www.read-tpt.com

www.read-tpt.com

120

M

ay

2012

A

rticle

The development of AUTO-

DNSA mills and ERW tube mills

By Guowu Gao, chief engineer, FD Machinery, China

THE fact that the global economy is in a downturn makes investors

for ERW tube mills more cautious. Only a company with sound

economic strength and a stable market would consider making an

investment to either build new lines or renovate the equipment,

while there will be less speculative investment.

Those companies have used many types of equipment that are

new, old, advanced or obsolete, which enables them to accumulate

useful experience in judging the quality of the equipment to help

them select their favourite equipment for the future. Although the

experience is useful in making a judgment it is not always enough

because the technologies have been advancing continuously

and people’s understanding usually lags behind the technological

development. Buyers hope to purchase cost-effective equipment

with good performance and may also hope to make a useful

investment while others stop investing to create an opportunity to

beat competitors.

However, the understanding of equipment does differ due to the

different background, experience, area of the world and interest.

Some companies would choose the equipment that can simply

get the tube produced. Some would tend to favour equipment

they have used in the past. Some with low labour cost and poor

technology prefer simple equipment. Tube mill manufacturers,

of course, often like their own equipment. Therefore, this paper

will make an objective judgment on the equipment from a purely

technological point of view, which

will be helpful for the buyers to

better understand the equipment

and choose the equipment that

best suits their needs.

The buyers of any equipment will

face the issue of employees. For

a production line, the technical

capacity of the employees has

a direct impact on the returns

of an enterprise. You can often

be taken by surprise by some

enterprises that have built large

plant buildings and installed many

production lines. Only one size

product is produced by each line,

so this line is operated if the order

is placed for this product, while

other lines stop without any roller

change or testing.

This approach is not suitable

for most tube welding plants,

because not only has the profit

been eaten by the plant area, but

you can also never have enough

production lines to match the

number of products of different

specifications.

However, there must be some

reason for such an enterprise to

exist. If we ponder the reasons,

we would find it is because the

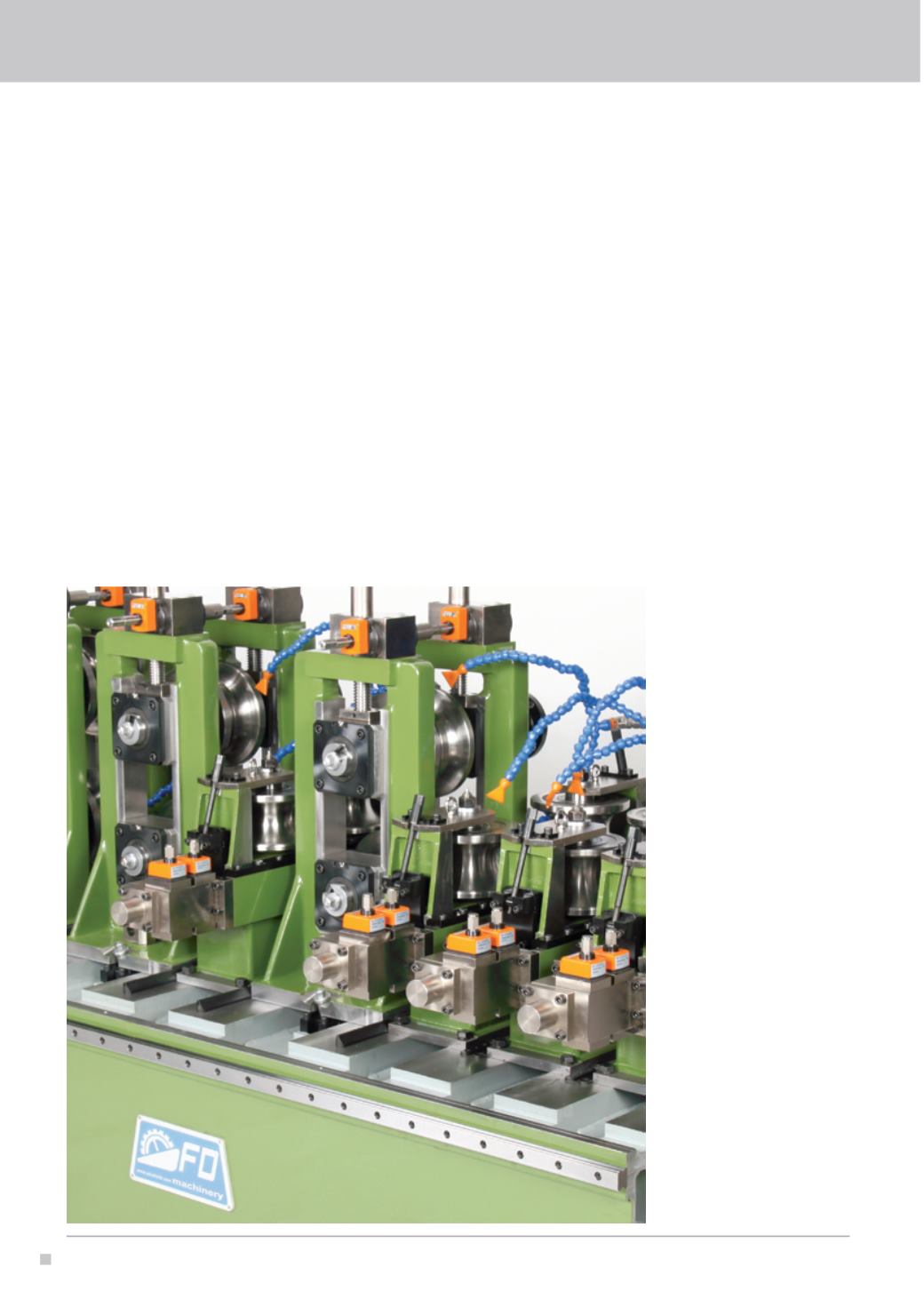

DNSA mill: Horizontal stand and vertical roll stand