standard solution and 2 g ISTD standard solution into a 50

mL flask. Dilute to volume with water and accurately weigh

the solution. Cap and mix well. Transfer to an autosampler

vial and cap.

(

5

) Level 5 calibration standard. - Accurately weigh 26 g

standard solution and 2 g ISTD standard solution into a 50

mL flask. Dilute to volume with water and accurately weigh

the solution. Cap and mix well. Transfer to an autosampler

vial and cap.

(

6

) Level 6 calibration standard. - Accurately weigh 40 g

standard solution and 2 g ISTD standard solution into a 50

mL flask. Dilute to volume with water and accurately weight

the solution. Cap and mix well. Transfer to an autosampler

vial and cap.

F. Sample preparation and Extraction

(

a

)

Sample weighing. –

(

b

) Accurately weighed the extraction vessels.

(

1

) For dry blended/nonhomogeneous powder samples,

transfer 25 g, accurately weighed to a 250 mL volumetric

flask. Dissolve using warm distilled water ~40°C, cool, and

make up to 250 g accurately weighed with distilled water.

Transfer 10 - 15 g accurately weighed of reconstituted sample

to the extraction vessels.

(

2

) For wet blended homogeneous powder samples, transfer 2

- 3 g, accurately weighed directly to the extraction vessels.

(

3

) For ready-to-feed samples or concentrated liquid

products, transfer 5 to 10 g, accurately weighed of thoroughly

agitated sample directly to the extraction vessel.

(

4

) For dry food or animal feed samples, transfer 5 - 10 g,

accurately weighed of sample directly to the extraction

vessel.

(

5

) For wet food or animal feed samples, transfer 10 - 15 g,

accurately weighed of sample directly to the extraction

vessel.

(

6

) For nutritional supplements, transfer 1 – 1.5 g, accurately

weighed of sample directly to the extraction vessel.

(

c

) Ekstraction. –

(

1

) For liquid samples no added water is necessary. For wet

samples add 5 mL of water. For dry samples add 10 ml of

water.

(

2

) Add 100 ml of Methanol (HPLC-grade), and cap.

(

3

) Mix by shaking until well dispersed. Place flask on

shaking table at 37°C for 12 h. adjust shaking to obtain good

mixing.

(

4

) Cool to ambient temperature.

(

5

) Accurately weigh the extraction vessel.

(

6

) Transfer part of the extraction liquid to a 50 mL

centrifuge tube, and cap.

(

7

) Centrifuge the extraction liquid to obtain a clear liquid,

(approximately 200 rpm for 10 min).

(

d

) Determination of free carnitine -

(

1

) For high concentration samples a dilution step with water

should be performed before addition of the internal standard.

(

2

) Accurately weigh the digestion vessels.

(

3

) Transfer 1 – 5 g accurately weighed, of the clear

extraction liquid to the digestion vessels.

(

4

) Add 10 g accurately weighed ISTD standard solution to

the digestion vessels.

(

5

) Dilute to 250 mL volume with water and accurately

weight the solution. Cap and mix well. Transfer to an auto-

sampler vial and cap.

(

e

) Determination of Total carnitine and –

(

1

) For high concentration samples a dilution step with water

should be performed before addition of the internal standard..

(

2

) Accurately weigh the digestion vessels.

(

3

) Transfer 1 – 5 g accurately weighed, of the clear

extraction liquid to the digestion vessels.

(

4

) Add 10 g accurately weighed ISTD standard solution to

the digestion vessels.

(

5

) Add 3 mL of 2M Potassium hydroxide solution, and 47

mL of water, close with stopper.

(

6

) Hydrolyse in oven at 102°C for 4 h.

(

7

) Cool to ambient temperature.

(

8

) Add 4 mL 1.6M Hydrochloric acid

(

9

) Dilute to 250 mL volume with water and accurately

weight the solution. Cap and mix well. Transfer to an

autosampler vial and cap.

G. Instrument operation conditions

(

a

) LC. – Isocratic run 0-2 min. 98% A; 2% B. Flow 0,5

mL/min; injection volume, 2 μL; column temperature, 25°C;

autosampler temperature, ambient.

(

b

) MS/MS.—Ionization mode, positive-ion electrospray

ionization (ESI+);Curtain gas, 30 psi;Collision gas, Med;

Ionspray voltage , 5.5 kV; source temperature, 700°C; Ion

Source Gas 1, 65 psi;Ion source gas 2, 65 psi.

(

c

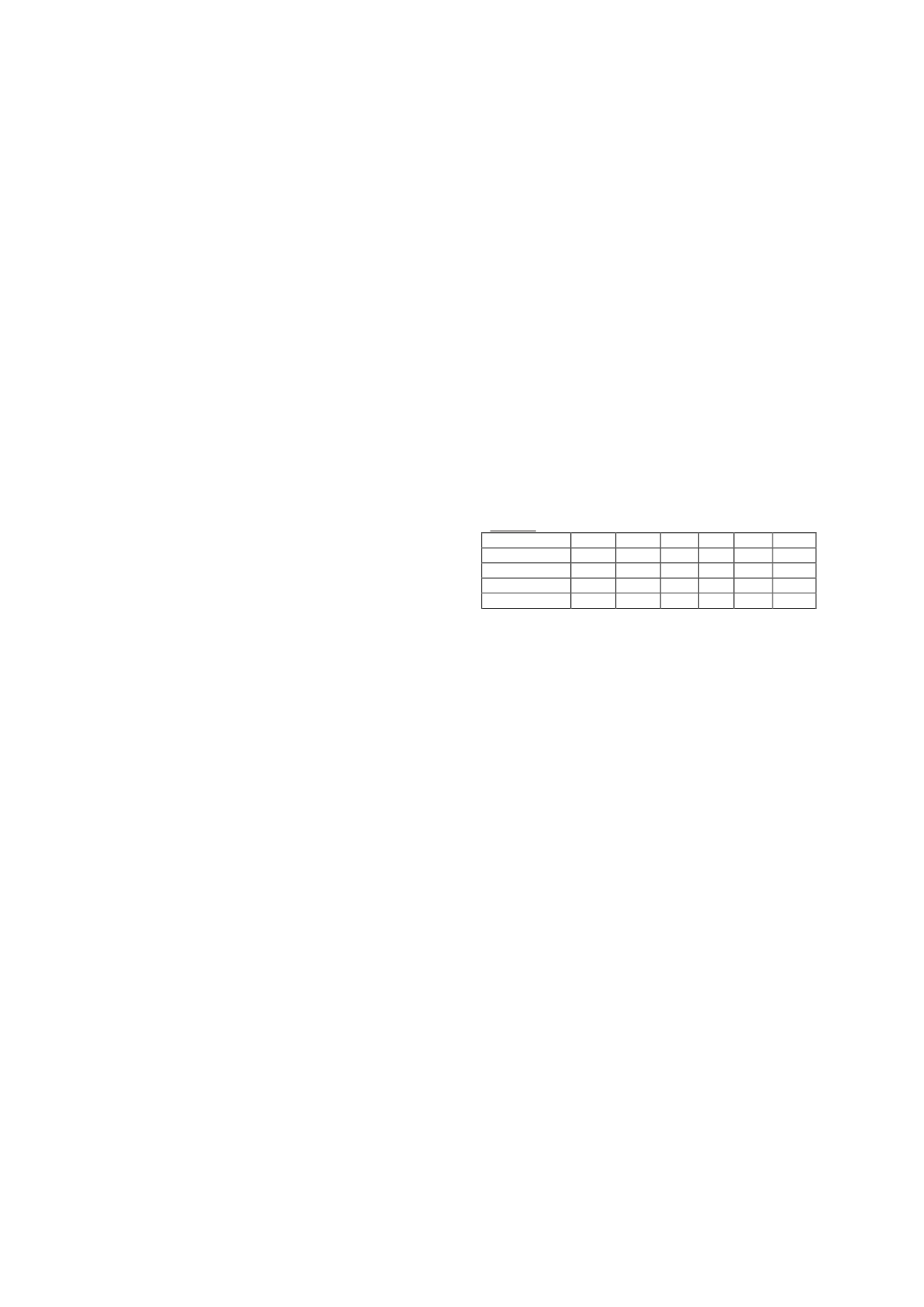

) Parameters for MS/MS measurement see table 1.

Table 1.

Analyte

Q1

a

Q3

b

DP

c

EP

d

CE

e

CXP

f

L-carnitine

162.2 103.1 36.0

5.0 19.0

4.0

L-carnitine

162.2

85.1 36.0

5.0 25.0

4.0

L-Carnitine-d

3

165.2 103.1 36.0

5.0 19.0

4.0

L-Carnitine-d

3

165.2

85.1 36.0

5.0 25.0

4.0

a

Q1 = Quadrupole mass filter 1.

b

Q3 = Quadrupole mass filter 3.

c

DP = Declustering potential.

d

EP = Entrance potential.

e

CE = Collision energy.

f

CXP = Collision cell exit potential.

(

d

) Data acquisition was done in the multiple-reaction

monitoring (MRM) mode.

(

e

) Quantitation of L-carnitine.—The MRM chromatogram

for L-carnitine is a sum of signals for the transitions m/z 162

> 103 and 162 > 85. Likewise, the MRM chromatogram for

the ISTD is a sum of signals for the transitions m/z 165 > 103

and 165 > 85. Analyst automatically calculates a response

ratio, which is defined as the L-carnitine peak area divided by

the ISTD peak area.

(

f

) UPLC analysis.—After verifying equilibration of the

UPLC system, inject the working standards (L1 to L6)

followed by a reagent blank, control sample, and sample

extracts.

(

g

) Inject working standards after approximately every 20

sample extraction, injected after the analysis of the last

sample extract. Notes: Calibration curves must have a

correlation coefficient r

2

of >0.990.

H. Calculation of results

(

a

) Manual calculations.—

(

1

) Plot each calibration standard response ratio versus its

corresponding concentration to obtain calibration curves for

L-carnitine. Apply a nonweighted linear regression to the

data, and obtain an equation for the best-fit line.

Carn-06

FOR ERP USE ONLY

DO NOT DISTRIBUTE