August 2015

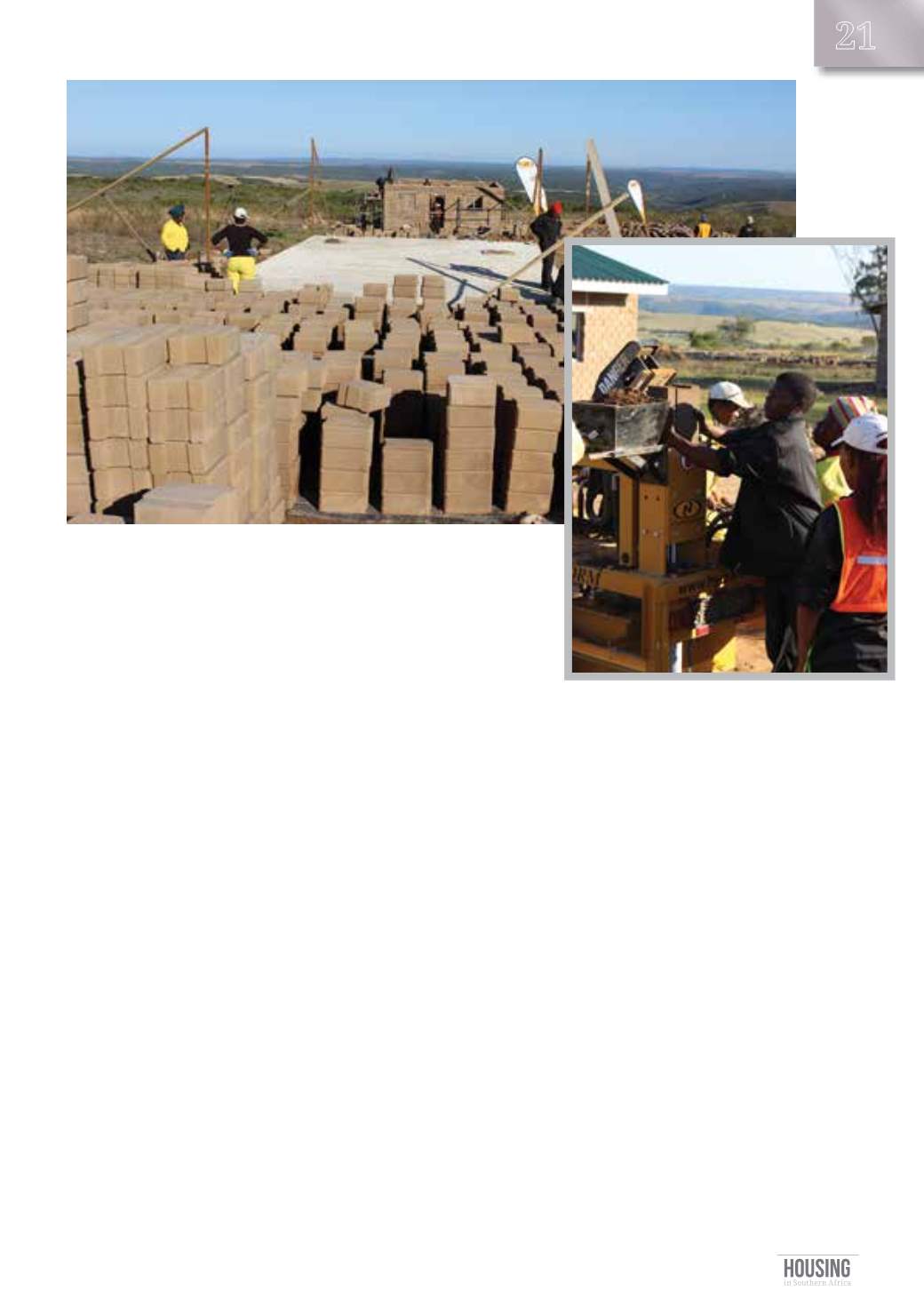

Energy Efficiency, Green Building & IBTs

T

he Department of Rural De-

velopment and Land Reform

initiative at Radway Green

Farm, outside Grahamstown, pro-

vided housing for the local commu-

nity using Hydraform’s block-making

machinery.

The turnkey project enabled the

local community to participate in the

rural build and learn new skills.

Nazlie Dickson, Sales and Mar-

keting Director of Hydraform says,

“Hydraformblock-makingmachinery

provides smart solutions to the logis-

tical challenges presented by a rural

or peri-urban build, and due to its

innovative dry-stacking method, the

final product has a lower embodied

energy than traditional bricks and

blocks.”

Dickson comments: “Hydraform

blocks are not baked or fired, which

saves a remarkable amount of en-

ergy. The dry-stack interlocking tech-

nology also saves construction time

and cement costs as well as providing

materials with less embodied energy,

contributing to a structure that is

greener overall.”

The Radway Green Farmproject is

a self-sustainable, independent de-

velopment that includes solar power,

a waste management system as well

as water delivery.”

She continues, “A key objective of

the project was to ensure that the

community members were not only

beneficiaries of homes, but that they

were trained in block-making and

construction as part of their skills de-

velopment. The communityproduced

150 000 blocks that went into build-

ing their houses. Our products are

able to work around infrastructural

constraints and still deliver housing,

community centres, health facili-

ties and schools – even in the most

remote areas. The Radway Green

project began in March 2015 and will

be completed by August 2015 – on

time and within budget.”

While the project houses a number

of families, it also showcases Hydra-

form’s projectmanagement skills and

unique technologies that are well

suited to local housing delivery.

“Projects like this prove that we

are able to adapt to market needs,

and in this case, the affordable hous-

ing market, by providing specialised

and dynamic turnkey housing deliv-

ery options. This extended offering

meanswemakemeaningful contribu-

tions to South Africa’s job creation,

skills development and community

upliftment objectives,” says Dickson.

Hydraform’s block-making ma-

chinery was transported to site,

ensuring a good quality product that

didn’t have to travel far to get to its

destination, which cut down tremen-

dously on transportation costs and

rendered the product more inher-

ently energy efficient.

The Radway Green Farm project

also offered a unique set-up to test

out the versatility and robust nature

of the machinery. Notes Dickson,

“The project itself is in a rural set-

ting where there is no formal water

and power facilities or supply. But

this made no difference to the per-

formance of our machinery, which is

highlymobile and canproduce blocks

on site,” concluded Dickson.

Hydraform has 25 years of ex-

perience in alternative building

technologies. Through continuous

research and development with lead-

ing institutions, the company has

developed a dry-stack interlocking

building block, eliminating the use of

mortar in 70% of the building struc-

ture. There is no need for concrete or

steel columns and this offers a cost

effective housing solution and qual-

ity product. For further information

contact Hydraform on 011 913 1449

or email:

sales@hydraform.com■

Eastern Cape housing

South African brick-and-block making machinery leader,

Hydraform, has contributed to the construction of low income

housing in the Eastern Cape.