in Great Britain continue to generate acid drainage 2 000 years

after mining ceased (Mining Watch Canada, 2006)).

In many countries the responsibility for industrial wastewater

treatment falls on ordinary taxpayers. In the absence of a user-

pays system for pollution control, large volumes of contami-

nated industrial wastewater end up in municipal sewage treat-

ment plants, which are expensive to construct, operate and

maintain. The Netherlands introduced a series of incentives

to polluters to reduce pollution at source, rather than opting

for the more expensive end-of-pipe solution of public sewage

treatment. This approach has been cost-effective in reaching

water quality targets (the Urban Waste Water Treatment Di-

rective). In contrast other European member states who have

not introduced a polluter-pays system or have been slow to

adopt one have consequently not reached targets (e.g. France)

or have paid a high price to do so (e.g. Denmark)(EEA, 2005).

The problem of poor water quality in many urban centres has

been one of the factors that have lead those who can afford it

to turn to bottled water. Bottled water sales worldwide have

increased rapidly with global consumption now at more than

200 000 million litres a year. While the USA is the biggest

consumer of bottled water, China has shown the strongest

growth, increasing consumption by more than 15 per cent

since 2003 (Beverage Marketing Corporation). The cost of

producing bottled water is a serious concern. In the United

States it is estimated that the production of the bottles alone

requires 17 million barrels of oil a year and it takes three litres

of water to produce one litre of bottled water

(Source: Pacific Institute

http://www.pacinst.org/topics/water_and_sustainability/bottled_water/bottled_water_and_energy.html)

How to get industry to clean up its act?

Bottled water

After Mining

Filtering soils

Groundwater

Surface runoff

Mine

Sulfide

OXYGEN + WATER + SULPHIDE = SULFURIC ACID

Heavy Metals Fish Mortality

Filtering soils

Groundwater

Rainfall filtering

through soil

Surface runoff

Before Mining

Sulfide

Extraction decreases groundwater depth and

natural filtration, and increases the

groundwater contamination.