1/6

1

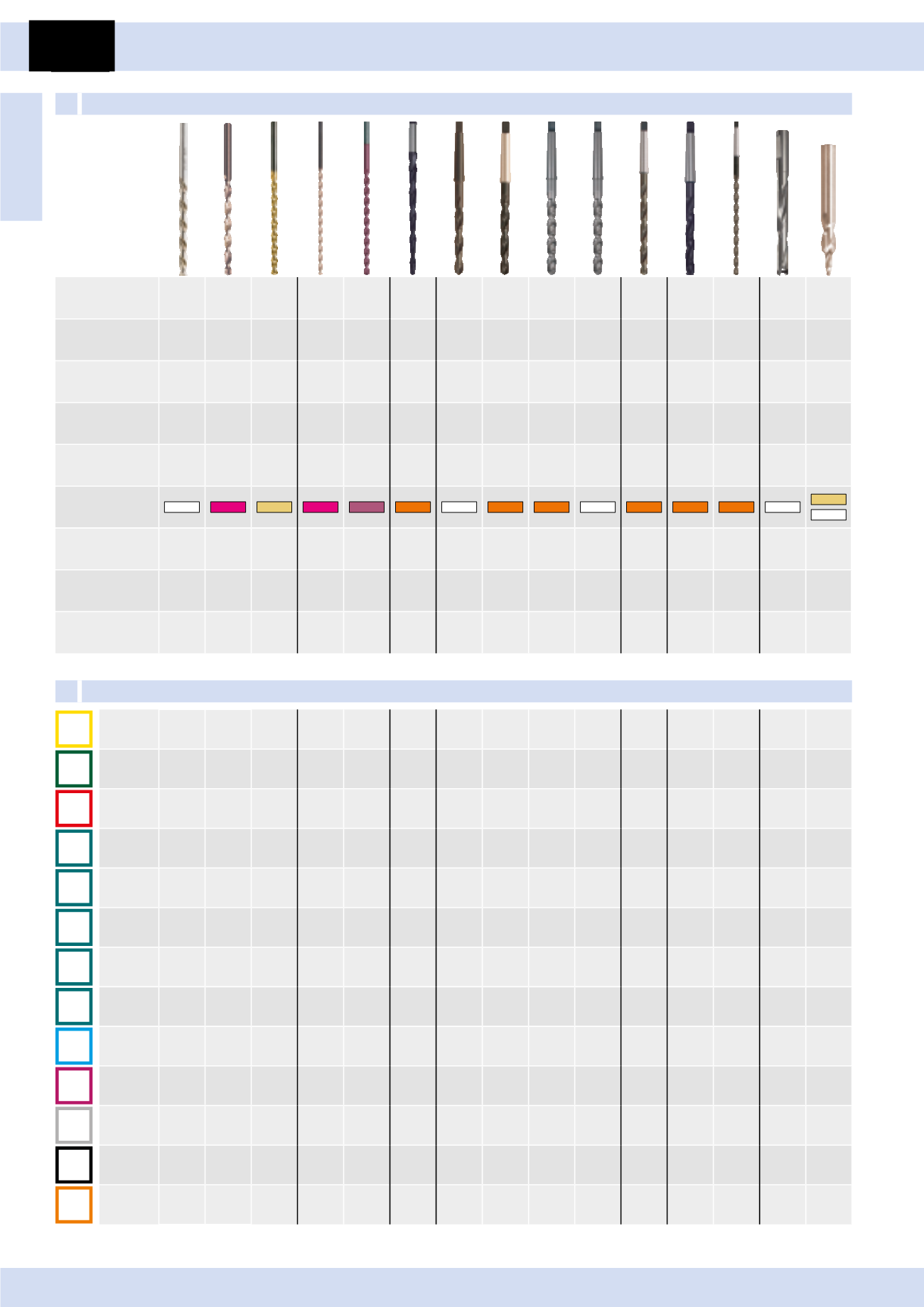

Cutting Tools

Order No.

1047 1051 1053 1067 1071 1052

1083 1080 1081 1082 1089 1085 1092

1091–

1096

1100–

1107

∅ mm from–to

1–13 1–13 1–13 3–12 3–12 2.5–12 10–50 10–50 10–50 10–34 10–50 7.8–30 8–30 16–40 M3–M12

DIN

340 340 340 1869 1869 1898/1 345 345 345 345 341 343 1870

factory

standard

Material

HSS Co5 HSS Co5 HSS Co5 HSS HSS Co5 HSS

HSS

roll forged

HSS HSS HSS Co5 HSS HSS HSS

VHM

(plate)

HSS

Drill type

Ti

TF

GU500 TF

TF

N

N

N

N INOX

N

N

TF

N

Coating

bright

Nitrated

TiN

Nitrated

TiAlN

steam bright

steam steam bright

steam steam steam bright

TiN

bright

Point angle

130°

130°

118°

130°

130°

118°

118°

118°

118°

130°

118°

120°

130°

140°

118°

Thinning

A

A

A

A

A

A

A

A Special

A

Page

1/34 1/35 1/35 1/36 1/36 1/32 1/37 1/38 1/38 1/39 1/40 1/40 1/41 1/42 1/46

Steels

up to

850

N/mm

2

U C C U C C C C

U C C

C

Steels

up to

1000

N/mm

2

C U

C U

U

U

Steels

up to

1400

N/mm

2

C U

C

U

Steels

up to

42 HRC

C U U C

U C

Steels

up to

52 HRC

U

U

Steels

up to

56 HRC

Steels

up to

60 HRC

Hard

machining

over

60 HRC

Stainless

and acid-

resistant

steels (INOX)

U C U

C

C

C

Ti steels,

Ti alloys,

special

steels

C

C

U

Cast iron

materials

U C C

C

U U

U

C C U

Al,

AI and

Mg alloys

C

U

C

U

C

Copper,

brass,

bronze

U C

U

U

U

C

recommended

U

suitable

V

limited suitability

Material group

Overview – HSS spiral drill programme

Drilling tools

26