gently restored to its original state, and will form part of the new

structure. This is in line with Heatherwick’s vision to celebrate

the industrial history and heritage of the structure.

Structural core

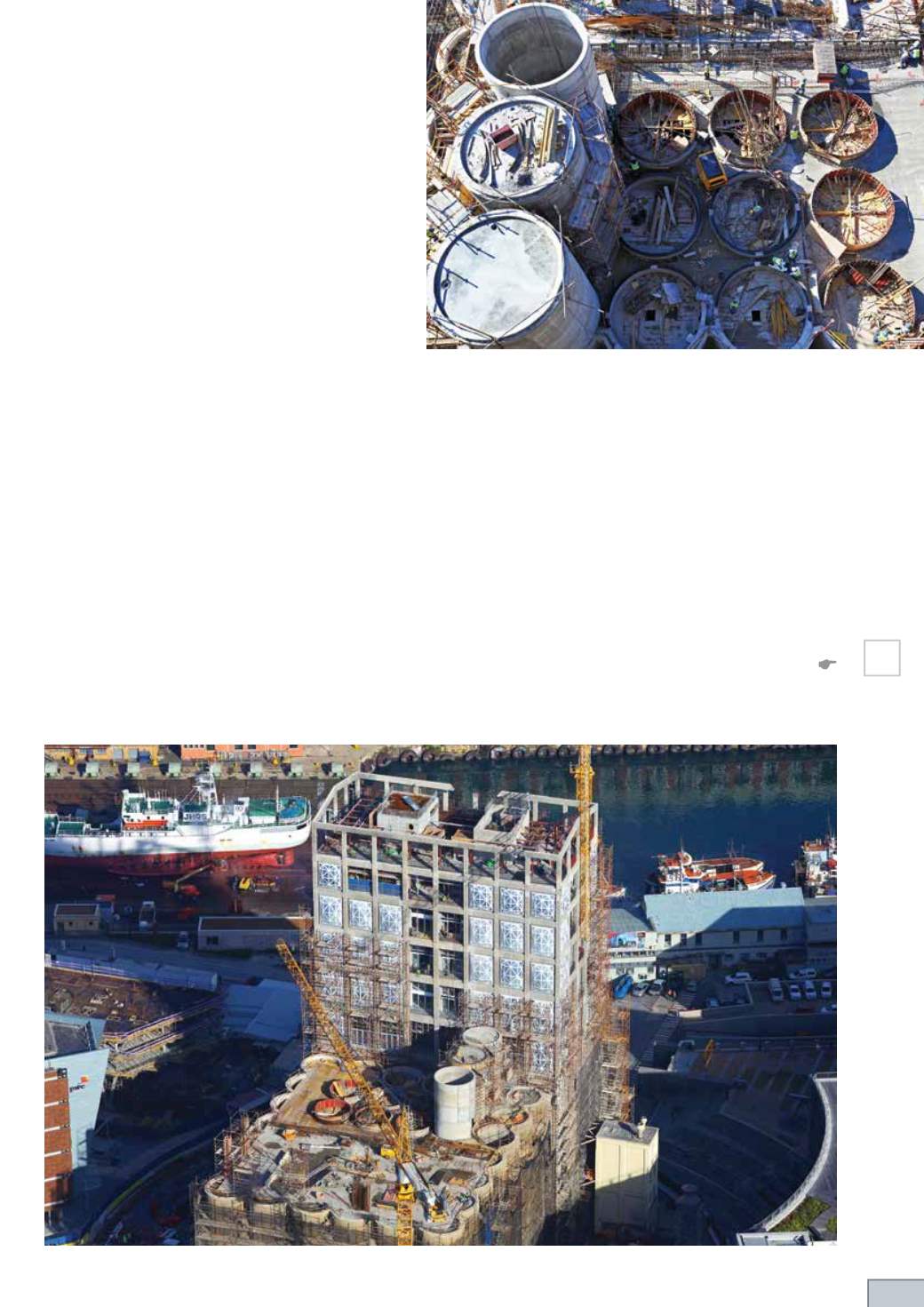

To create the structural core of the elevator building, two

parallel activities commenced at the start of the project. Firstly,

demolition of the ground floor slab and basement to four

metres below sea level to create the structural opening of the

new northern and southern cores was started. Simultaneously,

a mining project from the top of the silo bins (Level 6) started

to cut through the centre of the elevator building to create the

space for the cores. This mining task was programmed to reach

Level 1 at the same time as the cores, which were by then under

construction from the basement up, reached the underside of

Level 1 and then continued up through the building to Level 11.

As the cores progressed up through the building the construction

team could drop back down and start the process of tying the building

into the cores. Once this process was complete the remaining activities

could commence, namely the demolition of the remainder of the square

bins and the installation of the pillowed façade above Level 6.

The pillowed façades are manufactured in Cape Town from a steel

frame and are clad with 54 pieces of triangulated soft coated high perfor-

mance double glazed units. Each unit weighs approximately 500 kg.

There are five different types with the largest being over 20 m

2

in size.

Creating the museum

Before carving and cutting activities could commence to form the atrium

and museum, the 42 circular silo bins in the adjacent storage annex had

ZEITZ MOCAA

This resleeving process required concrete form work to be specifically constructed

to the internal shape of the bins; this was then lowered into the bins by crane and

concrete poured from the base up in a number of stages. This process was also

required to form the new structure for the atrium in the centre of the building.

The pillowed façades are manufactured in Cape Town from a steel frame and are clad with 54 pieces of triangulated soft coated high performance double glazed

units. Each unit weighs approximately 500 kg. There are five different types with the largest being over 20 m

2

in size.

to be thoroughly cleaned. Workers had to physically cut a warren of

walkways through the bins to access all areas without damaging any of

the bins that were to remain in the finished product.

Once the circular bins had been cleaned and made safe, the process

of reinforcing could commence. The structure, being over 90 years old,

was designed solely to store grain. The strength of the structure was by

virtue of its tubular form and the fact that each tube was connected to

the next to form a honeycomb type structure. This gave the building

all the vertical reinforcement that it required and only horizontal

reinforcement was used when the building was constructed in 1924,

principally to withstand the horizontal pressure imposed by the grain

within the silo bins.

In order to construct the museum inside the silo bins, a new building

had to be constructed within the old. This could only be done once the

5

CONSTRUCTION WORLD

DECEMBER

2016