1/2

1

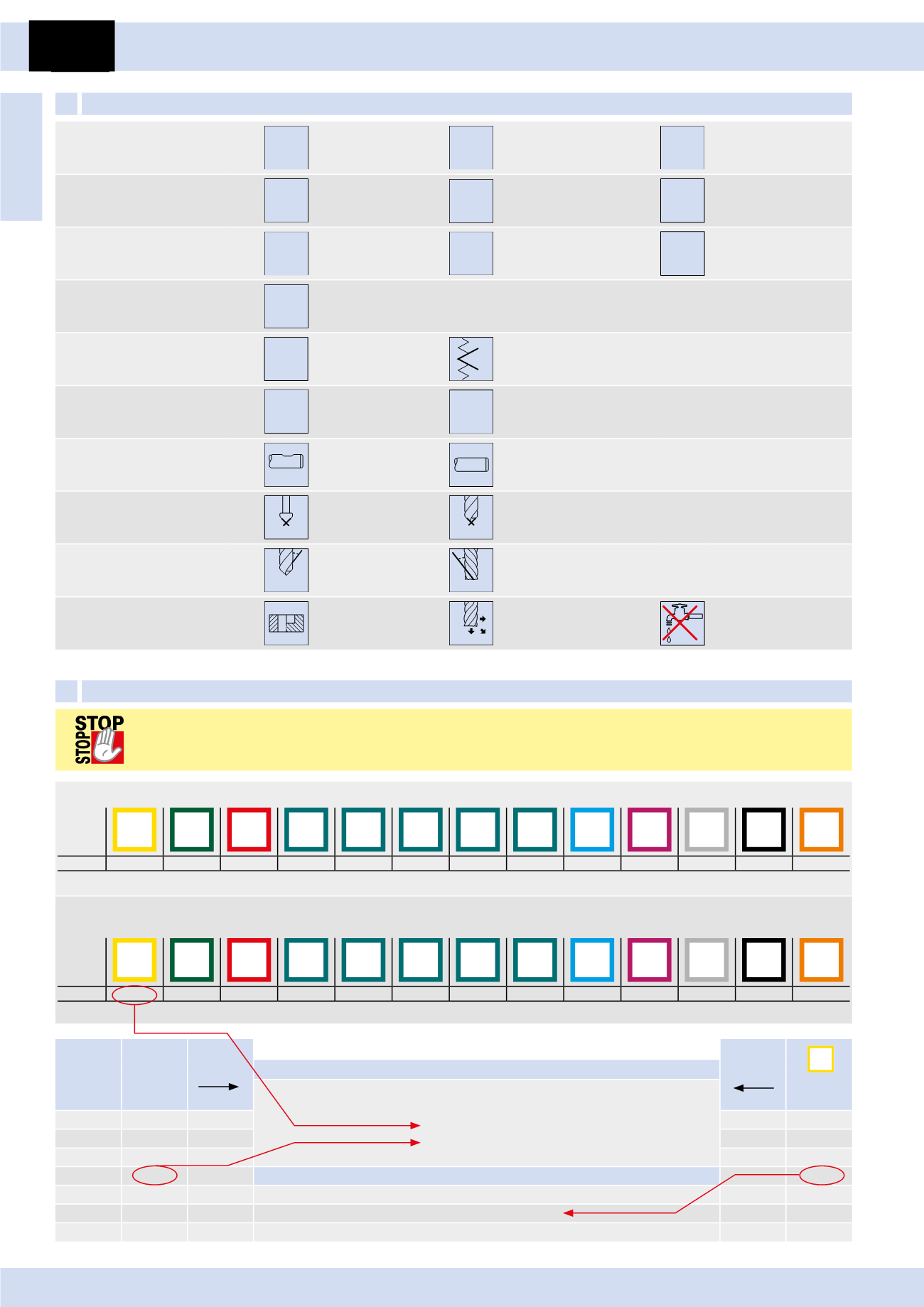

Cutting Tools

Pictogram Abstracts

Tool material

e. g.

HSS

High-speed

HSS

HSS

Co5

HS steel with 5 %

Cobalt alloy content

VHM

K10/

K20

Solid carbide -

Sort K10/K20

Standard

e. g.

DIN

208-B

Equiv. to DIN 208

Form B –

Spiral fluted

DIN

338

Equiv. to DIN 338

EN

22568

Equiv. to

European

standard 22568

Type

e. g.

Type

N

Machining of materials

with normal

resistance and hardness

Type

W

Machining of materials with

low resistance and hardness

Type

H

Machining of materials

with higher

resistance and hardness

Number of cutting

edges

e. g.

Z

4

Number of teeth 4

(4 cuts)

Thread

e. g.

M

Metric thread

60°

with edge angle 60°

Tolerance

e. g.

H7

Tolerance zone H7

ISO 2

6H

Metric ISO threads/FORUM

Usage class 2

Medium tolerance 6H

Shaft design

e. g.

DIN

1835-B

Cyl. shaft with

Carrier surface

acc. to DIN 1835 B

Cylinder shaft

Point angle

e. g.

90°

Countersink with

90° Point angle

130°

Spiral drill 130° Point angle

Spiral angle

e. g.

25–30°

Right spiral

with 25° to 30° angle

ca. 7°

Left spiral with

ca. 7° angle

Application

e. g.

for through

and blind holes

Feed directions

Dry machining possible

All information regarding cutting speed and feed rate correspond to a recommended guideline.

This requires stable machine conditions, a low-vibration workpiece and the use of a suitable coolant.

Symbol mapping

Order

No.

Steels

up to

850

N/mm

2

Steels

up to

1000

N/mm

2

Steels

up to

1400

N/mm

2

Steels

up to

42 HRC

Steels

up to

52 HRC

Steels

up to

56 HRC

Steels

up to

60 HRC

Hard

processing

over

60 HRC

Stainless

and acid-

resistant

steels (INOX)

Ti steels,

Ti alloys,

special

steels

Cast iron

materials

Al, Al- and

Mg alloy

Copper,

brass,

bronze

1040

C

C

C

C

C

U

C

V

C

C

recommended

U

suitable

V

limited suitability

Mapping of values

Cutting speed V

c

Order

No.

Steels

up to

850

N/mm

2

Steels

up to

1000

N/mm

2

Steels

up to

1400

N/mm

2

Steels

up to

42 HRC

Steels

up to

52 HRC

Steels

up to

56 HRC

Steels

up to

60 HRC

Hard

processing

over

60 HRC

Stainless

and acid-

resistant

steels (INOX)

Ti steels,

Ti alloys,

special

steels

Cast iron

materials

Al, Al- and

Mg alloy

Copper,

brass,

bronze

1040

35

35

25

25

19

30

30

50

35

Font bold = recommended

Font normal = suitable

Order

No.

∅ h8

mm

etc.

Example calculation (Spiral drill 4.0 mm, mild steel up to 850 N/mm

2

)

etc.

6WHHOV

XSWR

1PP

f

mm/rev

Value sought 1

:

n =

number of revolutions per minute (r/min)

Formula:

n =

V

c

x 1000

__________

D x ∏

Calculation:

n =

35 m/min x 1000

__________________

4.0 mm x 3.14159

Solution:

n =

2785/min

0101

1.0

0.090

0102

2.0

0.095

0103

3.0

0.10

0104

4.0

Value sought 2:

v

f

=

feed rate (mm/min)

0.105

0105

5.0

Formula:

v

f

=

n x f

0.11

0106

6.0

Calculation:

v

f

=

2785/min x 0.105mm/rev

0.115

etc.

etc.

Solution:

v

f

=

292 mm/min

etc.

Cutting speed and feed rate

Pictograms and Cutting Data

22