Mechanical Technology — March 2016

5

⎪

On the cover

⎪

A Linatex-lined Isogate mechanical pinch valve.

our equipment design knowledge and ex-

pertise in analysis algorithms to produce

robust equipment and process specific

performance classifiers,” he explains.

Continuous condition monitoring of

specific mining processes, according to

Mdlazi, is relatively rare. Process and

equipment monitoring is mostly based on

irregular or periodic manual inspections

that have been found to be somewhat

ineffective in picking up or predicting

incipient equipment failure. “Imminent

failure can easily be missed unless each

asset is automatically and continuously

being monitored,” he suggests.

Describing how Synertrex monitor-

ing systems work, he says that each

machine is connected to its own moni-

toring module, which collects vibration,

temperature, flow, pressure and wear

data along with process specific process

performance indicators. “All of this data

is sent via a local Wi-Fi network to be

collated and analysed onsite. Associated

analysis software algorithms embedded

into the system are used to trend equip-

ment condition and deterioration and

to trigger alarms should the signatures

be outside those of normally operating

machines,” he says.

The system also includes enterprise-

level or big-data connectivity. Using

ADSL, satellite or 3G/4G Internet proto-

cols, all of the results from the site can

be uploaded to the Internet and remotely

accessed via ERPs (enterprise resource

planning systems) or other dedicated

software applications.

“This system is designed for clients

that require more from their equipment,

to enable them to reliably minimise

maintenance costs, improve uptime and

reduce their total costs of ownership,”

Mdlazi tells

MechTech

.

“We are increasingly being asked to

guarantee the performance numbers

and lifetime claims of our equipment.

Our Synertrex system will allow us to

collect credible data about machines

operating in each different environment.

In addition to helping us improve our

designs, monitoring allows us to proac-

tively intervene where equipment is not

performing optimally in order to avoid

downtime and redress performance is-

sues,” adds Stehle.

“This is also an ideal tool to support

our service contract offerings. When Weir

Minerals’ takes on service responsibili-

ties, we do so at a fixed cost to the cus-

tomer and penalties apply for excessive

downtime. It is therefore in our direct

interest to track a machine’s condition

to maximise productivity and uptime

for our clients and reduce risk to us,”

explains Stehle.

“Ultimately, we want to go beyond

condition monitoring and, in the long

term, use the principles of the ‘Internet

of Things’ and ‘big data analytics’, to

develop predictive algorithms that can

optimise and control plant performance

– by analysing the ongoing performance

of individual machines, identifying bottle-

necks and under capacity and setting

each machine’s individual output for

maximum capacity at lowest total costs,

for example,” says Mdlazi.

Turning attention to the potential use

of Synertrex systems for slurry pumps,

Gomes points out that a pump’s ef-

ficiency falls as the impeller and the

throat bush wear. “This knowledge can

be incorporated via Synertrex to predict

the best time to refurbish a pump, based

on minimising the TCO,” he explains.

“The industry has developed ways of

compensating for production losses as

a pump wears by increasing the pump

speed using variable speed drives (VSDs).

By monitoring these aspects, it is pos-

sible to determine how well the pump is

performing and how quickly it is wearing.

This is directly useable for optimising

predictive maintenance schedules, for

example,” Gomes tells

MechTech

.

“The Synertrex development will en-

able us to gather life and efficiency data

for a host of different applications and

environments. In addition, we will be able

to use reliable real-time data to perform

just-in-time maintenance, instead of

having to risk failure by leaving a pump

running too long or wasting significant

amounts of wear life by changing out the

impellers and throatbushes too early,”

Gomes concludes.

q

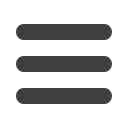

Weir Minerals’ Isando-based enigineering department is the DCO for Enduron vibrating screens.

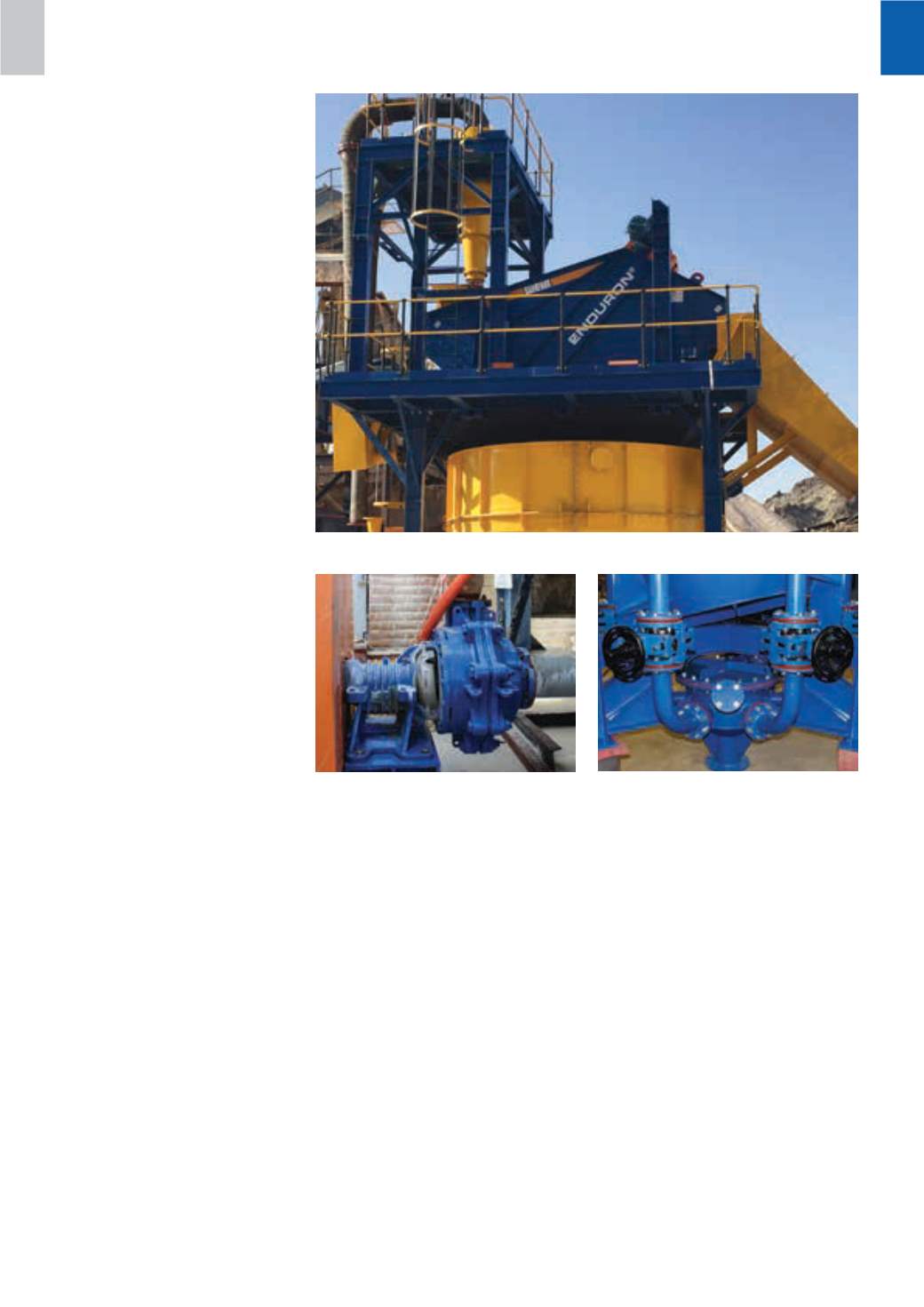

The new Warman WBH slurry pump.