August 2016

AFRICAN FUSION

7

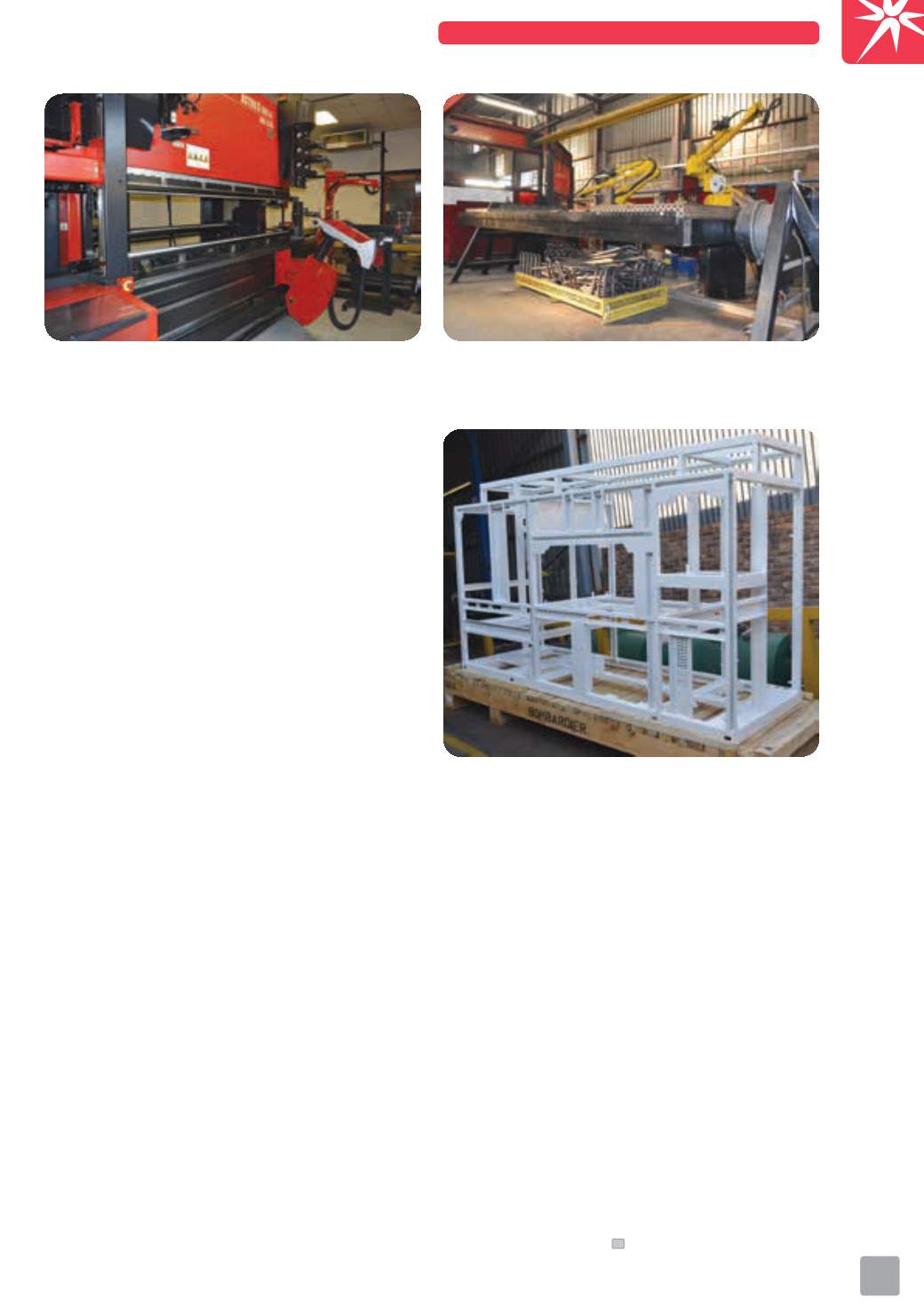

SPE’s AMADA Astro robotic bending system has a 130 t capacity along

a 3 000 mm length. The system’s robot picks up a part, measures it and

then transfers it to a manipulator on the bending brake, where the part

can be repositioned as many time as necessary to compete the bending

processes.

To support the higher volume parking systems’ work, welding assembly

is supported by three Fanuc/Lincoln electric robotic welding systems:

a two-robot cell that includes a 4.0 t manipulator and two multi-axes

turntables and a second robot for sub-component assembly.

SPE is currently fabricating high voltage cubicles and traction converter

cabinets for South Africa’s railway rejuvenation projects.

procedures and then training them to

do what needs to be done.”

In keeping with its belief in state-

of-the-art machine tools, welding as-

sembly is supported by three Fanuc

robotic welding systems. The largest is

a two-robot cell that includes a 4.0 t ma-

nipulator and twomulti-axes turntables.

A second Fanuc robot is employed as a

sub-component assembly station. Both

systems use Lincolnwelding equipment

and are supported by Pretoria-based

Robotic Innovations.

“The robot system is used exten-

sively for our ongoing parking systems’

work. The two-robot cell welds the fin-

gers that rise up from the ground at the

boom gates to prevent non-payment.

The turntable allows the whole part to

be rotated for better access to all of the

welding required. Boomgates and park-

ing system consoles have long been our

flagship capability andwemanufacture

these for a number of different OEMs,”

says Diedericks.

“On the manual side, we use mostly

theMIG/MAGwelding processwith some

TIGwelding.We alsohave five spotweld-

ing machines and a stud gun,” he adds.

Returning to welding quality man-

agement issues, Diedericks says the

quality at source approach runs through

every aspect of component manufac-

ture. “On the welding side, we do a

before, during and after inspection, with

our welding inspector taking primary

responsibility. Then, after grinding, we

apply a visual inspection and sign-off

stage to 100% of the assemblies.

Since very early in its inception, SPE

has been ISO 9001-certified, but since

Diedericks’ arrival, ISO 3834 certifica-

tion has been implemented to further

enhance the quality and creditability of

the company on the

welding side.

“Our ISO 3834

welding quality sys-

temwas built fromthe

ground up, with pro-

cedure development

and training at the

root of implementa-

tion. It was a mindset

change for the fabrica-

tion team on the shop

floor, to first look for

the procedures that

applied to the job and

then to routinely apply

them. On the other

hand, welders had to

get used to not doing

any work that they

were not yet qualified for.

“Our welders were willing to learn,

though, and they applied the new

system with enthusiasm. The whole

team has gone out of its way to make

ISO 3834 work for us, to improve weld

quality and production performance,”

Diedericks notes.

“Quality gives us a competitive

advantage: We now offer excellent

quality on the welding side and this is

appreciated by management and cus-

tomers, resulting in new contracts and

in significant growth. So much so that

we are having to extend the workshop

space to accommodate the additional

work,” he adds.

Due to the significant increase in

railway contracts being awarded to

SPE, the company is also gearing up

for ISO 15085-accreditation for the

manufactureof railway components and

structures. “We are currently involved

with Bombardier, fabricating high volt-

age cubicles and traction converter

cabinets for one of the SouthAfrican rail-

way rejuvenation projects. We are also

making the frames for 2.0m locomotive

radiators for a railway sub-contractor

and, in aluminium, we have started to

fabricate the driver control panels for

railway climate control solutions,” Die-

dericks reveals.

“We are aiming to become a railway

specialist, hence the need for ISO15085.

We expect to be audited during August

andwehope tobeCL2-accreditedbefore

the end of this year,” he tells

African

Fusion

.

“SPE is constantly striving for prod-

uct excellence by keeping up-to-date

with the latest technologies and trends

in the sheet metal Industry. We guaran-

tee excellent service to all our clients

with timeously delivered, quality-

inspected goods that are certified to

international quality standards,” he

concludes.

SAIWmember profile: Stainless Precision Engineering