April - May 2016

MODERN QUARRYING

11

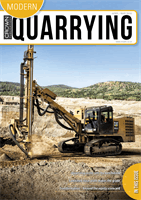

The MD5075C has the largest

pattern coverage in its class, a fast

rod changer for improved cycle

times, fast tram times from hole to

hole and a comfortable cab with an

improved operator interface.

ON THE

COVER

and electronics-free rod changer (free of

sensitive sensors that can cause excessive

downtime), and a Cat-engineered power

train with matched horsepower.

Major components are built to last

the life of the machine, and Caterpillar is

the only manufacturer offering rock drills

designed to be serviced on-site.

“One hundred percent of all rock

drill services can be completed without

removing the drill from the feed,”explains

Barloworld Equipment Cat drill product

manager, Ramon Glaus, adding that the

drills are equipped with Cat ET (Electronic

Technician) diagnostic software to

quickly troubleshoot the entire machine.

Barloworld Equipment is the Cat dealer

for Southern Africa.

“With up to three times the lifespan

and less than one half the parts cost of

competitive rock drills, Cat units deliver

with maximum uptime at an overall low

total cost of ownership.”

At the business end, the new Cat

MD5075C is capable of drilling 76,2 mm

to 114,3 mm diameter holes to a depth of

31,2 m. The standard rock drill for this unit

is the 23 kW HPR5123, which accepts 45

or 51 mm drill steel. Also available is the

HPR4519 rock drill, which uses a 45 mm

drill rod specification. The compressor,

which features widely variable air control,

produces 9,9 m

3

/min @ 10,2 bar.

“Thanks to industry-leading pattern

coverage, the MD5075C is able to drill up

to three to four holes per set-up before

having to tram and reposition,” Glaus

expands.

Power delivery is via a Cat C9 engine

rated at 224 kW with machine mobility

provided by a reliable Cat 315E undercar-

riage that can be rebuilt. Track assemblies,

fitted with 380 mm triple grousers, are

hydraulic motor driven, ensuring fast and

smooth tram speeds over rough terrain.

The standard rock drill for the Cat MD5075C is

the 23 kW HPR5123, which accepts 45 or

51 mm drill steel.

Largest in class, the Cat MD5075C has a 3,81 m boom, plus a 1,5 m boom extension. This

keeps operators a total of 5 334 m away from a ledge or highwall. The boom is constructed

of thick square tubing with steel plate reinforcements in key areas to add strength.