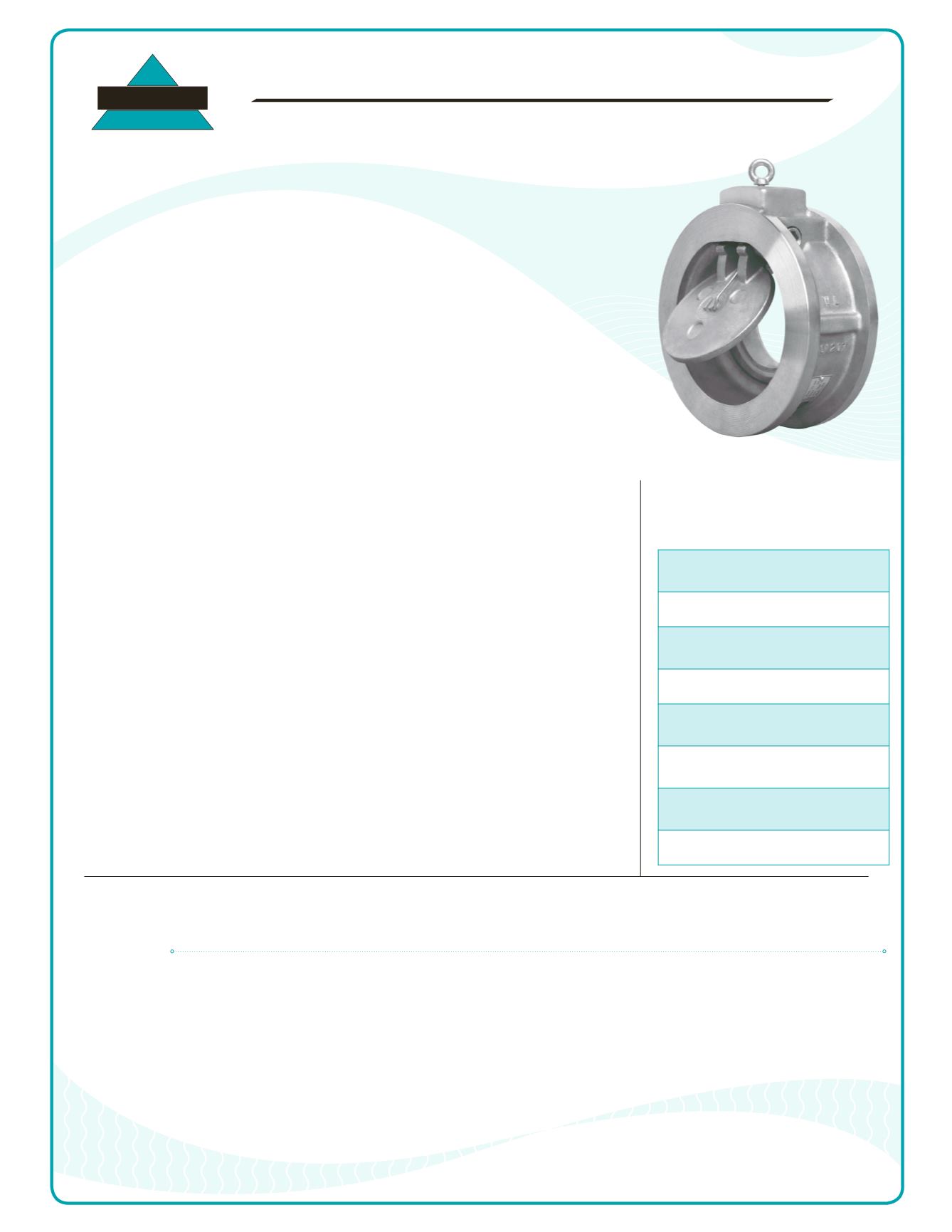

SWING CHECK VALVE

f

WAFER TYPE

f

SINGLE DISC

ANSI CLASS

150

f

CARBON AND STAINLESS STEEL

CV32-0617

T

TECHNICAL

TITAN

TITAN FLOW CONTROL, INC.

F

FEATURES

Tel: 910-735-0000

s

Fax: 910-738-3848

s

titan@titanfci.coms

www.titanfci.com290 Corporate Drive

s

PO Box 7408

s

Lumberton, NC 28358

YOUR PIPELINE TO THE FUTURE!

TITAN FLOW CONTROL, INC.

s

economi cal

des ign

low

we i ght

and

short

lay i ng

l ength

p roduce

s av i ngs

i n

i n i t i al

cos t

,

s pace

r equ i r ement s

,

and

i ns tal lat i on

when

compar ed

to

ful l

-

body

,

swi ng

-

ty p e

check

valv e s

.

s

minimal

head

loss

head

los s

i s

m i n i m i zed

by

p rov i d i ng

a

short

,

s tra i ght

and

v i rtual ly

unob s truct ed

f low

path

.

add i t i onal ly

,

the

s p r i ng

-

loaded

d i sc

i s

de s i gned

wi th

v e ry

low

crack i ng

p r e s sur e

wh i ch

r educe s

the

amount

of

ene rgy

r equ i r ed

to

op en

the

valv e

.

s

qui ck

closure

to

reduce

water

hammer

shut

-

of f

i s

ach i e v ed

v i a

the

ful ly

automat i c

,

s p r i ng

-

a s s i s t ed

d i sc

that

clos e s

near

ze ro

f low

v e loc i ty

.

the

l i ghtwe i ght

,

s i ngl e

d i sc

de s i gn

cr eat e s

a

pos i t i v e

shutof f

p r i or

to

f low

r e v e r s al

wh i ch

he l p s

to

ke e p

surge s

to

a

m i n i mum

.

s

durable

,

high

qual i ty

des ign

the

cv32 check

valv e

i s

ava i lab l e

i n

e i the r

carbon

s t e e l

or

s ta i nl e s s

s t e e l

body

conf i gurat i ons

,

wh i ch

al low

i t

to

p e r form

we l l

i n

h i ghe r

t emp e ratur e

ap p l i cat i ons

.

the

carbon

s t e e l

un i t s

ar e

e poxy

pa i nt ed

.

add i t i onal ly

,

both

mode l s

f eatur e

ant i

-

corros i v e

,

s ta i nl e s s

s t e e l

tr i m

(

d i sc

,

s p r i ng

,

sha f t

)

a s

s tandard

.

s

res i l i ent

soft

seats

r e s i l i ent

sof t

s eat s

(

v i ton

and

p t f e

o

-

r i ng

)

coup l ed

wi th

p r ec i s i on

mach i ned

s eal i ng

sur face s

he l p

to

ensur e

a

bub b l e

t i ght

s eal

that

me e t s

or

exce eds

ap i

598

t e s t

r equ i r ement s

.

A

APPLICATIONS

MODELS: CV 32-CS

(Carbon - Vi ton)

CV 32-SS

( S t a i n l es s - PTFE)

S IZES : 2" ~ 12"

PRESSURE/ TEMPERATURE RATING

CS - ASTMA216 G

r

.WCB - CLASS 150

WOG

(Non-shock)

: 285 PSI @ 100 °F

PRESSURE/ TEMPERATURE RATING

SS - ASTMA351 G

r

. CF8M - CLASS 150

WOG

(Non-shock)

: 275 PSI @ 100 °F

SEAT MATERIAL (O-RING)

TEMPERATURE RANGE

VITON: -40 ~ 400 °F

PTFE: 14 ~ 248 °F

SPRING MATERIAL

MAXIMUMTEMPERATURE

Series 300 Stainless Steel: 450 °F

markets

:

general

industry

,

chemical

,

petrochemical

,

power

,

and

food

&

beverage

service

:

intended

for

liquid

service

that

is

steady

,

clean

(

no

abrasives

or

solids

)

and

non

-

pulsating

.

flow

rate

should

not

exceed

15

ft

/

sec

.

not

recommended

for

steam

or

reciprocating

compressor

service

.

ptfe

properties

:

recommended

for

most

chemical

environments

including

acids

,

b ases

,

oils

,

steam

and

other

process

fluids

.

offers

excellent

tear

,

abrasive

,

chemical

,

acid

,

and

alkali

resistance

.

not

recommended

for

high

pressure

steam

or

large

temperature

variation

applications

.

viton

properties

:

offers

a

broad

range

of

chemical

resistance

and

excellent

heat

resistance

.

good

mechanical

properties

and

compression

set

resistance

.

often

used

in

applications

where

nothing

else

will

work

.

fair

low

temperature

resistance

and

limited

hot

-

water

resistance

and

shrinkage

.

The above data represents common market and service applications. No representation or guarantee, expressed or implied, is given due to the numerous

variations of concentrations, temperatures and flow conditions that may occur during actual service.